There’s a unique kind of agony that every 3D printing enthusiast knows well. It’s the feeling of starting an exciting 18-hour print, only to check on it periodically, watching the progress bar crawl forward at a glacial pace. I remember designing a complex prototype part for a project, a piece I needed *that day*. My trusty old printer, a workhorse in its own right, estimated a 22-hour print time. The waiting was excruciating, a bottleneck that stifled creativity and momentum. This is the core problem that high-speed printers promise to solve: to break the chains of slow iteration and turn ideas into tangible objects in a fraction of the time. The leap from a standard 50-60mm/s printer to a machine capable of 600mm/s isn’t just an upgrade; it’s a paradigm shift in how we approach making.

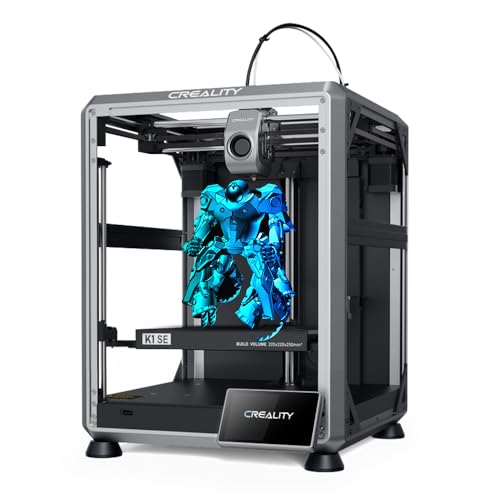

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

What to Consider Before Buying a High-Speed 3D Printer

A 3D Printer is more than just an item; it’s a key solution for creators, engineers, hobbyists, and educators. It transforms digital blueprints into physical reality, enabling rapid prototyping, custom part creation, artistic expression, and hands-on learning. The main benefit of a high-speed model like the Creality K1 SE 3D Printer High-Speed is its ability to dramatically reduce the time between concept and creation. This means more iterations, more experiments, and more productivity. Instead of one large print per day, you could potentially complete five or six, fundamentally changing your workflow and creative output.

The ideal customer for this type of product is someone who has some familiarity with 3D printing and is looking to upgrade from a slower, entry-level machine. They value speed and efficiency and are willing to engage with a more advanced system. It’s perfect for prototypers, small business owners producing custom goods, and serious hobbyists building large-scale projects like cosplay armor. However, it might not be suitable for those who are absolute beginners and expect a completely flawless, appliance-like experience without any learning curve. Some user reports indicate that quality control can be inconsistent, meaning you might need to troubleshoot out of the box. For those seeking ultra-fine detail for things like jewelry or tabletop miniatures, a resin printer might be a more suitable alternative.

Before investing, consider these crucial points in detail:

- Dimensions & Space: The advertised dimensions of 9.9″ x 9.9″ x 9.9″ refer to the build volume. The actual machine footprint is larger. Ensure you have a stable, level surface with adequate clearance for ventilation and access, especially given the vibrations that can occur at high speeds.

- Capacity/Performance: The headline specs are a 600mm/s print speed and 20000mm/s² acceleration. While impressive, these are maximums. Real-world print speeds for quality results will often be lower, but still significantly faster than traditional printers. The CoreXY motion system is key to achieving this speed while maintaining stability.

- Materials & Durability: The rigid, die-cast aluminum frame is essential for minimizing wobble and ensuring accuracy during rapid movements. The all-metal construction is a significant plus for longevity. The ability to handle materials like ABS, PETG, TPU, and even carbon fiber composites, thanks to the 300°C hotend, makes this a very versatile machine.

- Ease of Use & Maintenance: Features like “one-tap” auto-leveling are designed to simplify the most frustrating part of 3D printing. However, long-term care involves keeping guide rails clean, checking belt tension, and occasionally replacing nozzles. The quick-swap nozzle design on this model is a thoughtful feature that simplifies maintenance.

Ultimately, a high-speed printer is an investment in your time. If you find yourself constantly waiting on your current printer, this category of machine is worth serious consideration.

