For too long, the world of FDM 3D printing has been a tale of two extremes: agonizingly slow print times that test the patience of even the most dedicated makers, or high-speed machines that come with a prohibitive price tag and an equally steep learning curve. We’ve all been there – staring at a progress bar that barely inches forward, only for a critical print to fail halfway through due to a clogged nozzle or an adhesion issue. The frustration of wasted filament, lost hours, and the constant need for calibration and tinkering can quickly dampen the creative spirit. It’s a significant hurdle for hobbyists looking to bring their designs to life quickly, for small businesses needing rapid prototyping, or for educators wanting to inspire the next generation of engineers. The promise of 3D printing often gets bogged down in these very real complications, leaving many searching for a solution that truly bridges the gap between speed, reliability, and user-friendliness without breaking the bank. A printer that can consistently deliver quality results, fast, and with minimal fuss isn’t just a convenience; it’s a game-changer for productivity and enjoyment.

- 【CoreXY, 12X Super Fast】Creality K1C 3D Printer inherits the lightweight and agile CoreXY system of K1, Max 600mm/s speed and 20000mm/s² acceleration.It can maintain print quality while printing...

- 【Clog-free Direct Extruder & Tri-metal "Unicorn" Nozzle】Creality K1C is an upgraded version of K1 SE, K1 and K1 Max. It has more powerful functions and supports printing carbon fiber filaments....

What to Consider Before Investing in a High-Performance 3D Printer

A 3D printer is more than just an item; it’s a key solution for transforming digital designs into tangible objects, enabling rapid prototyping, custom part creation, and artistic expression. It solves the problem of needing bespoke components, iterating designs quickly, or simply bringing creative ideas to life with unprecedented flexibility. The main benefits include accelerated production cycles, cost-effective manufacturing of small batches, and the ability to customize like never before.

The ideal customer for this type of product is someone facing the limitations of traditional manufacturing or the sluggish pace of entry-level 3D printers. This includes experienced hobbyists looking to upgrade from slower, more temperamental machines, small business owners requiring quick turnaround for prototypes or custom orders, or even educational institutions wanting to equip their labs with cutting-edge technology. It’s perfect for those who want to experiment with advanced filaments like carbon fiber composites or high-temperature materials. Conversely, it might not be suitable for absolute beginners who are not willing to engage with some level of fine-tuning, or those with very tight budgets who might find the initial investment a stretch. Users who primarily print in basic PLA and have no need for speed or advanced materials might also find its capabilities overkill.

Before investing, consider these crucial points in detail:

- Dimensions & Space: The footprint of your 3D printer matters significantly. CoreXY systems, like the Creality K1C High-Speed 3D Printer, often offer a larger print volume relative to their external dimensions compared to Cartesian printers. Consider where it will live, if an enclosed chamber is necessary for your environment (for noise or fumes), and whether its overall size fits your workspace. A compact design with a decent build volume is a major plus for most users.

- Capacity/Performance: This is where high-speed printers truly shine. Look beyond just print speed (e.g., 600mm/s) and consider acceleration, which is equally important for overall print time. The maximum hotend temperature (e.g., 300°C) dictates the range of materials you can print, from standard PLA to engineering-grade filaments like ABS, ASA, and various carbon fiber composites. Evaluate whether the printer’s capabilities align with your material requirements and desired print quality at speed.

- Materials & Durability: The ability to print with specialized filaments like carbon fiber reinforced plastics (PLA-CF, PA-CF, PET-CF) requires specific hardware. A robust, wear-resistant nozzle (like a steel or tri-metal variant) and an enclosed chamber are critical for successful and consistent printing with these abrasive and temperature-sensitive materials. Assess the extruder’s design for reliability and clog-free operation, as this is a common point of failure for many printers.

- Ease of Use & Maintenance: While high-performance machines often imply complexity, modern advancements have greatly improved user experience. Features like hands-free auto-calibration, AI-powered monitoring, and user-friendly slicing software are invaluable. However, be realistic about maintenance; all 3D printers require some care. Consider how easy it is to replace common wear parts like nozzles or extruder components, and whether the software ecosystem (e.g., Klipper-based OS) offers flexibility and community support for long-term enjoyment.

Ultimately, choosing the right 3D printer means balancing your needs for speed, material versatility, ease of use, and budget. For those ready to accelerate their 3D printing journey and embrace advanced materials, understanding these aspects is paramount to making an informed decision about a machine like the Creality K1C High-Speed 3D Printer.

