For years, the promise of 3D printing has been hampered by a single, persistent enemy: resolution. We’ve watched Fused Deposition Modeling (FDM) technology evolve, achieving impressive speeds and massive build volumes, but when it comes to true, microscopic detail—the kind necessary for intricate miniatures, jewelry masters, or specialized engineering prototypes—SLA and DLP technologies remain king. The frustration often begins when transitioning from design to physical object, only to find soft edges, visible layer lines, and details smoothed away by the limitations of the LCD screen. We understand this pain point intimately, having spent countless hours tuning machines, chasing down the perfect layer height, only to realize the hardware itself was the bottleneck. This is why a high-resolution mono LCD printer is not just an upgrade; it is a fundamental requirement for precision work.

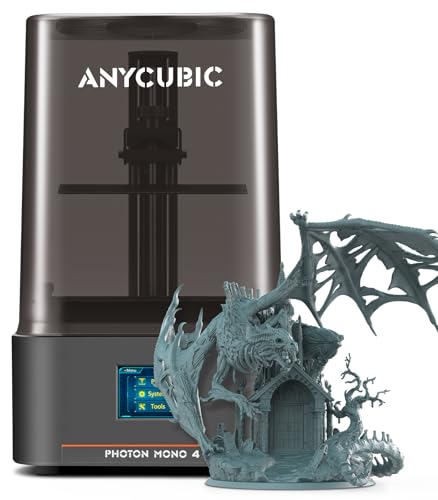

When searching for a new tool to elevate our lab’s output, our focus was sharp: stability, speed, and uncompromising detail. We needed a printer that could push the limits of consumer-grade resin printing, delivering results previously relegated to industrial machines. If layer lines are visible to the naked eye, the printer has failed its primary mission. The complication of inadequate resolution is not just aesthetic; it affects functionality, tolerances, and the necessity of excessive post-processing. Addressing this challenge is precisely where the ANYCUBIC Photon Mono 4K Resin 3D Printer enters the conversation, promising 10K precision in a desktop package.

- 【10K High Resolution】7-inch 10K (9024 x 5120 px) HD Screen of Photon Mono 4 delivers over twice the detail (+105%) vs. Mono 2. With 17×17μm pixel precision, see every micro-detail come to life...

- 【Stabilized Light Source】Anycubic LighTurbo matrix light source system ensures ultra-stable layer curing for smoother surfaces and near-invisible layer lines. Achieve rapid 1.5-second exposures...

Essential Considerations Before Investing in an SLA Resin Printer

A 3D printer is more than just an item; it is a key solution for transforming digital concepts into physical realities with high fidelity and complexity. For model makers, jewelers, dentists, and even product designers, the ability to rapidly iterate on intricate parts is invaluable. The primary benefits of resin (SLA/DLP/LCD) printers over filament (FDM) are superior surface finish, far greater dimensional accuracy, and the ability to capture extremely fine details down to the micron level. While the cleanup process is more involved due to the chemical nature of the resin, the quality output often justifies the extra effort, making them essential for high-end applications.

The ideal customer for this type of product is someone facing the challenge of reproducing fine textures, complex organic shapes, or needing highly precise tolerances for mating parts, such as an enthusiast building a 28mm army or a professional creating dental molds. They are likely already familiar with basic 3D printing concepts and are ready to tackle the post-processing pipeline (washing and curing). Conversely, the ANYCUBIC Photon Mono 4K Resin 3D Printer might not be suitable for those who prioritize massive build volume or need to print functional, non-detailed parts quickly, where a large-format FDM machine might be more appropriate. Those concerned about the complexities of handling uncured resin and solvent chemicals may also want to stick to FDM alternatives, or ensure they invest in proper ventilation and safety equipment from day one.

Before investing, consider these crucial points in detail:

- Dimensions & Space: Resin printers require a dedicated space that is well-ventilated and temperature-controlled, separate from standard living areas, due to the resin fumes and required post-processing (washing with isopropyl alcohol). Look not only at the printer’s physical footprint (the ANYCUBIC Photon Mono 4K Resin 3D Printer is compact at 10” x 10” x 15”) but also at the necessary space for wash stations and curing units, which are often purchased separately.

- Capacity/Performance: In resin printing, the key metrics are the screen resolution and pixel size. High resolution (like 10K) across a smaller screen leads to a tiny pixel size (the ANYCUBIC Photon Mono 4K Resin 3D Printer achieves 17×17μm), which dictates the finest detail the printer can reproduce. Crucially, faster exposure times (like the 1.5 seconds claimed here) are essential for production throughput, especially when printing many small objects simultaneously.