While the Creality K1 SE 3D Printer High-Speed is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Unboxing the Need for Speed: First Impressions and Key Features

Pulling the Creality K1 SE 3D Printer High-Speed from its packaging, the first thing we noticed was its solid, purposeful build. Unlike many kits that feel like a collection of disparate parts, this machine arrives mostly assembled. The die-cast aluminum frame feels incredibly rigid, a crucial requirement for a printer that moves its print head at such high velocities. Assembly was straightforward, taking us just under an hour, a process echoed by many users who found it easy to put together. It primarily involves attaching the gantry to the base and plugging in a few clearly labeled connectors. Aesthetically, it’s a clean, enclosed design that looks more like a serious piece of equipment than a hobbyist’s Erector set. When you place it next to a traditional open-frame “bed slinger” printer, the difference in design philosophy is stark. The K1 SE is built for speed and stability from the ground up, and that’s apparent before you even turn it on. The inclusion of features like a direct drive extruder and a tri-metal, quick-swap nozzle right out of the box makes it feel like a premium offering, and you can see its full feature set and user reviews to get a sense of the value proposition.

What We Like

- Blazing fast 600mm/s print speed dramatically cuts down on project time.

- Rigid CoreXY aluminum frame provides excellent stability for high-speed accuracy.

- High-temperature (300°C) direct drive extruder handles a wide variety of filaments, including flexibles and composites.

- Largely pre-assembled for a quick and relatively easy setup process.

What We Didn’t Like

- Inconsistent quality control can lead to out-of-the-box defects (e.g., Z-axis issues, faulty connectors).

- “One-Tap Calibration” can be misleading; some users report significant manual adjustments are still needed for a perfect first layer.

Performance Deep Dive: Can the Creality K1 SE Handle the Velocity?

A printer can have all the features in the world, but performance is where the plastic meets the build plate. We put the Creality K1 SE 3D Printer High-Speed through its paces, testing its core promises of speed, quality, and user-friendliness. We pushed it with a variety of models, from the classic Benchy benchmark to large, complex cosplay parts and functional engineering prototypes. The results were, for the most part, deeply impressive, but not without some important asterisks that potential buyers need to understand.

CoreXY Speed and Structural Integrity

The headline feature is, without a doubt, the speed. The CoreXY motion system, where the print head moves in the X and Y axes via a clever belt system while the bed only moves down in the Z-axis, is inherently superior for high-speed printing. Unlike bed slingers where the entire print mass is thrown back and forth, the K1 SE keeps the print relatively stationary, allowing for much higher acceleration (up to 20000mm/s²) and top speeds. During our tests, we printed a standard Benchy in under 20 minutes, a feat that would take over an hour and a half on a conventional printer. The quality was remarkably good, with minimal ringing or ghosting artifacts, a testament to the rigid die-cast aluminum frame. This echoes the experience of one user who noted their machine “has been running almost nonstop and hasn’t missed a beat on a single print!” The solid frame does an admirable job of damping the violent vibrations that come with such rapid direction changes. For large prints, this is a game-changer. A helmet that once would have been a two-day commitment can now be completed overnight. However, it’s important to note that achieving the absolute top speed of 600mm/s is best reserved for infill; for high-quality outer walls, we found dialing it back to the 250-300mm/s range provided the best balance of speed and surface finish. This is still a massive improvement and a core reason to consider this high-speed model.

Advanced Extrusion for Material Mastery

Speed is useless if you can’t reliably put down plastic. The upgraded direct drive extruder on the Creality K1 SE 3D Printer High-Speed is a standout component. Its proximity to the hotend provides precise control over filament retraction and extrusion, which is critical for minimizing stringing at high speeds and essential for printing flexible materials like TPU. We tested it with a roll of TPU, and the reinforced tensioner system with its side spring and ball plunger fed the notoriously tricky filament without a single jam. This opens up a whole world of possibilities for printing flexible phone cases, gaskets, and other functional parts. The hotend itself is another star. The ceramic heating element gets the nozzle up to 200°C in well under a minute, and its maximum temperature of 300°C means it’s fully capable of handling engineering-grade materials like ABS, PETG, and even carbon fiber-filled filaments. The “Tri-Metal” nozzle, with its durable steel tip, conductive copper body, and titanium alloy heatbreak, is designed for both high performance and longevity. We found it held temperature consistently, which is crucial for layer adhesion and overall print strength. This material versatility is a huge advantage, turning the printer from a simple PLA toy-maker into a legitimate prototyping and small-scale manufacturing tool.

