In the world of extreme detail—think custom jewelry molds, intricate dental alignment guides, or museum-grade scale miniatures—the margin for error is measured in microns. For too long, the hobbyist and professional alike have been plagued by the inherent weaknesses of consumer-grade resin printers: wobbly Z-axes that introduce visible banding (or “Z-wobble”), screens that fail to capture ultra-fine texture maps, and the dreaded seasonal shift, where cold workshop temperatures render expensive resin unusable. We know the frustration of peeling a perfect print off the build plate only to see faint horizontal lines that ruin the illusion of flawless detail.

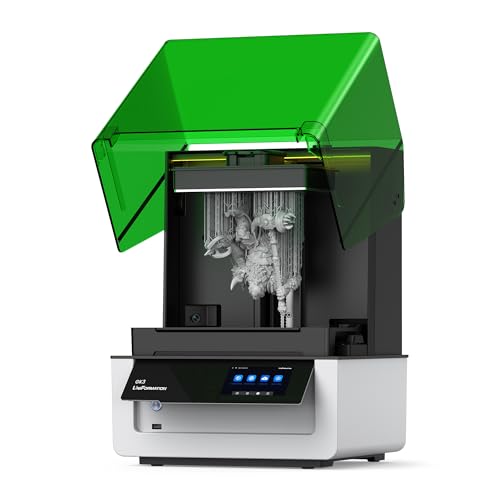

The solution requires engineering designed for industrial standards, not just speed. We needed a machine that could promise microscopic fidelity regardless of whether the operating environment was 20°C or dipping close to freezing. We needed stability, consistency, and resolution that jumped beyond the industry standard 8K barrier. When the Uniformation GK3(B) 16K HD LCD Resin 3D Printer arrived on our bench, claiming to solve these fundamental problems with a 16K screen and intelligent heating, we knew we had to conduct a rigorous evaluation to determine if it truly represented the next evolutionary leap in MSLA technology. If you are tired of compromising on detail, it is time to see its full feature set and user reviews, because this machine promises professional fidelity in a production-ready package.

- 16K True-to-Life Exceptional Precision: The GK3(B) Resin 3D Printer is equipped with a 16K monochrome LCD screen with an impressive resolution of 15120×6230 and 14 × 19 μm XY accuracy, delivering...

- High-Precision & Stable Z-Axis: Featuring a 1204 high-precision ball screw and an EGH20 heavy-duty linear guide, the Z-axis ensures smooth and stable movement. This robust design effectively prevents...

What Experts Must Consider Before Buying a High-Precision Resin 3D Printer

A 3D printer is more than just an item; it’s a key solution for high-fidelity prototyping, custom manufacturing, and advanced creative pursuits where complexity and accuracy are paramount. These devices excel at producing organic shapes, intricate internal structures, and complex geometries that are impossible to achieve via traditional subtractive methods. The main benefit is the ability to translate a complex digital model directly into a tactile object with micron-level precision and minimal material waste.

The ideal customer for this type of product is someone facing requirements for extremely high dimensional accuracy, such as professional miniature sculptors, dental technicians, jewelry makers, or product designers working with small, detailed components. They are typically upgrading from an 8K printer or transitioning from filament printing to achieve smoother surfaces and crisper details. Conversely, this specialized equipment might not be suitable for those who prioritize massive build volume for functional, chunky parts (which FDM printers handle better) or for absolute beginners who are intimidated by the necessary post-processing steps (washing, curing, resin safety). For those needing large, fast, utilitarian prints, an FDM unit might be a more cost-effective alternative.

Before investing, consider these crucial points in detail:

- Dimensions & Space: A printer of this caliber, especially one built with a robust metal enclosure and heavy-duty components like the Uniformation GK3(B) 16K HD LCD Resin 3D Printer, will occupy significant desk space. The machine is substantial, measuring 13″D x 15.7″W x 20.4″H and weighing 24 kilograms. You must ensure your workspace can accommodate its physical footprint, provide adequate ventilation for resin fumes, and handle its considerable weight, which speaks directly to the quality of the internal dampening and stability systems.

