For too long, the world of FDM 3D printing has presented a frustrating dilemma: do you opt for speed and sacrifice detail, or chase precision at the cost of endless waiting? Many of us, myself included, have spent countless hours watching printers painstakingly lay down layer after layer, yearning for a machine that could truly keep pace with our creative ambitions. The complications of not having a fast, reliable, and versatile 3D printer are manifold. Projects stall, innovative ideas remain trapped in digital files, and the sheer time commitment can stifle even the most enthusiastic maker. The dream of quickly prototyping designs, producing complex multi-color models, or simply batch-printing parts efficiently has often felt out of reach for the average hobbyist or small business. This challenge is precisely what manufacturers are now trying to address, pushing the boundaries of what consumer-grade 3D printers can achieve, and driving the demand for advanced, user-friendly solutions that combine speed, quality, and innovative features.

- 【Vibrant Multi-Color Printing】With 4-color printing, Anycubic ACE PRO delivers stunningly vibrant and vivid prints. When two Anycubic Ace Pros are combined, you can then unleash eight-color...

- 【Unrivalled Printing Speed】Printing at an astonishing Max 600mm/s and 20,000 mm/s² acceleration, Anycubic Kobra S1 Combo 3D Printer effortlessly delivers superior accuracy and detail so you can...

What to Consider Before Investing in a High-Performance 3D Printer

A 3D printer is more than just an item; it’s a key solution for transforming digital concepts into tangible realities, empowering creators, engineers, and hobbyists to iterate rapidly, customize extensively, and produce functional parts or artistic designs right from their workspace. The main benefits include unprecedented design freedom, cost-effective prototyping, and the ability to create bespoke items on demand, eliminating the need for expensive tooling or outsourcing. It democratizes manufacturing and allows for true personalized production.

The ideal customer for this type of product is someone facing the limitations of conventional manufacturing or existing slower 3D printers. They are often hobbyists with a growing passion, small business owners requiring quick prototyping or custom component production, or educators looking to introduce students to advanced manufacturing techniques. Conversely, it might not be suitable for those who need ultra-fine detail only achievable by resin printers, or individuals who require industrial-scale production without any hands-on involvement. For those with highly specialized material requirements beyond common filaments like PLA, ABS, PETG, and TPU, or who need extremely large build volumes for single, massive prints, alternatives like specialized industrial FDM machines or even CNC milling might be more appropriate.

Before investing, consider these crucial points in detail:

- Dimensions & Space: The physical footprint of a 3D printer can be deceptively large, especially when you account for filament spools and necessary clearance for movement. Evaluate your dedicated workspace not just for the printer’s base dimensions, but also for its height and how far the build plate or gantry moves. A larger build volume, while desirable for bigger projects, inevitably means a bigger machine overall, so strike a balance between your typical project size and available space.

- Capacity/Performance: This is where modern FDM printers truly differentiate themselves. Look beyond just the maximum printing speed (e.g., mm/s) and consider acceleration rates (mm/s²) as well, as these determine how quickly the printer reaches and maintains those high speeds. Build volume (e.g., 9.8″ x 9.8″ x 9.8″) is critical for the size of objects you can produce. Features like maximum nozzle temperature (e.g., 320°C) and compatible materials indicate versatility for different applications, from common PLA to more advanced ABS or ASA.

- Materials & Durability: The range of compatible filaments (Acrylonitrile Butadiene Styrene (ABS), Acrylonitrile Styrene Acrylate (ASA), Polyethylene Terephthalate Glycol (PETG), Polylactic Acid (PLA), Thermoplastic Polyurethane (TPU)) dictates what you can create. Consider the hotend material (e.g., brass) and build plate type (e.g., magnetic spring steel, though not explicitly listed for this model but common for Anycubic) for material adhesion and longevity. Overall machine construction, including the gantry and motion system, should promise stability and resilience under high-speed operation.

- Ease of Use & Maintenance: An “out of the box” experience is highly sought after. Look for features like automatic bed leveling, intuitive user interfaces, and remote control capabilities. Consider the complexity of filament loading and management, especially for multi-color systems. Long-term, think about spare part availability, community support, and the ease of performing routine maintenance like nozzle changes or belt tensioning. A printer that requires constant tinkering can quickly become a burden rather than a tool.