The Reality of “One-Tap” Auto Calibration

Here’s where the experience can diverge. The promise of “one-click auto-leveling and Z-offset calibration” is alluring, as getting a perfect first layer is the foundation of any successful print. When it works, it’s fantastic. The system uses strain gauges in the print head to tap the bed in multiple locations, creating a mesh that compensates for any minor warps or tilts. On our test unit, the initial calibration worked flawlessly, and our first prints stuck perfectly to the build surface. However, we cannot ignore the significant number of user reports describing a frustrating out-of-box experience. Several users found that “even with the bed springs fully compressed the nozzel wanted to push down into the glass bed.” This indicates a Z-stop switch that is positioned incorrectly, a clear quality control failure. One resourceful user had to attach “a piece of cardboard to the frame above the z axis stop switch so the z axis stays higher” just to get it working. While this is a fixable problem, it’s not something a new user should have to diagnose. This suggests that while the underlying technology is sound, the execution on the assembly line can be hit-or-miss. Potential buyers should be prepared for the possibility that their “one-tap” process might involve some manual tweaking and online research. It’s a solvable problem, but it detracts from the “plug and play” experience advertised. The performance when dialed in is excellent, but getting there might take more effort than expected, a crucial detail to know before you check the latest price and availability.

What Other Users Are Saying

Scouring feedback from the community reveals a tale of two printers. On one hand, many users are thrilled, calling it truly “plug and play.” One user, whose 13-year-old son assembled it, reported that after a single false start, “all the following prints went flawlessly.” Another highly recommends it, stating, “I had this assembled in an hour and a half. I was printing 30 minutes after that. I have had great bed adhesion the entire time.” These reviews paint a picture of a reliable, fast, and easy-to-use machine that delivers on its promises.

On the other hand, a significant number of users have encountered quality control issues that soured their initial experience. The most common complaint, as we noted, is the Z-axis issue where the nozzle crashes into the bed. But other problems have surfaced as well, such as a user who received two consecutive machines with a defective hot bed connector, calling it a “potential fire hazard.” Another particularly concerning report involved a user discovering their new machine contained an 8-bit motherboard from over five years ago, directly contradicting the “2025 Model” branding. This feedback suggests a lottery: if you get a good unit, you’ll be ecstatic. If you get a problematic one, be prepared for troubleshooting or returns. The value is there, but so is the risk of needing to work through some initial kinks.

How Does the Creality K1 SE 3D Printer High-Speed Compare to the Competition?

In the rapidly evolving world of 3D printing, the Creality K1 SE 3D Printer High-Speed doesn’t operate in a vacuum. Several compelling alternatives cater to different needs and budgets, from multi-color printing to ultra-high-resolution resin models and industrial-grade machines. Here’s how it stacks up against some of the top contenders.

1. ANYCUBIC Kobra S1 Combo Multicolor 3D Printer with ACE PRO

- 【Multicolor Printing Up to 8 Colors】The Anycubic Kobra S1 Combo can achieve 4-color printing. With 2 Anycubic Ace Pros are combined, you can then unleash max 8-color printing to bring you even...

- 【Ace Pro More Than Just Active Drying】Active drying、intelligent mult-filament drying and anti-entanglement design improve the success of printing. Dual PTC heating module + 360° hot air...