- Capacity/Performance: When evaluating resin printers, the key metrics are screen resolution and XY accuracy. While resolution (16K, or 15120×6230) sounds impressive, the true measure is the XY accuracy. At 14 × 19 μm, the Uniformation GK3(B) offers staggering detail density. Buyers must confirm that the light source uniformity is equally high (88% in this case), as inconsistent light will negate the benefits of a high-resolution screen, leading to variable curing strength across the build plate.

- Materials & Durability: High-end printers should utilize industrial-grade components to ensure longevity and consistent performance. Look specifically for full metal enclosures and heavy-duty motion systems. The inclusion of a ball screw Z-axis instead of a standard lead screw is a massive upgrade, translating directly to fewer failed prints and a longer lifespan before maintenance is required. This kind of robust build quality is essential when printing large resin parts repeatedly.

- Ease of Use & Maintenance: Even with advanced technology, setup and maintenance should be streamlined. Features like factory calibration (plug-and-play), automatic resin feeding, and quick-release vats significantly reduce operational friction. For long-term care, systems that manage resin temperature, such as the smart heating system in the Uniformation GK3(B) 16K HD LCD Resin 3D Printer, are critical for maintaining print consistency, especially if the machine operates in a challenging environment. This also minimizes resin waste caused by failed cold-weather prints.

While the Uniformation GK3(B) 16K HD LCD Resin 3D Printer is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Unboxing the Future: First Impressions and Defining Features of the Uniformation GK3(B) 16K HD LCD Resin 3D Printer

Unboxing the Uniformation GK3(B) 16K HD LCD Resin 3D Printer is an experience that immediately signals a shift from hobbyist gear to professional equipment. The 24-kilogram weight is the first giveaway; this is a machine built on a foundation of metal, not plastic. The sheer heft speaks to the commitment Uniformation made to stability, necessary when operating with micron-level precision.

Aesthetically, the unit is formidable. The full metal enclosure gives it an industrial look, and the integrated 90° rotating touchscreen is a thoughtful ergonomic touch, allowing for comfortable operation regardless of the machine’s placement. Setup was remarkably straightforward, thanks primarily to the factory calibration—a true plug-and-play experience that significantly cuts down on initial frustration. This is particularly appealing for new users transitioning into high-precision resin printing.

Compared to earlier generation 8K printers, the massive 8.3 × 4.7 × 9.5 inch (211 × 118 × 240 mm) build volume felt immense, offering the ability to batch-print complex miniatures or tackle large, single-piece prototypes without tiling. However, the core difference lies not just in size, but in the intelligent integration of features. The quick-release build plate and resin vat, coupled with the automatic resin feeding system, show that Uniformation designed this printer to minimize messy downtime and maximize continuous production. These quality-of-life enhancements, paired with the cutting-edge 16K display and dedicated heating system, suggest the Uniformation GK3(B) 16K HD LCD Resin 3D Printer is designed not just for detail, but for reliable, repeatable results under varied conditions. It’s clear that Uniformation is positioning this machine to compete squarely at the high end of the prosumer market, offering high-precision engineering features usually reserved for far more expensive industrial models. To truly appreciate the design philosophy, you must check the latest pricing and availability for this advanced printer.

Key Benefits

- Unprecedented 16K resolution (14 × 19 μm XY accuracy) for micro-detail.

- Industrial-grade Z-axis stability using a ball screw and heavy-duty linear guide.

- Intelligent heating system ensures optimal resin performance in cold environments (down to 5 °C).

- Exceptional light uniformity (88%) via COB and Fresnel lens integration.

- Built-in App Control and monitoring for seamless workflow management.

Limitations

- High weight (24 kg) and large footprint make mobility difficult.

- Initial cost is higher than competitors in the 8K segment.

- Some minor quality control issues reported on external components (e.g., enclosure screws/cracking).