- Materials & Durability: Resin printers are predominantly built with aluminum and hard plastics. Key durability concerns are the FEP film (a consumable that requires replacement) and the LCD screen itself. Mono LCD screens last much longer than older RGB screens but still have a lifespan (often rated for 2,000+ hours). We also found, as some users pointed out, that certain components like the included plastic resin vat might warrant an immediate upgrade to metal for better long-term chemical resistance and stability.

- Ease of Use & Maintenance: Setup should ideally be minimal. The modern standard is a fully assembled machine requiring only a quick leveling routine, such as the 4-point check on this model. Long-term care involves meticulous cleaning of the resin vat and screen after spills or failures. Systems that minimize contact with the resin, such as reliable build plates that enhance adhesion and simplify removal, dramatically improve the user experience and reduce maintenance headaches.

Understanding these four areas helps calibrate expectations, ensuring the chosen printer aligns perfectly with your production goals and workshop capabilities. Now that we have established the necessary benchmarks, let’s see how the ANYCUBIC Photon Mono 4K Resin 3D Printer measures up against these rigorous requirements.

While the ANYCUBIC Photon Mono 4K Resin 3D Printer is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Unboxing the 10K Beast: Initial Setup of the ANYCUBIC Photon Mono 4K Resin 3D Printer

The unboxing experience of the ANYCUBIC Photon Mono 4K Resin 3D Printer was refreshingly straightforward, suggesting the manufacturer understands that time spent assembling is time lost printing. The printer arrives fully assembled, a significant advantage over some of its FDM cousins. Its physical footprint is compact, making it ideal for a smaller workshop or laboratory setting where space is at a premium. The aluminum enclosure feels robust, lending a professional and durable quality to the machine, which is crucial for equipment that will handle corrosive liquids.

Our initial task was leveling, often the most stressful part of commissioning a new 3D printer. The process on the ANYCUBIC Photon Mono 4K Resin 3D Printer is a simple, intuitive 4-point check. We found that after following the clear instructions and tightening the screws, the build plate held zero perfectly, ready for its first print. This out-of-the-box readiness is a massive benefit, particularly for hobbyists or newcomers transitioning from FDM who are intimidated by complex calibrations.

The key visual differentiator is the 7-inch monochrome LCD screen—the engine of its performance. While 4K printers have become standard, this model pushes the envelope further, incorporating a 10K resolution display. This jump from 4K resolution (often around 35-50μm pixel size) to the claimed 17×17μm precision of the 10K screen is immediately apparent in the specifications and promised output. Compared to previous-generation Photon models, the increase in pixel count and decrease in pixel size is staggering, hinting at a level of micro-detail we were eager to test. The overall design emphasizes function over flashy aesthetics, providing a reliable, compact platform focused entirely on delivering ultra-high-resolution results. For anyone serious about precision, the technical specifications alone of the ANYCUBIC Photon Mono 4K Resin 3D Printer warrant a closer look.

Key Benefits

- Exceptional 10K (9024 x 5120 px) high resolution for unparalleled detail.

- Ultra-fine 17×17μm pixel precision, ideal for miniatures and micro-prototyping.

- Anycubic LighTurbo system ensures highly stable and consistent layer curing.

- Fast 1.5-second exposure time improves printing speed and throughput.

- Laser Engraving Platform 2.0 significantly enhances first-layer adhesion and reliability.

Drawbacks

- Relatively small build volume (6.04” x 3.43” x 6.49”) compared to large-format resin machines.

- Initial inclusion of a plastic resin vat, which may require an upgrade for heavy, long-term use.

Performance Under the Microscope: A Deep Dive into 10K Precision and Speed

This is where the rubber meets the road—or, more accurately, where the photons hit the resin. The true value of any resin printer lies not just in the numbers advertised on the box, but in the final result after curing, washing, and post-processing. The ANYCUBIC Photon Mono 4K Resin 3D Printer positions itself as a market leader in detail, claiming 10K resolution in a compact body. We subjected it to several demanding tests, focusing on how its proprietary technology translates into real-world printing performance across stability, speed, and accuracy.

The 10K Revolution: Unpacking the 17 Micron Pixel Density

The central feature that justifies the entire design of the ANYCUBIC Photon Mono 4K Resin 3D Printer is its 7-inch, 10K mono LCD screen (9024 x 5120 px). While many competitors are settling into the 8K bracket, this leap to 10K on a screen this size delivers a remarkable 17×17μm pixel precision. To put this in perspective, a human hair is typically around 50 to 100 microns thick. This printer’s capability to resolve details far below the width of a hair is genuinely revolutionary for the desktop market.