The Anycubic Kobra S1 offers a similar high-speed FDM printing experience but comes with a killer feature: the ACE Pro multi-filament system. This allows for printing in up to four different colors or materials simultaneously. For creators who want to produce vibrant, multi-color models without the tedious process of manual filament swaps, the Kobra S1 Combo is the clear winner. While the Creality K1 SE 3D Printer High-Speed is a speed-focused workhorse for single-color prints, the Anycubic Kobra S1 is the artist’s choice, prioritizing aesthetic versatility alongside its impressive speed. If your primary goal is creating visually striking, colorful objects, the extra investment for the ACE Pro system is well worth it.

2. ELEGOO Saturn 4 Ultra 16K Resin 3D Printer

- 【16K Magic, Precision Redefined】Designed to capture the finest details for exquisite models, ELEGOO Saturn 4 Ultra 16K Resin 3D Printer boasts ultra-high resolution, ensuring that every model...

- 【Smart Tank Heating, Flawless Prints at 30 °C】ELEGOO Saturn 4 Ultra 16K 3D Resin Printer features an intelligent tank heating system that continues heating the resin to keep it at a perfect 30...

This is a comparison of two entirely different technologies. The ELEGOO Saturn 4 Ultra is a resin (SLA) printer, not a filament (FDM) printer. Instead of melting plastic, it uses UV light to cure liquid resin layer by layer. The result is an astonishing level of detail, thanks to its 16K resolution, making it the ideal choice for printing tabletop miniatures, intricate jewelry, or detailed dental models where surface finish is paramount. The trade-off is a smaller build volume, a messier workflow involving chemicals and post-processing (washing and curing), and stronger fumes. The Creality K1 SE 3D Printer High-Speed is for functional parts, rapid prototyping, and large-scale objects. Choose the Elegoo for detail; choose the Creality for speed, size, and material strength.

3. R QIDI TECHNOLOGY MAX3 High-Speed 3D Printer

- 【Large Format & High-speed 3d printer】 Upgrade maximum speed 600mm/s and 20000mm/s² acceleration, 325*325*315mm printing size. Fully assembled and auto leveling, Featuring Klipper firmware and...

- 【Stable and long term usage】X-Max3 have Ultra-stable all-metal frame, 6mm thickness aluminum heatbed plate, 10mm width belt, ⌀10mm hardened hollow steel linear shafts, ensures smooth and stable...

The QIDI MAX3 represents a step up into the prosumer or light industrial category. While it matches the Creality’s high speeds, its key advantages are a much larger build volume (12.8″ cubed) and, most importantly, an actively heated chamber that can reach 65°C. This heated environment is critical for successfully printing large objects with engineering-grade materials like ABS and ASA, as it prevents warping and layer splitting. The QIDI MAX3 is built for those who need to reliably print large, strong, functional parts with difficult materials. For hobbyists or those primarily using PLA and PETG, the Creality K1 SE 3D Printer High-Speed offers similar speed in a more affordable package. But for serious engineering applications, the QIDI MAX3’s heated chamber is a non-negotiable feature.

Final Verdict: Is the Creality K1 SE 3D Printer High-Speed the Right Choice for You?

After extensive testing and analysis, our verdict on the Creality K1 SE 3D Printer High-Speed is one of conditional, but strong, recommendation. When you get a properly assembled unit, it is an absolute titan of performance for its price point. The sheer speed transforms the 3D printing workflow, while the rigid frame and capable direct-drive extruder produce excellent quality prints across a wide range of materials. It successfully brings pro-level speed and features down to a price that is accessible to serious hobbyists and prosumers.

However, the journey isn’t guaranteed to be smooth. The inconsistent quality control, with potential issues like Z-axis calibration flaws and even outdated components, is a significant drawback that cannot be overlooked. We recommend this printer to users who are comfortable with the idea of potentially needing to do some minor troubleshooting out of the box. If you’re willing to possibly adjust a sensor or flash a firmware update, you will be rewarded with a machine that punches far above its weight. For those seeking a pure, appliance-like experience with zero fuss, it might be a gamble. But for the enthusiast ready to unlock incredible speed and versatility, the Creality K1 SE 3D Printer High-Speed is a phenomenal value that can truly revolutionize your making. If you’re ready to leave slow print times in the past, we encourage you to explore the product’s full potential and check its current pricing online.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API