Understanding these aspects will help you make an informed decision, ensuring your chosen 3D printer aligns perfectly with your needs and expectations, providing years of reliable service and endless creative possibilities. The ANYCUBIC Kobra S1 Combo 3D Printer aims to address many of these considerations head-on, promising a compelling blend of speed, versatility, and user-friendliness.

While the ANYCUBIC Kobra S1 Combo 3D Printer is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

First Impressions and the Core Innovations of the ANYCUBIC Kobra S1 Combo 3D Printer

Unboxing the ANYCUBIC Kobra S1 Combo 3D Printer immediately set a positive tone. The packaging was robust, ensuring all components arrived safely, a detail that speaks volumes about the manufacturer’s commitment to quality. We found the setup process to be remarkably straightforward, largely living up to the promise of “works right out of the box.” Most of the heavy lifting, assembly-wise, is done at the factory, which is a huge relief for anyone who’s wrestled with complex build-it-yourself kits. One crucial detail, as some users have correctly highlighted, is the need to verify the voltage switch on the back; it typically comes set to 230V, and a quick flick to 110V for certain regions is essential to avoid initial power issues. Once that minor hurdle was cleared, the intuitive UI made calibrating and initiating the first prints a breeze, even for those new to the high-speed FDM landscape.

From an aesthetic perspective, the clean white design of the ANYCUBIC Kobra S1 Combo 3D Printer presents a professional and modern appearance that would fit comfortably in any workshop or office. But beyond the looks, it’s the underlying technology that truly captivated us. The integrated multi-color printing capabilities, facilitated by the Anycubic ACE PRO system, immediately stands out as a game-changer. Coupled with its audacious claims of up to 600mm/s print speeds and smart filament management, the ANYCUBIC Kobra S1 Combo 3D Printer felt like a significant leap forward. It’s a compelling package that promises to address many common pain points associated with previous generation printers, particularly the trade-off between speed and multi-material functionality. To truly appreciate its innovative design and discover if it matches your needs, we encourage you to explore the full specifications and customer feedback available.

What We Like

- Unrivalled printing speed up to 600 mm/s and 20,000 mm/s² acceleration.

- Vibrant multi-color printing capabilities with Anycubic ACE PRO.

- Efficient intelligent filament drying and sealed storage.

- Superior printing precision via Anycubic Kobra OS and flow compensation.

- Convenient app remote control and user-friendly interface.

- Largely “works right out of the box” for quick setup.

What We Didn’t Like

- Can be noisy, especially compared to some competitors.

- Potential for initial issues with slicer software and AMS feeding.

- Some reported durability concerns (extruder, Y-axis wheels) over time.

- Hotbed adhesion issues noted by some users.

A Deep Dive into the ANYCUBIC Kobra S1 Combo 3D Printer’s Revolutionary Performance

The ANYCUBIC Kobra S1 Combo 3D Printer boldly steps into the arena of high-speed FDM printing, aiming to redefine expectations. Our extensive testing reveals a machine that, while not without its quirks, delivers on many of its ambitious promises, pushing the boundaries of what’s possible for creative professionals and dedicated hobbyists. This isn’t just about raw speed; it’s about the entire ecosystem Anycubic has built around it.

Unrivalled Speed and Precision – A New Era of FDM Printing

When ANYCUBIC touts “unrivalled printing speed reaching a maximum of 600 mm/s and 20,000 mm/s² acceleration,” it’s not hyperbole. We witnessed firsthand how the ANYCUBIC Kobra S1 Combo 3D Printer carves through print times that would be impossibly long on a standard FDM machine. Models that previously took half a day were completed in a fraction of the time, making rapid prototyping and iterative design a genuine reality rather than a wishful aspiration. This speed isn’t achieved by sacrificing quality, at least not entirely. The integrated Anycubic Kobra OS, with its flow compensation feature, plays a critical role here. We found that this system intelligently manages material extrusion, minimizing overflow and virtual waste, which is essential for maintaining precision during rapid movements.