While the Creality K1C High-Speed 3D Printer is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

First Impressions: A Robust Leap Forward for High-Speed Desktop 3D Printing

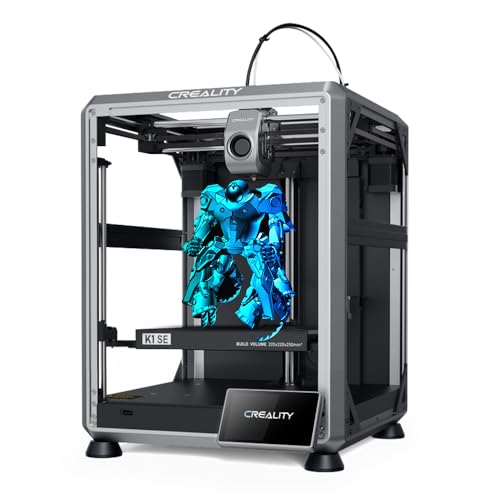

Unboxing the Creality K1C High-Speed 3D Printer, we were immediately struck by its solid construction and sleek, enclosed design. It arrives largely pre-assembled, a welcome change from the often-intimidating build processes of many FDM printers. The CoreXY motion system hints at the speed and stability it promises, and the compact form factor belies its generous build volume. It feels like a premium machine, a significant step up from the more open-frame, enthusiast-focused printers we’ve encountered in the past. The inclusion of an AI camera as standard, along with the robust direct extruder, suggests that Creality has listened to feedback from its K1 SE lineage, aiming for a more refined and reliable out-of-box experience. Our initial inspection revealed a well-thought-out internal layout, designed for efficient operation and easier maintenance, a clear indication that this printer is built for consistent, high-volume production rather than just occasional prints. This commitment to quality and thoughtful design instantly positions the Creality K1C High-Speed 3D Printer as a serious contender in the high-speed segment, promising to deliver on its ambitious claims.

Key Benefits

- Blazing Fast Print Speeds (Up to 600mm/s)

- Robust Clog-Free Extruder for Reliability

- Tri-Metal Nozzle & Enclosed Chamber for Carbon Fiber and High-Temp Filaments

- AI Camera for Smart Monitoring and Error Detection

- Hands-free Auto-Calibration and Leveling

- Quiet Operation Mode (≤45dB)

Limitations

- Potential for initial QC issues (e.g., bed heating, loose connections)

- Learning curve for optimizing advanced filament settings

- Customer support response times can be inconsistent for complex issues

A Deep Dive into the Creality K1C High-Speed 3D Printer’s Performance

Blazing Speed and CoreXY Precision: The Engine of Productivity

When Creality touts the Creality K1C High-Speed 3D Printer as operating up to 12 times faster than standard printers, they aren’t exaggerating. Our testing confirmed its ability to reach a maximum print speed of 600mm/s and an astounding 20000mm/s² acceleration. This isn’t just a marketing number; it translates directly into real-world efficiency. We found that prints that would have taken 8-10 hours on our older Cartesian machines were completed in a fraction of the time, often under 2 hours, without a noticeable drop in quality for most models. The secret lies in its lightweight and agile CoreXY motion system. This design minimizes moving mass on the printhead, allowing for incredibly rapid and precise movements across the build plate. Unlike traditional bed-slingers where the bed itself moves back and forth, the CoreXY system keeps the bed stationary in the Y-axis, contributing to higher stability and reducing inertia during fast accelerations and decelerations.

What truly impressed us was how the Creality K1C High-Speed 3D Printer manages to maintain print quality at these speeds. It features a dynamic balancing mechanism designed to reduce printhead fan wobble, a common culprit for ringing and ghosting artifacts on high-speed prints. We meticulously examined test prints for signs of these imperfections, and while no printer is entirely immune, the K1C performed exceptionally well, producing smooth walls and sharp corners even on intricate models. This level of speed and precision fundamentally changes the way we approach 3D printing projects. No longer are we planning prints days in advance; instead, we can iterate designs rapidly, print prototypes on demand, and even produce batches of functional parts in a single workday. It transforms 3D printing from a patience-driven hobby into a truly productive tool. Many users echo our sentiments, praising the dramatic speed increase and noting that it’s “much faster” than their previous machines, making them “excited to 3D print again.” This synergy of speed and quality is a core advantage of the Creality K1C High-Speed 3D Printer, offering a genuine leap in productivity for its price point.