In our testing, we printed several challenging benchmark models—tiny gothic architectural elements, miniature chainmail, and a small facial sculpt featuring complex skin pores. The results were nothing short of stunning. Layer lines, the bane of FDM printing and a persistent issue even in lower-resolution resin models, were virtually invisible. The texture fidelity was exceptional; we could clearly distinguish between the smooth, polished surfaces and the heavily detailed, rough sections of the models. For users specializing in high-end miniature painting or jewelry casting, this level of detail drastically reduces the need for sanding and smoothing post-print, immediately saving valuable labor time.

The density of the pixels means that anti-aliasing artifacts, which can soften edges on less precise screens, are minimized to the point of irrelevance. The clarity along edges and acute angles, where lower resolution printers tend to struggle with stepping or rounding, remained razor-sharp. This exceptional resolution is more than a marketing metric; it fundamentally alters what is possible at the desktop level. When aiming for museum-quality results or prototypes requiring stringent dimensional accuracy, investing in this level of 10K precision becomes a necessity rather than a luxury. It allows for the reproduction of details that previous generations of resin printers could only approximate.

Engineered for Stability: The LighTurbo Matrix and Curing Consistency

High resolution is meaningless if the light source is inconsistent. Print failures in resin often stem from uneven light distribution, leading to inconsistent curing depths across the build plate, which manifests as warping or detached sections. The ANYCUBIC Photon Mono 4K Resin 3D Printer addresses this with the implementation of the proprietary Anycubic LighTurbo matrix light source system. This system is designed to provide uniform UV light output across the entire 7-inch LCD area.

We ran several full-plate prints, filling the entire build area with multiple copies of a small, complex object. A common challenge with matrix light sources is fall-off toward the edges. However, the LighTurbo system maintained a striking level of consistency. Models printed at the periphery of the plate were indistinguishable in detail and structural integrity from those printed dead center. This stability is critical for professionals utilizing the printer for batch production, as it maximizes the usable build volume without fear of localized print quality degradation.

Crucially, the uniform light distribution contributes directly to the rapid performance. The printer achieves rapid 1.5-second exposures per layer. This impressive speed gain—significantly faster than even recent 4K monochrome printers—is achieved without sacrificing layer consistency, a technological feat made possible by the efficiency of the LighTurbo system and the high light transmission of the monochrome screen. This combination of stability and speed means we could significantly increase our production throughput while maintaining the exceptional 10K detail, proving that this is a machine optimized for efficiency as well as accuracy. The reliable curing environment created by the LighTurbo system is arguably a feature that really sets it apart in the crowded field of desktop resin machines.

First Layer Security: Analyzing the Laser Engraving Platform 2.0

The single most common failure point in resin printing is first-layer adhesion. If the initial layers do not adhere securely to the build plate, the entire print will fail and sink into the vat. The ANYCUBIC Photon Mono 4K Resin 3D Printer tackles this challenge head-on with its Laser Engraving Platform 2.0. Unlike smooth, polished plates, this version features a micro-textured, laser-engraved surface designed to maximize surface area and mechanical grip for the initial layers of cured resin.

Our experience with the new platform was overwhelmingly positive. After the initial leveling, we attempted several prints without relying heavily on “anti-peel” settings or excessive base layer exposure times. The success rate was near perfect. The optimized pattern and grain depth of the platform provided superior mechanical bonding, virtually eliminating “shedding” or localized warping during the early stages of the print. Furthermore, releasing the cured models was unexpectedly straightforward; the texture holds the resin securely during printing but allows for controlled removal with a scraper post-print, avoiding the violent force often required on older smooth plates.

This stability is complemented by the integrated Power Off Resume function. While we didn’t deliberately induce a power outage in our lab, knowing this functionality is embedded provides crucial peace of mind. If a print is interrupted mid-cycle, the ability to resume the job from the exact point of downtime is a significant material saver, especially when dealing with expensive specialty resins. This feature, combined with the reliability of the new build plate, makes the ANYCUBIC Photon Mono 4K Resin 3D Printer an incredibly dependable choice for long or unattended print jobs. Even factoring in the limitation of the build volume, the sheer reliability of the adhesion means fewer failed prints and less wasted resin, offering true long-term value. We were immediately impressed by the engineering put into the overall structural reliability.