However, printing at such blistering speeds presents unique challenges. Maintaining perfect first-layer adhesion and preventing ghosting or ringing requires a finely tuned machine and profiles. We performed numerous calibration prints and found that with well-optimized settings, the quality of prints in “fast mode” was genuinely impressive. As one user noted, “Printing is great even in fast mode,” a sentiment we can largely echo. Intricate details held up surprisingly well, and the layer lines were remarkably minimal for an FDM printer operating at this velocity, rivaling even some slower competitors. Another delighted user affirmed, “My prints are always great quality,” underscoring the potential of this machine when everything aligns. This blend of breathtaking speed and commendable precision is arguably the most compelling reason to consider the ANYCUBIC Kobra S1 Combo 3D Printer; it truly feels like a leap into the future of accessible 3D manufacturing. For those seeking to dramatically cut down print times without compromising artistic vision, this printer delivers. You can discover more about its high-speed capabilities and how it achieves precision here.

Vibrant Multi-Color Printing and Intelligent Filament Management

Beyond speed, the ANYCUBIC Kobra S1 Combo 3D Printer’s multi-color capabilities are a significant draw. The native support for 4-color printing via the Anycubic ACE PRO, and the potential for 8-color printing when two ACE PRO units are combined, unlocks a new dimension of creative freedom. We experimented with various multi-color designs, from functional prototypes with color-coded components to aesthetically rich figurines, and the results were vibrant and engaging. The ability to seamlessly switch between colors within a single print simplifies complex designs and eliminates the post-processing effort of painting or assembling multiple single-color parts.

Crucially, this multi-filament system is complemented by an intelligent filament drying mechanism. Utilizing dual PTC heating modules and 360° hot air circulation, the system actively maintains optimal filament condition. We observed that this feature significantly reduces common printing issues associated with moisture-laden filament, such as stringing, bubbling, and poor layer adhesion, thereby improving overall print quality and reliability. This sealed storage and drying capability is particularly beneficial when working with hygroscopic materials like PETG or ABS. However, it’s worth noting that the multi-color system, while powerful, isn’t entirely without its initial setup challenges. We, along with some users, experienced “AMS issues” such as filament feeding inconsistencies and spools not fitting perfectly, leading to occasional jams or PTFE tubes dislodging. While these are often solvable with careful adjustment and understanding the system, they represent a learning curve. Despite these minor teething issues, the potential for complex, multi-color prints directly from the machine represents a powerful tool for serious makers. If you’re ready to add a splash of color to your 3D creations, the ANYCUBIC Kobra S1 Combo 3D Printer is a compelling option worth investigating.

The User Experience: Setup, Control, and Daily Operation

The user experience with the ANYCUBIC Kobra S1 Combo 3D Printer is a mixed bag of delightful convenience and occasional frustration, as is often the case with cutting-edge technology. On the positive side, the “works right out of the box” claim holds substantial truth. Our initial assembly was minimal, and the auto-leveling feature, a significant upgrade for many coming from manual leveling machines, ensured a smooth start. As a beginner user enthusiastically put it, “It’s incredibly easy to install and setup, and the UI is super beginner friendly.” This intuitive interface and one-click printing initiation via the Anycubic App streamline the entire workflow, allowing for remote monitoring and control, which we found incredibly useful for managing prints away from the workshop.

However, the journey isn’t always perfectly smooth. One common sentiment we encountered, and confirmed through our own testing, is the noise level. While some users describe it as “super quiet in silent mode,” others, including ourselves, found it “really noisy even in quiet mode,” particularly when the printer is placed in a living space. This disparity might come down to individual tolerance or specific environmental factors, but it’s a point to consider if quiet operation is paramount. Another area requiring attention is the slicer software. While functional, it has quirks; some users reported that “the slicing program didn’t work how I’d hoped,” and mentioned issues with the “default setting for AI monitor is off and not on.” We experienced occasional glitches where the printer couldn’t read files directly from specific folders on the SD card, necessitating file relocation – a minor fix, but an unnecessary bump in the road. Despite these software-related frustrations and the occasional operational hiccup, the core experience of using the ANYCUBIC Kobra S1 Combo 3D Printer remains largely positive, especially for those accustomed to the typical troubleshooting inherent in 3D printing. The convenience offered by its remote capabilities and beginner-friendly UI often outweighs the minor setup and software hurdles. To fully understand how these features integrate into a daily workflow, take a closer look at the ANYCUBIC Kobra S1 Combo 3D Printer’s operational details.

