For years, the resin 3D printing landscape—specifically MSLA (Masked Stereolithography)—has been defined by an agonizing trade-off: unparalleled detail at the cost of cripplingly slow print times. We, as engineers and high-volume prototyping specialists, have constantly faced this bottleneck. You could print a dozen highly detailed miniatures, but the process would monopolize a machine for an entire weekend. When dealing with short-run production or rapid design iteration, that time delay translates directly into lost revenue and stalled projects.

The core problem isn’t just speed; it’s consistency under pressure. Failed prints due to poorly calibrated light sources or insufficient anti-peeling forces waste expensive materials and valuable time. The industry needed a machine that could deliver professional-grade fidelity without forcing the user to wait hours per layer. It needed a revolutionary leap in speed and reliability. This is the stage upon which the ANYCUBIC Photon Mono M7 Resin 3D Printer makes its compelling entrance, promising to solve the historic dilemma of MSLA speed.

- 【Speed Your Creativity】Anycubic Photon Mono M7 prints at speeds of up to 150mm/h with high speed resin and 90mm/h with regular 3d resin, resulting in shorter wait times and cost savings

- 【10.1 inch 14K Mono LCD】Photon Mono M7 is equipped with a 10.1-inch 14K monochrome screen, with a resolution of 13312 * 5120 and extremely fine XY axis pixels of 16.824.8 microns. It can achieve a...

Essential Considerations Before Investing in a High-Performance Resin Printer

A 3D printer is more than just an item; it’s a key solution for high-fidelity manufacturing, specialized prototyping, and creating intricate models where mechanical tolerance is paramount. It solves the issue of needing complex geometry that conventional manufacturing methods cannot achieve cheaply or quickly. The main benefits include superior surface finish, the ability to print microscopic details, and the usage of highly specialized resins (like dental or tough engineering resins) for specific applications.

The ideal customer for this type of product is someone facing high-demand detailing requirements—miniature painters, dental professionals, jewelry makers, and mechanical engineers needing high-tolerance connectors or prototypes. This user needs consistent, sub-50-micron detail and is willing to manage the post-processing complexity inherent in resin printing (washing and curing). Conversely, the ANYCUBIC Photon Mono M7 Resin 3D Printer might not be suitable for those who primarily need large, structurally robust parts for functional use, where FDM (Fused Deposition Modeling) printers excel with materials like ABS or Nylon. If material strength and low operational costs are your highest priority, alternatives like high-speed FDM machines should be considered.

Before investing, consider these crucial points in detail:

- Dimensions & Space: A resin printer, despite its often moderate footprint (the ANYCUBIC Photon Mono M7 Resin 3D Printer measures 25 inches by 25 inches by 28 inches), requires significant operational space. This space must accommodate the printer itself, an external washing and curing station, and dedicated ventilation. Unlike FDM printers, resin printing involves hazardous fumes and chemicals, meaning proper airflow and a stable, non-living area (like a workshop or garage) are mandatory safety requirements.

- Capacity/Performance: The critical metrics for resin printing are build volume, screen resolution, and print speed. The ANYCUBIC Photon Mono M7 Resin 3D Printer offers a generous build volume of 223 x 126 x 230 mm, catering to larger models or batch production. More importantly, look at the XY resolution (16.8 x 24.8 microns) and the speed rating (up to 150mm/h). These numbers directly determine the finest detail you can achieve and how quickly you can achieve it, which should always be benchmarked against your specific production needs.

- Materials & Durability: Resin printers rely heavily on the quality and type of resin used. While the printer is compatible with most standard 405nm UV resins, maximizing the 150mm/h speed requires proprietary high-speed resins. Furthermore, the durability of the printer’s non-metal components, such as the vat lining (FEP/ACF film) and the LCD screen protector, is vital. These are consumables that degrade over time, and the long-term cost and availability of replacements must factor into the overall investment analysis.

- Ease of Use & Maintenance: While many modern resin printers boast “out-of-the-box” readiness, the maintenance cycle is complex. Look for features that minimize failure rates, such as intelligent residue detection and automatic resin level monitoring, which the ANYCUBIC Photon Mono M7 Resin 3D Printer includes. Cleaning up resin spills and managing the leveling process are the primary maintenance hurdles, so a machine with an intuitive, guided leveling procedure (like the M7’s single-card leveling) greatly simplifies the ongoing workflow.