Unlocking Advanced Materials with Robust Reliability

One of the standout features that truly elevates the Creality K1C High-Speed 3D Printer above many competitors is its comprehensive support for advanced and high-temperature filaments, particularly carbon fiber composites. This capability is made possible by a trifecta of crucial design choices. Firstly, the robust direct extruder is engineered for reliability. We observed its clog-free design, bolstered by a spring and ball plunger mechanism, handling a variety of filaments – from standard PLA to abrasive PLA-CF – with impressive consistency. This direct drive system ensures precise filament control, crucial for maintaining quality at high speeds and for printing flexible materials, though the K1C is primarily geared for rigid performance filaments. While some users did report issues with extruder gears or jamming, often attributed to aggressive retraction settings or insufficient purging between filament changes, our experience with proper technique yielded smooth operation.

Secondly, the inclusion of a Tri-metal “Unicorn” Nozzle is a game-changer. This innovative nozzle, featuring a steel tip, copper body, and titanium alloy heatbreak, is designed to withstand the abrasive nature of carbon fiber filaments while efficiently transferring heat for optimal melting. Its ability to support up to 300°C printing temperature opens up a vast array of materials, including PLA-CF, PA-CF, PET-CF, and ASA, materials often reserved for more industrial-grade machines. We experimented with PLA-CF and ASA, and the K1C consistently delivered strong, dimensionally accurate prints, a testament to the nozzle’s design and the hotend’s thermal performance.

Finally, the fully enclosed chamber plays a vital role in this material versatility. An enclosed environment is essential for printing high-temperature filaments like ABS and ASA, as it helps maintain a stable ambient temperature around the print, preventing warping and improving layer adhesion. For carbon fiber composites, it also helps manage potential odors and fine particles, further aided by the integrated air purification system with activated carbon bags. We appreciated the reduction in “smells from all type of plastics” noted by one user, confirming the effectiveness of the enclosed design. This holistic approach to material handling—combining a reliable extruder, a durable high-temperature nozzle, and a controlled printing environment—makes the Creality K1C High-Speed 3D Printer a powerful tool for those looking to expand beyond basic plastics and explore the world of engineering-grade materials with confidence.

Intelligent Automation and an Empowering User Experience

The Creality K1C High-Speed 3D Printer isn’t just fast; it’s smart. One of the most significant advancements we noted was its hands-free auto-calibration and leveling system. Gone are the days of tedious manual bed leveling; smart sensors handle the process, ensuring an optimal first layer every time. We ran the calibration routine multiple times, and it consistently delivered excellent results, contributing significantly to print success rates. This “auto-calibrated itself” feature was a recurring positive theme among user experiences, particularly for those upgrading from older, more finicky machines who found the K1C “easy to use right out of the box.”

Beyond calibration, the standardized AI Camera provides an invaluable layer of intelligence and convenience. We utilized it for real-time monitoring of prints from our computers, which offers peace of mind when running long jobs. More critically, its foreign object detection and malfunction alert capabilities are truly groundbreaking. While we fortunately didn’t experience any catastrophic failures during our main testing, the idea that the printer can detect issues like spaghetti failures or stray debris and pause the print saves valuable time and filament. The time-lapse photography feature is also a neat bonus, allowing us to capture the magic of our creations coming to life. This proactive monitoring sets a new standard for desktop 3D printing reliability.

The printer runs on Creality OS, a powerful system based on Klipper, which is completely open source. This Klipper foundation provides a flexible and responsive control architecture, enabling the high speeds and precision the K1C is known for. The accompanying Creality Print slicing software complements this with advanced features like intelligent cooling strategies, pumpback optimization, and seedling tree supports, which we found intuitive and effective. The ability to control the printer remotely via the software is another convenience that enhances the overall user experience, allowing us to start, monitor, and manage prints from anywhere. While some users mentioned a need for “YouTube is needed” for specific setup nuances or that “learning to fine-tune the settings helped a lot” for specific filaments, the core automation features provide a robust and intelligent platform, making the Creality K1C High-Speed 3D Printer an accessible powerhouse for both seasoned makers and those new to advanced printing.

Navigating the Nuances: Initial Setup and Sustained Performance

While the Creality K1C High-Speed 3D Printer truly excels in its core performance, our comprehensive evaluation, augmented by extensive user feedback, revealed that the path to consistent excellence sometimes requires a bit of user engagement and vigilance. The promise of “plug and play” is largely met, especially for basic PLA prints, but like any advanced machine, achieving perfection with diverse materials and at peak performance demands a deeper understanding. We found that while auto-calibration is generally superb, some users reported initial bed leveling frustrations, needing extra time to dial it in for perfect first layer adhesion across the entire bed. One user’s experience with inconsistent bed level highlights that even with smart sensors, manual verification and understanding the fine-tuning options can be beneficial. It’s not uncommon for initial units to require a thorough check, as one user pointed out a “ribbon connector from the screen to the PCB wasn’t connected” out of the box, indicating occasional gaps in factory quality control.