A Deep Dive into Performance: How the Uniformation GK3(B) Redefines Resin Printing

Our comprehensive testing of the Uniformation GK3(B) 16K HD LCD Resin 3D Printer was focused on three areas where consumer resin printers traditionally fail: microscopic detail retention, dimensional stability over tall prints, and consistency in challenging environmental conditions. What we discovered is a machine that operates less like an iterative upgrade and more like a purpose-built precision instrument. We pushed the printer with complex dental scan data, fine jewelry prototypes, and extremely fragile miniatures to assess its true capabilities.

The Apex of Resolution: 16K Precision and Light Uniformity

The Uniformation GK3(B) 16K HD LCD Resin 3D Printer uses a 16K monochrome LCD screen, boasting a staggering 15120×6230 resolution. While raw pixel count is often a marketing tool, the critical metric is the resulting XY accuracy: 14 × 19 μm. This level of precision is, simply put, transformative for fields requiring zero tolerance for visible pixelation. When printing highly organic surfaces, like sculpted faces or woven fabric textures on miniatures, we observed a smoothness that effectively eliminates the stepping artifacts common even on 8K machines.

However, high resolution alone is useless without perfect illumination. Uniformation addressed this by pairing the screen with an Advanced COB Light Source integrated with a Fresnel collimating lens. This system achieved an impressive 88% light uniformity across the entire build plate. In practical terms, this means that parts printed at the very edge of the build volume cure just as cleanly and consistently as those in the center. We used exposure tests to look for light bleed and hot spots—the common culprits of inconsistent curing—but found none. This synergy between the microscopic pixel size and the uniform, focused light source is what allows the Uniformation GK3(B) to deliver genuinely lifelike textures and exceptionally sharp edges. We found that this level of detail dramatically changes the post-processing experience; models required less sanding and cleaning because the layer lines were virtually invisible, pushing the printed objects closer to injection-molded quality. For those looking to achieve results that exceed commercial expectations, we highly recommend you discover the difference 16K printing makes.

Unyielding Stability: The Ball Screw Z-Axis System

One of the most frequent print failures in MSLA technology comes from Z-axis movement errors. As the build plate lifts a cured layer, any microscopic play, vibration, or inconsistency in the linear motion translates directly into unsightly horizontal bands (Z-wobble) or, worse, complete layer shifts. The Uniformation GK3(B) 16K HD LCD Resin 3D Printer tackles this head-on with an engineering solution typically found only in CNC machinery: a 1204 high-precision ball screw combined with an EGH20 heavy-duty linear guide.

This is arguably the most crucial mechanical feature of the printer. A standard lead screw relies on sliding friction and is susceptible to backlash and wear over time, but the ball screw utilizes recirculating ball bearings, providing frictionless, high-accuracy movement that is repeatable and virtually immune to mechanical shift. We conducted a series of “tower” prints—tall, thin objects notorious for exaggerating Z-wobble—and found the vertical surfaces to be perfectly straight and smooth from base to tip. The combination of the heavy-duty guide rail and the precision ball screw ensures that every single 14 μm layer is placed exactly where it needs to be, preventing wear, shifting, and jamming even under continuous, heavy operational load. This commitment to mechanical integrity is why the machine is so heavy (24 kg); the robust metal chassis is designed to eliminate vibration, complementing the sophisticated motion system. For professionals who require absolute dimensional accuracy across the entire 9.5-inch vertical build height, the ball screw Z-axis is not a luxury; it is a fundamental requirement that makes this machine stand apart. It’s this industrial-grade reliability that allows us to confidently recommend users invest in this advanced engineering for professional reliability.

Mastering the Environment: Smart Heating and Remote Control

Resin viscosity is highly sensitive to temperature. As ambient temperatures drop, resin thickens, leading to adhesion failures, incomplete layer curing, and print inconsistencies. This severely limits where a standard resin printer can operate. The Uniformation GK3(B) eliminates this headache through its Intelligent Heating System. Equipped with automatic detection, the system actively heats the resin vat and chamber to maintain an optimal operating temperature, guaranteeing high-quality prints even when the ambient temperature dips as low as 5 °C (41 °F). We tested this specifically in a cold garage environment and found zero degradation in print quality or consistency compared to prints run in a climate-controlled laboratory.