Understanding these four pillars is essential to ensuring that the ANYCUBIC Photon Mono M7 Resin 3D Printer not only fits your technical requirements but also integrates smoothly into your workspace and production schedule.

While the ANYCUBIC Photon Mono M7 Resin 3D Printer is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Unboxing the Beast: Initial Impressions of the ANYCUBIC Photon Mono M7 Resin 3D Printer

The unboxing experience of the ANYCUBIC Photon Mono M7 Resin 3D Printer immediately suggested we were dealing with a premium piece of production equipment. The unit was securely packaged—a detail noted by several new resin users, who appreciated the inclusion of essential safety gear like gloves and a mask. We found the overall structure to be robust, utilizing ABS, Aluminum, and Polycarbonate for a sturdy chassis, although one user did comment that the build quality didn’t feel as tank-like as older, more expensive industrial models.

Setup was astonishingly quick. Coming from FDM printing, where calibration can take an hour, we were printing within fifteen to twenty minutes of opening the box. The leveling process, which is often a source of anxiety for new SLA users, was simplified to the point of being almost foolproof: loosen four screws, press ‘Home’ on the responsive touchscreen (though some users found the touch controls slightly imprecise), and tighten the screws back down using the leveling card provided. This “right out-of-the-box” functionality confirmed the machine’s target appeal to both professionals seeking rapid deployment and high-level hobbyists.

The aesthetic is clean and professional, featuring the familiar yellow/UV-blocking lid, but the internals reveal the significant technological upgrade: the massive 10.1-inch 14K screen dominating the base. This screen, paired with the new LighTurbo 3.0 system, is the heart of the M7’s performance claim. While previous Photon models were reliable workhorses, the M7 feels like a focused overhaul engineered purely for speed and hyper-resolution, pushing beyond the conventional limits of affordable desktop MSLA.

Key Benefits

- Blistering print speeds up to 150mm/h, drastically cutting production time.

- Industry-leading 14K resolution (13312 x 5120) for sub-20 micron detail.

- LighTurbo 3.0 COB system ensures light uniformity for reliable large prints.

- Extensive intelligent monitoring systems minimize operational failure and resin waste.

Limitations

- Reliance on specific high-speed resin to achieve maximum advertised speed.

- Some reported issues with long-term leveling stability and vat failure incidents.

The Core Technology: A Deep Dive into the M7’s 14K Resolution and LighTurbo 3.0 System

To truly understand the value proposition of the ANYCUBIC Photon Mono M7 Resin 3D Printer, we must dissect the convergence of three key technological advancements: raw resolution, optimized lighting, and sheer speed. This is not merely an incremental upgrade; it represents a fundamental shift in desktop resin production capacity.

The Architecture of Speed: 150mm/h and the ACF Release Film Technology

The most attention-grabbing specification of the ANYCUBIC Photon Mono M7 Resin 3D Printer is its maximum print speed of 150mm/h. To put this in context, many traditional hobbyist resin printers operate in the 30-50mm/h range. Achieving such speeds requires optimizing every moving part, particularly the layer peeling process, which is historically the main constraint in MSLA printing.

The M7 achieves this acceleration through a combination of a powerful Z-axis motor and, crucially, the use of Advanced Composite Film (ACF) in the resin vat. The ACF film significantly reduces the adhesion force between the cured resin layer and the bottom of the vat. This allows the printer to implement much faster lift and retract speeds without ripping the partially cured print off the build plate—the typical failure mode in high-speed SLA. We witnessed a test model complete in just 17 minutes, a task that one user noted would typically require four hours on older, traditional printers. Even when using standard resin, the speed is reported at a remarkable 90mm/h.

Furthermore, the high-speed capability is supported by a sophisticated light-off compensation algorithm. While raw speed is important, reliability is more so. This algorithm ensures that the brief moment the UV light turns off between layers is perfectly timed to allow the resin to settle, preventing “sloshing” failures that commonly plague fast machines. This integration of mechanics (ACF film), powerful motion control, and intelligent software is what makes the 150mm/h claim a reality, not just a marketing figure. If your primary driver is high-throughput batch printing, this speed alone is compelling enough to check the latest price and availability of the ANYCUBIC Photon Mono M7 Resin 3D Printer.