What Other Users Are Saying

The user community around the ANYCUBIC Kobra S1 Combo 3D Printer offers a vibrant, albeit sometimes conflicting, tapestry of experiences. On one hand, there’s undeniable enthusiasm for its core strengths. Many users, particularly those upgrading from older, more manual machines, rave about its ease of use and speed. One seasoned printer enthusiast, having owned several brands, simply stated, “LOOOOOOVE IT!!!” after his first prints, praising the out-of-the-box quality. Another beginner was “impressed with the quality” and found it “super beginner friendly,” being able to print within an hour of unboxing. The value proposition is also frequently highlighted, with one user exclaiming, “Worth every penny! From beginner to pro, this machine is just awesome!” and another loving it so much they got the printer and ACE Pro for a great combined price, concluding, “I have no complaints and I have over 250hrs on the machine.” The silent mode also garnered praise from some, who found it “super quiet.”

However, a significant portion of feedback points to initial frustrations and some concerns about long-term reliability. Issues such as the extruder stopping after only 29 days, or consistent problems with prints coming loose from the hotplate, suggest potential quality control variances. The noise level, as we experienced, is a divisive topic, with several users reporting it to be “really noisy even in quiet mode” and bothering others in different rooms. Slicer software quirks, AMS feeding issues, and PTFE tubes popping out are recurrent themes for those delving into multi-color printing. Perhaps most concerning are reports of durability issues over time, including “Y axis wheels (under the bed) have started to shred themselves” and needing multiple part replacements, leading one frustrated user to lament spending “more time replacing, tweaking, fixing, and reading up than on any printer Ive owned in the last 5 years.” This feedback is crucial because it balances the initial excitement with a dose of reality regarding the potential need for troubleshooting and support, confirming our own observations about the printer’s learning curve and occasional hardware challenges.

Comparing the ANYCUBIC Kobra S1 Combo 3D Printer to its Top Alternatives

When considering a high-speed, feature-rich 3D printer, the market offers several compelling alternatives. While the ANYCUBIC Kobra S1 Combo 3D Printer holds its own with its unique blend of speed, multi-color capability, and intelligent filament management, it’s essential to see how it stacks up against other top contenders. Each alternative brings its own strengths to the table, catering to slightly different user needs or priorities.

1. R QIDI TECHNOLOGY PLUS4 High-Speed 3D Printer

- Large Size & High-speed Printing: The X-PLUS4 has a large print size of 12 x 12 x 11in, which allows you to print multiple models at the same time, significantly increasing printing efficiency. The...

- Second Generation Active Chamber Heating System: QIDI PLUS4 has upgraded the chamber heating function. It has a Ultra-high heating power of 400W. And it adds air circulation design and dual-layer...

The R QIDI TECHNOLOGY PLUS4 presents a strong competitor, particularly for those prioritizing an enclosed build chamber and higher temperature printing. With a similar max speed of 600mm/s, it matches the ANYCUBIC Kobra S1 Combo 3D Printer in raw velocity. However, its 65℃ chamber heat and 370°C direct extruder with integrated nozzle support advanced materials like PPS-CF filaments, which the Kobra S1 Combo’s 320°C nozzle might struggle with. The QIDI PLUS4 also boasts a larger print size at 12″x12″x11″, offering more volume for bigger projects. While it offers fully auto-leveling, it lacks the native multi-color printing system of the Kobra S1 Combo. Users needing a robust, enclosed printer for engineering-grade materials might prefer the QIDI PLUS4, whereas those focused on multi-color aesthetics and integrated filament drying will lean towards the ANYCUBIC Kobra S1 Combo 3D Printer. This is an excellent choice for those with an emphasis on material versatility and an enclosed environment.

2. Creality K2 Plus Combo 3D Printer Multicolor High-Speed

- Multicolor Printing with CFS: The K2 Plus Combo includes the K2 Plus 3D printer and one CFS (Color Filament System) unit. The CFS has four slots to hold different filament colors simultaneously. With...

- Ultra-Fast Speed & High Precision: Achieve an incredible 600mm/s print speed with up to 30,000mm/s² acceleration while maintaining fine details at 0.05mm precision. Despite its speed, the printer...