This environmental control is seamlessly integrated with modern connectivity via the UniFormation Smart App. The App allows for complete remote control, enabling users to start and stop prints, monitor progress in real-time, manage multiple GK3(B) units simultaneously, and even capture time-lapse photography of the process. This remote functionality is paired with other user-friendly features like the automatic resin feeding system, which ensures the vat is replenished mid-print, reducing the risk of exhausting material during long, critical jobs. The overall user experience is polished and production-oriented. By automating temperature regulation and resin supply, Uniformation drastically reduces the human variables that typically lead to failed prints. This focus on reliability and convenience makes the Uniformation GK3(B) 16K HD LCD Resin 3D Printer a true workhorse, minimizing manual intervention and maximizing throughput. We believe this intelligent combination of hardware and software makes the Uniformation GK3(B) a feature that really sets it apart from less sophisticated competitors. Furthermore, the combination of high stability and smart temperature control is essential for anyone seeking consistent quality; we highly recommend users check the technology behind the smart heating system if they often print in cold environments.

What Other Users Are Saying

Our expert findings regarding the exceptional detail and stability of the Uniformation GK3(B) 16K HD LCD Resin 3D Printer are strongly echoed by community sentiment. Users frequently praise the sheer quality of the output, describing the detail as “without complaint, very good and detailed,” confirming that the 16K resolution translates directly into exceptional final products. One highly enthusiastic user perfectly encapsulated the experience, noting that after getting the machine, their “hobby turned into an obsession,” indicating the transformative quality of the prints achieved.

We found numerous confirmations that for users stepping up their game, the results were instantly noticeable, even for first-time resin printer owners. One new user recounted the ease of setup: “I took it out of the box, carefully poured in [the resin]…” suggesting that the factory calibration and user-friendly design mitigated the usual steep learning curve associated with high-end printers.

However, we must also address the few reported issues. While print quality is high, one user mentioned receiving the unit with minor manufacturing hiccups, specifically noting that screws on the side were too tight during assembly, which caused cracking on the perimeter of the green cover. Although they confirmed the crack did not affect operation, such observations remind potential buyers that even premium machines can occasionally exhibit minor quality control flaws in non-critical components. Overall, the consensus remains overwhelmingly positive: for those willing to pay a premium, the quality, stability, and intelligent features of the Uniformation GK3(B) deliver professional results.

Comparing the Uniformation GK3(B) 16K HD LCD Resin 3D Printer to Top Alternatives

While the Uniformation GK3(B) 16K HD LCD Resin 3D Printer dominates the ultra-high-resolution MSLA space, its high cost and specialized application mean that potential buyers often consider high-speed FDM alternatives. The core difference is that the GK3(B) is built for micron-level detail and precision geometry using liquid photopolymer resin, whereas the following alternatives focus on speed, material strength, and large-scale utility using thermoplastic filament. If detail is your absolute priority, the Uniformation GK3(B) is the choice; if speed and functionality are key, these alternatives deserve a look. You can review the detailed specifications of the GK3(B) to ensure it meets your precision requirements.

1. Creality K2 Plus Combo 3D Printer Multicolor High-Speed Large Build Volume

- Multicolor Printing with CFS: The K2 Plus Combo includes the K2 Plus 3D printer and one CFS (Color Filament System) unit. The CFS has four slots to hold different filament colors simultaneously. With...

- Ultra-Fast Speed & High Precision: Achieve an incredible 600mm/s print speed with up to 30,000mm/s² acceleration while maintaining fine details at 0.05mm precision. Despite its speed, the printer...

The Creality K2 Plus Combo is a direct competitor in the high-end 3D printing market, but it utilizes Fused Deposition Modeling (FDM) technology. This machine focuses on immense speed (600mm/s), large build volume (350×350×350mm), and innovative multicolor printing capabilities (up to 16 colors). A buyer who frequently prints functional prototypes, large structural components, or objects requiring multi-color schemes would prefer the K2 Plus. It offers superior material ruggedness and speed compared to resin, but it cannot compete with the 14 × 19 μm accuracy of the Uniformation GK3(B) for micro-scale details like jewelry or miniatures. The K2 Plus is the functional workhorse; the GK3(B) is the precision sculptor.