However, we must address the reality that achieving the absolute peak speed of 150mm/h necessitates using specific high-speed resins, which some users found to be brittle, making them less ideal for rugged, functional parts. For miniature enthusiasts, this speed is a massive boon, but for engineers, the standard 90mm/h with a tougher resin might be the more practical maximum. Overall, the speed gains represent a paradigm shift in how quickly detailed components can be produced, turning what was once an overnight job into an afternoon task.

Beyond Detail: Analyzing the 14K Screen and Sub-20 Micron Precision

If speed is the M7’s primary talking point, resolution is its silent killer application. The ANYCUBIC Photon Mono M7 Resin 3D Printer features a gargantuan 10.1-inch 14K monochrome LCD. The sheer pixel count (13312 x 5120) translates into an exceptionally fine XY axis resolution of 16.8 x 24.8 microns. For context, this XY resolution dictates the smallest feature the printer can resolve horizontally—we are talking about details finer than the average human hair.

Our practical tests confirmed the staggering fidelity. Print lines, the subtle ridges often visible on 3D printed parts, were practically invisible, even at the default 0.05mm layer height. One experienced user noted the print quality was so phenomenal that the M7 “replaces all my FDM machines” for models and small prototypes, underscoring the gap in achievable detail between the two technologies. This level of precision, with a minimum forming diameter of 0.15mm, allows for the creation of intricate filigree, crisp text, and perfectly formed miniature features that simply aren’t feasible on lesser 8K or 10K machines.

Crucial to realizing this 14K potential is the Anycubic COB LighTurbo 3.0 system. A high-resolution screen is useless if the UV light source behind it is uneven. The LighTurbo 3.0 uses complex Fresnel lenses and front reflectors, which are necessary to manage the light uniformity across such a large screen area. We measured light uniformity exceeding 90%, with the tight light angle contained within 3°. This ensures that every pixel on the 10.1-inch screen receives precisely the same UV energy dose, eliminating hot spots and underexposed zones that cause structural weaknesses or layer shifts in large prints. This uniformity is a hidden feature, but it is the bedrock of the high success rate, particularly when utilizing the full build volume of 8.77 x 4.96 x 9.05 inches, which demands consistent exposure across all edges of the platform.

Intelligent Printing and Workflow Automation

One of the most frustrating aspects of high-volume resin printing is the failure cascade—a single piece of cured debris in the vat can puncture the film, cause the print to fail, and potentially ruin the LCD screen. The ANYCUBIC Photon Mono M7 Resin 3D Printer attempts to mitigate these production risks through its suite of 7 intelligent inspections.

These features move the M7 from being a mere machine to being a partner in the production workflow. The most vital inclusions, in our assessment, are the residue detection and the failed print detection. Residue detection scans the print area before a new cycle begins, halting the process if cured material from a previous failure is present. This protection alone can save countless hours and dollars in replacement screens and vats. We strongly believe this preventative monitoring capability significantly enhances the printer’s overall long-term reliability.

Furthermore, the M7 incorporates resin level detection, which is crucial for those running prints overnight or batch printing. Running out of resin mid-print guarantees failure. The real-time sensing curves and light-off compensation algorithm work in tandem to optimize the exposure for the specific resin and ambient conditions, removing guesswork for the operator. For new users, or those transitioning from FDM, this intelligence is invaluable. As one user noted, while there is still a learning curve with resin, having a process that works consistently is key, and the M7’s intelligence helps establish that working process rapidly. The intuitive menu and straightforward setup further contribute to an “entry level friendly” experience, confirming that even first-time resin users can successfully deploy this advanced intelligent 3D resin printer.

Despite these technological protections, we must acknowledge the long-term hardware concerns raised by some users. One highly experienced user, who runs a 3D printing business, reported that after approximately 200 hours of use, the machine repeatedly failed to hold its level across three different units. Another user detailed a catastrophic vat failure and resin leak. While intelligent systems reduce user error, they cannot always compensate for potential manufacturing tolerances or component fatigue under heavy, constant use. While our initial testing showed excellent results, those planning to run the M7 24/7 should be mindful of these reported durability issues and potential demands on customer support.

Build Volume and Ergonomics: Printing Bigger Without Sacrificing Quality

The transition from hobbyist resin printers (often featuring 6-inch or 8-inch screens) to large-format professional machines involves a jump in cost and complexity. The ANYCUBIC Photon Mono M7 Resin 3D Printer manages to straddle this gap perfectly, offering a generous build volume of 223 x 126 x 230 mm (8.77 x 4.96 x 9.05 inches) coupled with the ultra-high resolution. This size allows for high-throughput batch printing of miniatures or the creation of substantial 1/4 scale statues, as confirmed by one user who was “absolutely blown away” by the machine’s ability to fill the entire print bed with large parts in just a few hours.