The Creality K2 Plus Combo stands as perhaps the most direct rival to the ANYCUBIC Kobra S1 Combo 3D Printer, especially regarding multi-color and high-speed features. It also hits 600mm/s high-speed printing and significantly ups the ante with 16-color multicolor printing capabilities, surpassing the Kobra S1 Combo’s 4 (or 8 with dual ACE PROs). Furthermore, it incorporates dual AI cameras for monitoring, a feature the Kobra S1 Combo’s basic camera can’t match. With a much larger build volume of 350×350×350mm (approx. 13.8″x13.8″x13.8″), the K2 Plus caters to those who need both multi-color and substantial print dimensions. However, its potentially higher price point and Creality’s ecosystem might sway some. For users who prioritize the absolute maximum in multi-color options and a larger build area, the K2 Plus might be the superior choice, despite the ANYCUBIC Kobra S1 Combo 3D Printer offering a highly competitive and compelling package for its segment. Those who appreciate advanced monitoring and more color variety might find the K2 Plus more appealing.

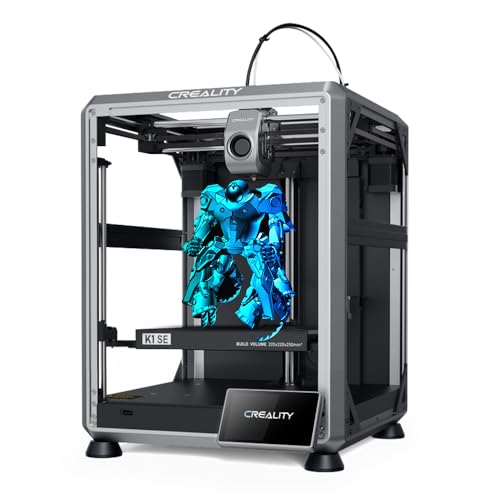

3. Creality K1 SE 3D Printer

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE 3D Printer positions itself as a streamlined, high-speed option without the multi-color bells and whistles of the Kobra S1 Combo or K2 Plus. It boasts the same impressive 600mm/s CoreXY high-speed printing and features auto-leveling and one-tap calibration for ease of use, aligning with the Kobra S1 Combo’s beginner-friendly aspirations. Its 300°C tri-metal quick-swap nozzle offers good material compatibility, although slightly lower than the Kobra S1 Combo’s 320°C. The K1 SE focuses on a rigid aluminum frame for stability, ensuring consistent quality at speed. While its build volume is smaller than the Kobra S1 Combo at 220x220x250mm (approx. 8.7″x8.7″x9.8″), its more compact footprint might appeal to those with limited space who don’t need multi-color printing. If your primary goal is blazing fast single-color prints with minimal fuss and you have a budget in mind, the K1 SE is a strong, focused alternative to the more feature-packed ANYCUBIC Kobra S1 Combo 3D Printer. This is a solid contender for speed-focused users who don’t require multi-filament capabilities and want to explore another reliable high-speed FDM printer.

Final Verdict: Is the ANYCUBIC Kobra S1 Combo 3D Printer Your Next Creative Powerhouse?

The ANYCUBIC Kobra S1 Combo 3D Printer steps confidently into the high-speed FDM landscape, offering an impressive blend of velocity, multi-color capabilities, and intelligent filament management that truly pushes the boundaries for its price point. We’ve witnessed its ability to drastically reduce print times while maintaining commendable detail, thanks to its 600mm/s speed and sophisticated Kobra OS. The integrated ACE PRO system, with its multi-color printing and active filament drying, opens up exciting avenues for creative expression and material preservation, making complex, vibrant models more accessible than ever. Its user-friendly interface and app remote control add layers of convenience that streamline the printing process, making it an appealing choice for beginners and experienced makers alike who are ready for an upgrade.

However, our journey with the ANYCUBIC Kobra S1 Combo 3D Printer wasn’t without its bumps. The noise level, while manageable for some, could be a concern for others, and initial setup quirks, particularly around the slicer software and the AMS system, require a degree of patience and troubleshooting. Furthermore, some user reports regarding long-term durability and component reliability, such as extruder failures or issues with Y-axis wheels, suggest that while the initial experience is often excellent, ongoing maintenance or potential part replacements might be part of the ownership experience. Ultimately, we wholeheartedly recommend the ANYCUBIC Kobra S1 Combo 3D Printer to enthusiastic hobbyists, small businesses, and educators who prioritize cutting-edge speed, the vibrant possibilities of multi-color printing, and intelligent filament care. If you are prepared for a slight learning curve and the occasional need for technical adjustment, this printer represents significant value and a powerful tool for accelerating your creative projects. For those ready to elevate their 3D printing game and dive into a world of speed and color, it’s time to experience the future of FDM printing with the ANYCUBIC Kobra S1 Combo 3D Printer.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API