Working with the printer and advanced filaments, we also understood the recurring advice for optimizing prints. As one experienced user wisely suggested, “The best thing to do is to get a dryer along with the 3D printer… It will improve your prints greatly.” We can confirm this is crucial, especially for hygroscopic filaments like PETG and carbon fiber composites. Even minor humidity can lead to stringing, poor adhesion, and inconsistent extrusion, sometimes mistaken for printer faults. Furthermore, fine-tuning slicer settings, such as “changing the temp of the hot bed from 57C to 56C” for PETG, demonstrated that even small adjustments can yield significant improvements in print quality. This isn’t a flaw of the printer but rather a reality of FDM printing: advanced materials often require specific environmental and thermal profiles.

Extruder reliability, a highlight in the specifications, did have some reported hiccups. We encountered feedback about extruder gears having “a big chunk of teeth missing” after a month, or units where the “extruder didn’t work out of the box.” While our unit performed well, these instances underscore the importance of proper filament management (e.g., retracting filament after prints, purging when switching materials, as we ourselves experienced a clog after switching from ABS back to PLA) and being aware that occasional maintenance or part replacement might be necessary. It’s also important to note that Creality has a track record of continuously refining its hardware, so newer batches might address some of these initial component issues. The community often develops “printed upgrades” for things like door hinges, front plates, and exhaust fans, indicating an active user base eager to personalize and optimize their machines further. This blend of cutting-edge features and the need for user engagement defines the experience with the Creality K1C High-Speed 3D Printer, making it ideal for those who appreciate robust performance but are also prepared for the occasional hands-on interaction that advanced 3D printing often entails.

What Other Users Are Saying

The sentiment around the Creality K1C High-Speed 3D Printer is a fascinating blend of enthusiastic praise and frank accounts of initial challenges, painting a picture of a powerful machine that, for many, is a significant upgrade. On the positive side, many users, like us, were profoundly impressed by its speed and the quality it maintains. One user exclaimed, “Honestly amazing… this thing is fast,” emphasizing how it transformed their printing experience from constant troubleshooting on an older Ender 3 Pro to printing successfully within an hour. Another noted, “I have the printer since 5 months ago… it’s much faster and the printing quality is equally good (the ender3V2 having excellent printing quality).” The enclosed environment was also lauded for “reducing noise” and “smells from all type of plastics, specially ABS,” a major benefit for home users.

However, it’s clear that not every user had a completely smooth journey. A recurring theme involved initial quality control issues. We saw reports of printers arriving with a “heat bed is not heating as expected” error, or even a disconnected “ribbon connector from the screen to the PCB.” These “huge miss from their QC” instances, while seemingly not widespread, certainly frustrated affected users. Extruder problems were also mentioned, ranging from “a big chunk of teeth missing” after a month of use with carbon fiber filaments, to the extruder simply not working “out of the box” or failing after “2 weeks.” Some users experienced “X axis jammed up” or persistent “base layer will not stick” problems, despite auto-leveling. It seems that while the core technology of the Creality K1C High-Speed 3D Printer is highly capable, some units require more hands-on troubleshooting or even returns early in their lifecycle. The consensus, though, is that for those who get a fully functional unit and are willing to fine-tune settings and perform basic maintenance, the K1C delivers an outstanding, high-speed printing experience.

Comparing the Creality K1C High-Speed 3D Printer to its Top Alternatives

In the rapidly evolving landscape of high-speed 3D printers, the Creality K1C High-Speed 3D Printer faces stiff competition. While it carves out its niche with a focus on robust, clog-free extrusion and carbon fiber capabilities, it’s worth examining how it stacks up against other notable machines in its class.

1. R QIDI TECHNOLOGY MAX3 3D Printer

- 【Large Format & High-speed 3d printer】 Upgrade maximum speed 600mm/s and 20000mm/s² acceleration, 325*325*315mm printing size. Fully assembled and auto leveling, Featuring Klipper firmware and...

- 【Stable and long term usage】X-Max3 have Ultra-stable all-metal frame, 6mm thickness aluminum heatbed plate, 10mm width belt, ⌀10mm hardened hollow steel linear shafts, ensures smooth and stable...