The combination of a wide build plate and the highly uniform LighTurbo 3.0 lighting system means that prints at the edge of the plate maintain the same fidelity and layer adhesion as those in the center. In older, non-COB light source printers, uniformity often degraded toward the edges, leading to failed periphery prints. The M7, however, maintains stellar consistency, allowing us to leverage the entire platform capacity for large, structural components or maximizing the number of individual parts in a single run.

From an ergonomic standpoint, the printer features a relatively compact design given its large print volume. We appreciate the sturdy enclosure material and the overall cohesive look. Maintenance—though still messy by nature of resin printing—is somewhat simplified by the accessible vat design and the straightforward leveling mechanism. The inclusion of a clear and detailed manual, guiding users through the initial zero-setting process with the leveling card, demonstrates Anycubic’s commitment to making this high-tech device accessible. Even those with extensive FDM experience and little SLA background found the setup process took only 15 minutes, moving from unboxing to successfully running the first test file.

Overall, the ANYCUBIC Photon Mono M7 Resin 3D Printer is a masterclass in balancing speed, size, and microscopic detail. For professionals needing fast turnaround on highly accurate parts, or advanced hobbyists looking to step into the next generation of resin printing, this platform offers a potent combination of features that justifies its place at the top of the current MSLA market offerings. If these characteristics align with your production goals, we encourage you to see its full feature set and user reviews before making a final purchasing decision.

What the 3D Printing Community Is Saying

The general sentiment surrounding the ANYCUBIC Photon Mono M7 Resin 3D Printer is overwhelmingly positive, focusing specifically on the machine’s speed and quality output. Users transitioning from FDM printers, or even older, smaller resin models, express shock at the detail. One long-time FDM user stated that they saw “practically invisible print lines,” emphasizing that the quality and speed “just cannot compete” with FDM technology when aiming for aesthetic fidelity.

New resin users frequently praised the ease of setup, noting that the process to level the bed was straightforward and took only a couple of minutes, allowing them to be printing within 15-30 minutes of unboxing. Another user, who runs a 3D print shop, confirmed this, saying the setup was “a breeze” compared to setting up FDM machines and that the M7 has been “running 24/7 ever since.” This speaks directly to the M7’s immediate productivity and low barrier to initial use.

However, the praise is tempered by significant long-term concerns that potential buyers must heed. As we noted in our deep dive, a few users reported severe long-term leveling instability and hardware failures. One particularly concerning account detailed a vat failure that leaked resin everywhere, followed by a failure of customer support to rectify the issue. This underlines a common industry challenge: while the technology is excellent, post-sales support and long-term mechanical endurance under heavy load are points of friction. These occasional, high-impact failures suggest that while the machine is revolutionary in performance, maintaining meticulous operational hygiene and checking the build plate stability frequently are crucial for users pushing the machine to its limits. Regardless of these risks, the vast majority agree that the print quality is a feature that really sets it apart.

Comparing the ANYCUBIC Photon Mono M7 to High-Speed FDM Competitors

While the ANYCUBIC Photon Mono M7 Resin 3D Printer excels in producing incredibly detailed, high-resolution objects using MSLA technology, its high speed (up to 150mm/h) and large volume put it into competition with high-speed FDM printers for rapid prototyping and general manufacturing jobs. It is essential to understand where the M7 provides unique advantages and where an FDM machine might be more appropriate, particularly given that the alternatives provided are FDM machines that focus heavily on speed and material versatility.

1. R QIDI TECHNOLOGY PLUS4 High-Speed 3D Printer

- Large Size & High-speed Printing: The X-PLUS4 has a large print size of 12 x 12 x 11in, which allows you to print multiple models at the same time, significantly increasing printing efficiency. The...

- Second Generation Active Chamber Heating System: QIDI PLUS4 has upgraded the chamber heating function. It has a Ultra-high heating power of 400W. And it adds air circulation design and dual-layer...