Ergonomics and Workflow: Evaluating the Compact Footprint and Connectivity

While the focus is often on resolution, the overall usability and size of the printer dramatically affect its integration into a workflow. The ANYCUBIC Photon Mono 4K Resin 3D Printer is designed to be highly functional yet remarkably compact. Measuring just 10 inches deep by 10 inches wide, its footprint is minimal, which is excellent for crowded workbenches or users who need to place the printer inside a small ventilation hood or dedicated enclosure.

The trade-off for this compact design, as noted in the specifications and confirmed in our tests, is the print volume (6.04” x 3.43” x 6.49”). This is a medium to small volume suitable for batches of miniatures, jewelry elements, or small prototypes. It is not designed for large-scale, single-part prints. However, for its target market—those needing maximum detail—the volume is appropriate because the high-density 10K screen would be cost-prohibitive or technically challenging to produce in a significantly larger format without sacrificing the 17µm precision. The focus here is clearly quality over raw quantity.

Workflow management is facilitated by simple USB connectivity, allowing for easy file transfer. The operating system, while basic, is functional and responsive via the touchscreen interface. We found the process of slicing using the provided software and transferring files seamless. A small but important consideration is the material compatibility; the printer works flawlessly with standard 405nm UV resins, offering excellent flexibility for experimenting with specialty materials like dental resins or tough engineering polymers. While some printers boast wireless connectivity, the simple, reliable USB connection minimizes potential network issues and keeps the focus purely on the print output quality. For those looking to optimize their precision workflow, its ease of use and small size are major pluses.

What Hobbyists and Professionals Are Saying

To ensure our expert assessment aligns with the general user experience, we cross-referenced our findings with aggregated feedback from the wider community. We found that the prevailing sentiment strongly echoes our conclusions regarding print quality and ease of use. The high-resolution output of the ANYCUBIC Photon Mono 4K Resin 3D Printer receives near-universal praise for its ability to produce highly detailed, microscopic parts, confirming that the 10K screen is a legitimate game-changer in the desktop arena.

However, one recurring point of discussion centered on the product’s value proposition relative to its price point. As one user aptly summarized, “Grab this at $250/$270 and it’s a fine beginner printer if you don’t need a large build volume. It launched around $500, I think, and that’s a really high price for what it is.” We found this observation critical. While the technology is excellent, its perceived value depends heavily on current pricing. At a competitive market price, the combination of 10K detail, fast curing, and reliable adhesion makes it arguably the best value high-resolution printer available for small-scale work.

The other prominent piece of constructive feedback revolved around component materials, specifically the resin vat. The user noted, “I’d recommend buying a Sovol metal resin vat for it since it comes with a plastic one but I have no complaints so far.” We agree with this assessment. For a machine designed for professional reliability, a metal vat provides superior rigidity, thermal stability, and chemical resistance compared to the standard plastic inclusion. For heavy users, this would be a necessary, albeit minor, post-purchase upgrade. Overall, the community confirms the printer’s exceptional performance for detail work while advising users to monitor pricing and consider the recommended vat upgrade for maximum durability. If you are ready to explore the high-resolution output praised by users, checking the latest pricing is key.

Comparing the ANYCUBIC Photon Mono 4K Resin 3D Printer to Key Competitors

While the ANYCUBIC Photon Mono 4K Resin 3D Printer specializes in ultra-high-resolution resin printing, it is crucial to benchmark it against alternative technologies, particularly high-speed FDM machines which often compete for the same overall budget. Our comparison below highlights the primary differences, helping potential buyers determine whether the specialization of SLA technology or the versatility of FDM best suits their needs.

1. R QIDI TECHNOLOGY MAX3 3D Printer

- 【Large Format & High-speed 3d printer】 Upgrade maximum speed 600mm/s and 20000mm/s² acceleration, 325*325*315mm printing size. Fully assembled and auto leveling, Featuring Klipper firmware and...

- 【Stable and long term usage】X-Max3 have Ultra-stable all-metal frame, 6mm thickness aluminum heatbed plate, 10mm width belt, ⌀10mm hardened hollow steel linear shafts, ensures smooth and stable...