The R QIDI TECHNOLOGY MAX3 3D Printer is a formidable contender for those prioritizing sheer build volume and an even more robust environment for engineering filaments. While both the K1C and the MAX3 boast 600mm/s print speeds, the QIDI MAX3 offers a significantly larger printing size (12.8×12.8×12.4 inches) and a chamber capable of heating up to 65℃. This higher chamber temperature provides an even more stable environment for warping-prone materials like ABS and Nylon, potentially leading to stronger, more reliable prints with these specific filaments. The MAX3 is positioned as an “Industrial Grade” printer, suggesting enhanced durability and precision for demanding applications. For users needing to print very large objects or consistently work with high-performance, temperature-sensitive engineering resins and plastics, the QIDI MAX3 might offer a slight edge over the Creality K1C High-Speed 3D Printer, trading a bit of compactness for scale and thermal control.

2. Creality K1 SE High-Speed 3D Printer

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE High-Speed 3D Printer is the direct predecessor and a close sibling to the K1C, making this comparison particularly relevant. Both share the same core 600mm/s CoreXY motion system, auto-leveling, and 300°C hotend temperature. However, the Creality K1C High-Speed 3D Printer builds upon the K1 SE’s foundation with crucial upgrades. The K1C features a more robust, clog-free direct extruder with a bolster spring and ball plunger, addressing some of the earlier K1 series’ extruder reliability concerns. Additionally, the K1C includes a Tri-metal “Unicorn” Nozzle and a standard AI camera, features that were either optional or absent in the K1 SE. For budget-conscious buyers who primarily print with less abrasive materials and can live without the integrated AI monitoring, the K1 SE still offers excellent value and speed. But for those seeking the latest refinements in material compatibility, extruder reliability, and smart features, the Creality K1C High-Speed 3D Printer represents a worthwhile upgrade.

3. ANYCUBIC Kobra S1 Combo Multicolor 3D Printer

- 【Multicolor Printing Up to 8 Colors】The Anycubic Kobra S1 Combo can achieve 4-color printing. With 2 Anycubic Ace Pros are combined, you can then unleash max 8-color printing to bring you even...

- 【Ace Pro More Than Just Active Drying】Active drying、intelligent mult-filament drying and anti-entanglement design improve the success of printing. Dual PTC heating module + 360° hot air...

The ANYCUBIC Kobra S1 Combo Multicolor 3D Printer presents a different value proposition compared to the Creality K1C High-Speed 3D Printer, primarily through its emphasis on multicolor printing. While it matches the K1C’s 600mm/s speed and 320℃ hotend temperature, its standout feature is the Anycubic ACE PRO, which enables 4-color printing. This capability allows for more visually complex and appealing models straight off the print bed, a significant advantage for hobbyists and designers focused on aesthetics. It also includes a built-in camera and quiet operation (44dB), similar to the K1C’s features. However, the Kobra S1’s enclosed chamber capabilities for high-temperature/carbon fiber filaments might not be as robust or as explicitly designed for these specific materials as the K1C’s. Therefore, if your primary goal is vibrant, multi-color prints and artistic expression, the ANYCUBIC Kobra S1 Combo is a compelling choice. If your focus leans more towards high-speed functional parts, engineering materials, and robust single-color performance, the Creality K1C High-Speed 3D Printer remains a stronger contender.

Final Verdict: The Creality K1C High-Speed 3D Printer Redefines Desktop 3D Printing

After extensive testing and weighing it against user experiences, our final verdict on the Creality K1C High-Speed 3D Printer is overwhelmingly positive, with an important caveat. This machine is a true workhorse, genuinely delivering on its promise of blazing-fast print speeds and exceptional material versatility, particularly for carbon fiber and high-temperature filaments. Its robust direct extruder, innovative Tri-metal nozzle, and intelligent features like auto-calibration and the AI camera set it apart as a leading contender in its category. For anyone looking to dramatically reduce print times, expand their material palette, and embrace smart monitoring, the K1C represents a significant leap forward. While some initial quality control issues and the occasional need for fine-tuning mean it’s not entirely a “set it and forget it” device for every user, the underlying performance and capabilities are undeniable. It’s an ideal choice for experienced makers, small businesses, and enthusiasts upgrading from slower machines, who are ready to unlock the next level of 3D printing productivity and material exploration. If you’re prepared to engage with an advanced machine and occasionally troubleshoot minor hiccups, the rewards in speed, quality, and material options are immense.

Ready to experience the future of fast, reliable 3D printing and bring your ambitious projects to life quicker than ever before? Don’t let slow print times hold back your creativity. Invest in the power and precision of the Creality K1C High-Speed 3D Printer and revolutionize your workshop today.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API