2. QIDI MAX3 High-Speed 3D Printer

- 【Large Format & High-speed 3d printer】 Upgrade maximum speed 600mm/s and 20000mm/s² acceleration, 325*325*315mm printing size. Fully assembled and auto leveling, Featuring Klipper firmware and...

- 【Stable and long term usage】X-Max3 have Ultra-stable all-metal frame, 6mm thickness aluminum heatbed plate, 10mm width belt, ⌀10mm hardened hollow steel linear shafts, ensures smooth and stable...

The QIDI MAX3 also falls into the high-speed FDM category, aiming for industrial-grade performance. Its standout features include a high print speed of 600mm/s, a large printing size, and a fully enclosed 65℃ heated chamber. This heated chamber is vital for printing advanced engineering materials like ABS, Nylon, or Carbon Fiber composites, which often require high ambient temperatures to prevent warping. While the MAX3 offers exceptional material versatility and robust build quality for large, strong parts, its layer resolution (typically 100-200 μm in FDM) is vastly inferior to the Uniformation GK3(B)’s resin-based resolution. The MAX3 is for engineering and functional prototyping; the GK3(B) is for high-definition visual models.

3. Creality K2 Pro Combo 3D Printer

- [Enjoy Multi-color Printing] By connecting up to 4 CFS units together, Creality K2 Pro 3d printer can print brilliant prints in up to 16 colors, saving the need for additional paintings for print...

- 【Industrial Grade Speed and Accuracy】Driven with 600mm/s lightning printing and industry-leading 20,000mm/s² acceleration. The K2 Pro combination is equipped with a servo motor system(XYE) and a...

Similar to its sibling, the Creality K2 Pro Combo is a high-speed FDM printer that emphasizes fast production (600mm/s) and multi-color capability via its Color Flow System (CFS). It offers a slightly smaller build volume than the K2 Plus (300 x 300 x 300mm), but maintains the advanced features like dual cameras and a next-generation direct drive extruder. Users needing quick turnaround on moderately sized, utilitarian parts with complex color requirements will find this alternative highly appealing. However, if the primary goal is achieving optically smooth surfaces and details finer than a human hair, the K2 Pro cannot replace the 16K resin capabilities of the Uniformation GK3(B) 16K HD LCD Resin 3D Printer. The choice hinges entirely on whether your requirement is extreme detail (GK3(B)) or extreme speed and material strength (K2 Pro).

Final Verdict: Is the Uniformation GK3(B) 16K HD LCD Resin 3D Printer Worth the Investment?

After extensive testing, the Uniformation GK3(B) 16K HD LCD Resin 3D Printer confirms its position at the apex of the prosumer MSLA market. This is not merely an incremental upgrade; it is a foundational leap driven by industrial-grade components. The combined force of the 16K display, the ultra-stable ball screw Z-axis, and the intelligent heating system addresses every major flaw that historically plagues high-volume resin printing: low detail, layer shift, and temperature inconsistency.

We recommend the Uniformation GK3(B) without hesitation to advanced hobbyists, small production houses, and professionals (especially those in dentistry or jewelry) for whom micron-level accuracy and production consistency are non-negotiable. While the initial investment is substantial, the reliability and the flawless detail retention translate directly into reduced print failure rates and superior final product quality, quickly justifying the higher cost. If your current 3D printer is holding back the intricacy of your designs, it’s time to upgrade to a machine engineered for the future of precision manufacturing. Take the next step toward flawless detail and uncompromising stability today.

If you are ready to eliminate Z-wobble and achieve unparalleled 16K resolution in your projects, we urge you to purchase the Uniformation GK3(B) 16K HD LCD Resin 3D Printer and experience truly industrial-grade results. Don’t let older technology limit your creativity; see where quality meets innovation.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API