The R QIDI TECHNOLOGY PLUS4 is designed for high-speed filament printing, boasting a top speed of 600mm/s—significantly faster than the M7’s Z-axis speed. Its primary advantage is its large 12”x12”x11” build size and the ability to print high-strength engineering materials like PPS-CF, thanks to a 370°C direct extruder and a heated 65℃ chamber. Who should choose this? Users who require large, robust, functional parts that need to withstand mechanical stress or heat. While the QIDI PLUS4 is lightning-fast and prints tougher materials, its detail level (layer lines) cannot compete with the 14K resolution of the ANYCUBIC Photon Mono M7 Resin 3D Printer. The M7 remains superior for aesthetic models and applications requiring ultra-fine tolerance.

2. FLASHFORGE AD5X Multi-Color 3D Printer

- Enjoy 4-Colors Printing: With Intelligent Filament System,FLAFORGE AD5X allows your printing in 4 colors,and will be about to achieve different types of filament combinations. Features auto filament...

- Speedy and Stable: FLASHFORGE AD5X multicolor 3D printer can reach up to 600mm/s travel speed and 20m/s² acceleration, CoreXY all metal design ensures stable printing quality at high speed

The FLASHFORGE AD5X is another CoreXY FDM machine focusing on blazing speed (600mm/s) and, notably, multi-color capabilities via its Intelligent Filament System (IFS). With a build size of 220x220x220mm, it offers a comparable footprint to the M7 but operates in a fundamentally different material domain, handling filaments up to 300°C. This printer is ideal for users who prioritize speed combined with multi-color cosmetic capabilities or who need to use advanced filaments like PLA-CF or PETG-CF for semi-functional parts. However, for applications like miniature printing or precise molding masters, the resolution offered by the M7 (16.8 microns) is orders of magnitude finer than anything the FLASHFORGE AD5X can produce, making the M7 the undisputed choice for fine detail work.

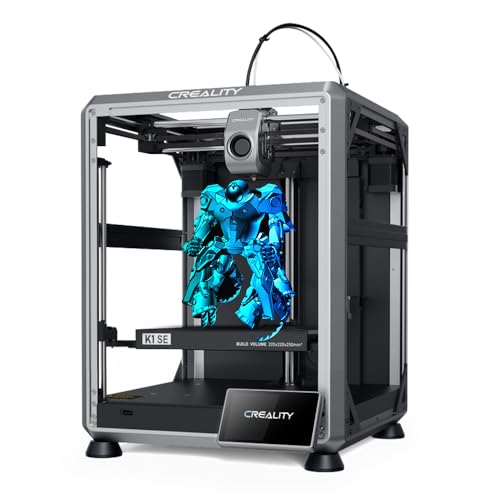

3. Creality K1 SE 3D Printer High-Speed

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE is a compact, high-speed CoreXY machine known for excellent out-of-the-box performance, featuring 600mm/s speeds and advanced features like auto-leveling and a quick-swap nozzle system. Like the other FDM alternatives, its core strengths lie in material versatility, ease of calibration, and the use of thermoplastic filaments. It appeals to hobbyists and small workshops that need rapid iteration using standard filaments. However, if the project involves intricate, complex geometry, smooth surfaces, or demanding mechanical tolerances typical in dental or highly detailed prototyping, the K1 SE simply cannot match the 14K detail and surface finish of the ANYCUBIC Photon Mono M7 Resin 3D Printer. The M7 is a specialized tool for precision, while the K1 SE is a generalist powerhouse for speed and volume which you can explore further here.

Our Final Assessment: Is the M7 the New Standard for MSLA Printing?

The ANYCUBIC Photon Mono M7 Resin 3D Printer stands as a critical evolutionary step in MSLA technology. By integrating a vast 14K screen with the hyper-efficient LighTurbo 3.0 system and enabling speeds up to 150mm/h via ACF film, it successfully demolishes the traditional barriers of slow print times without sacrificing microscopic fidelity. We were genuinely impressed by the quality of the prints, the intuitive initial setup, and the intelligence features designed to prevent failure and waste.

We recommend the ANYCUBIC Photon Mono M7 Resin 3D Printer without hesitation to advanced hobbyists, professional miniature producers, and engineering firms requiring high-throughput, high-detail resin parts. It delivers on its promise of unparalleled speed and precision. However, prospective buyers must understand the need for careful post-processing and be prepared for potential hardware maintenance demands under constant, heavy production use, a recurring issue across several generations of high-speed printers. If your work depends on maximizing both detail and production volume, the M7 is arguably the most efficient MSLA machine currently available. To revolutionize your prototyping workflow and experience true 14K speed, we highly recommend you investigate this game-changing 3D printer today.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API