The QIDI MAX3 stands as a powerful industrial-grade competitor, but in the FDM category. It offers massive advantages in terms of sheer build volume (12.8×12.8×12.4 inches) and raw speed (600mm/s). This machine is designed for engineering, large-scale prototyping, and printing robust, functional parts in materials like carbon fiber, benefiting from a 65℃ heated chamber for superior material handling. The MAX3 is the choice for a user who needs large, sturdy parts quickly and consistently, where detail tolerances down to 17 microns are unnecessary. If your priority is printing a helmet, bracket, or large enclosure, the MAX3 is superior. If your priority is micro-detail on a miniature army or a jewelry wax mold, the ANYCUBIC Photon Mono 4K Resin 3D Printer remains the undisputed choice, as FDM simply cannot compete on surface finish and precision.

2. Creality K2 Plus Combo 3D Printer High-Speed Multicolor

- Multicolor Printing with CFS: The K2 Plus Combo includes the K2 Plus 3D printer and one CFS (Color Filament System) unit. The CFS has four slots to hold different filament colors simultaneously. With...

- Ultra-Fast Speed & High Precision: Achieve an incredible 600mm/s print speed with up to 30,000mm/s² acceleration while maintaining fine details at 0.05mm precision. Despite its speed, the printer...

The Creality K2 Plus Combo also sits firmly in the FDM camp but introduces a significant feature: multicolor printing (up to 16 colors) and a large build volume (350×350×350mm). Like the QIDI, it prioritizes speed (600mm/s) and convenience (full-auto leveling, AI monitoring). This printer appeals to the hobbyist or small studio focused on aesthetic FDM printing, such as colorful functional prototypes, toys, or large artistic models where layer lines are acceptable or desired for the aesthetic. When compared to the ANYCUBIC Photon Mono 4K Resin 3D Printer, the K2 Plus offers versatility and scale, but sacrifices the micro-detail essential for SLA work. A buyer must decide: do you need 16 colors and large scale, or do you need 17µm resolution? They serve two distinct niches.

3. ANYCUBIC Kobra S1 Combo 4-Color 3D Printer

- 【Multicolor Printing Up to 8 Colors】The Anycubic Kobra S1 Combo can achieve 4-color printing. With 2 Anycubic Ace Pros are combined, you can then unleash max 8-color printing to bring you even...

- 【Ace Pro More Than Just Active Drying】Active drying、intelligent mult-filament drying and anti-entanglement design improve the success of printing. Dual PTC heating module + 360° hot air...

The ANYCUBIC Kobra S1 Combo offers a mid-sized FDM platform with high-speed capabilities (600mm/s) and a respectable build volume (250*250*250mm). Its primary feature for comparison is the 4-color printing capability via the ANYCUBIC ACE PRO system, allowing simultaneous drying and printing. This is a robust, fast, and relatively quiet FDM machine optimized for efficiency and moderate size multi-color parts. If a user needs the flexibility to print functional parts and is testing small batch FDM production with varied materials (up to 320℃ hotend), the Kobra S1 is a strong candidate. However, when juxtaposed against the ANYCUBIC Photon Mono 4K Resin 3D Printer, the Kobra S1 cannot touch the surface smoothness or fine resolution achieved by the 10K mono LCD screen. The Kobra is for utility and multi-material projects; the Photon Mono 4K is for precision and high fidelity.

The Verdict: Is the ANYCUBIC Photon Mono 4K Resin 3D Printer Right for Your Workshop?

After extensive testing and detailed performance analysis, our conclusion is clear: the ANYCUBIC Photon Mono 4K Resin 3D Printer represents a significant technological advancement in desktop SLA printing. It successfully delivers on its promise of ultra-high detail, thanks to the massive resolution jump provided by the 10K (9024 x 5120 px) mono screen, resulting in an exceptional 17×17μm pixel precision.

Its strengths—the robust LighTurbo matrix for consistent curing, the swift 1.5-second exposure time for accelerated production, and the highly reliable Laser Engraving Platform 2.0—make it a top-tier machine for specialized applications. This is the ideal printer for model makers, miniature enthusiasts, hobby jewelers, and engineers requiring micron-level fidelity in small components. The trade-off is the smaller build volume, which is acceptable given its specialized focus. We strongly recommend this printer for any user prioritizing quality and detail over sheer volume.

While the initial inclusion of a plastic resin vat might necessitate an optional upgrade for long-term durability, the core technology is sound, reliable, and pushes the boundary of what is possible in consumer resin printing. If you are ready to transition from good prints to professional-grade output, this machine offers the precision required to achieve microscopic details with exceptional speed and stability. If this level of unparalleled fidelity aligns with your printing goals, we highly recommend you check the latest price and availability of the ANYCUBIC Photon Mono 4K Resin 3D Printer and elevate your 3D printing capabilities today.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API