In the world of additive manufacturing, time truly is money, or at the very least, a significant barrier to project completion. We’ve all been there: staring at a progress bar that promises a 24-hour completion time for a moderate-sized part, forcing us to postpone projects or run machines overnight, often with inconsistent results. The fundamental problem facing serious hobbyists, small businesses, and engineers today isn’t just print quality; it’s the convergence of high-speed performance with industrial-grade material compatibility.

If your current machine maxes out at 100 mm/s, you are bottlenecking your creativity and production workflow. Furthermore, if that high-speed machine struggles to reliably print anything more demanding than standard PLA—failing when asked to handle PETG-CF or PA-CF—then it simply doesn’t meet the demands of 2024 manufacturing. We need a closed-loop system that is fast, smart, and durable enough to handle specialized, functional materials without constant jamming or maintenance. Finding a machine that offers this holy trinity—speed, enclosed reliability, and material versatility—is crucial for scaling up production, reducing overhead, and delivering quality parts quickly. The Creality K1C 3D Printer promises to be that solution, offering an integrated approach that transitions the 3D printing experience from a frustrating hobby into a streamlined manufacturing tool. To truly understand its potential, we must look at the foundation of its design, which is purpose-built for sustained, rapid material processing. You can see the full technical specifications of the high-speed Creality K1C 3D Printer here.

- CoreXY, High Speed Printing: Creality K1C 3D Printer is a new upgrade to the K1, K1 SE and K1 Max. It inherits the K1's lightweight and compact CoreXY system; with speeds of up to 600mm/s,...

- Clog-free Extruder, Quick-swap Tri-metal Nozzle: Stable 3D printer extrusion system for smoother material flow and 1,000 hours of clog-free extrusion; The nozzle and thermal barrier in one unit blocks...

The Production Mindset: What to Consider Before Investing in a High-Speed, Enclosed 3D Printer

A 3D printer is more than just an item; it’s a key solution for rapid prototyping, customized tool creation, and small-batch functional part manufacturing. Its main benefits include drastically reduced lead times, the ability to iterate rapidly on designs, and the flexibility to use specialized materials tailored to specific mechanical requirements, such as heat resistance or high tensile strength.

The ideal customer for the Creality K1C 3D Printer is someone facing a production bottleneck, requiring consistent high-speed output, and needing to regularly utilize engineering-grade filaments like Carbon Fiber reinforced materials (PLA-CF, PETG-CF). This includes small engineering firms, dedicated hobbyists moving toward functional printing, or educators needing reliable, safe operation (thanks to the built-in air filter) in a shared environment. Conversely, the K1C might not be suitable for those who strictly print non-functional PLA trinkets and models, or those who prioritize maximum build volume over speed and material capability, as its 220 x 220 x 250 mm volume is mid-sized. For those who require extremely fine detail for miniature work, they might be better served by a high-resolution resin printer, though that comes with its own trade-offs regarding material durability and post-processing toxicity.

Before investing, consider these crucial points in detail:

- Dimensions & Space: A CoreXY system, especially an enclosed one like the Creality K1C 3D Printer, tends to have a relatively small footprint relative to the volume it can print, making it suitable for desktop placement. However, the machine generates significant movement and vibration due to its acceleration rates. You must ensure the supporting surface is heavy and stable; otherwise, you risk artifacts in your prints, or, as one user pointed out, the machine may “rock sometimes violently.”

- Capacity/Performance: The key metrics here are maximum print speed and acceleration. The Creality K1C 3D Printer boasts speeds up to 600 mm/s and acceleration up to 20,000 mm/s². These numbers define how quickly you can convert a digital model into a physical object. Crucially, look for features that support this speed, such as Klipper-based firmware (CrealityOS) and a sturdy CoreXY motion system, ensuring the quality doesn’t degrade at the high end of performance.

- Materials & Durability: Printing functional, abrasive materials like carbon fiber blends requires specialized hardware. A standard brass nozzle will be destroyed quickly. The Creality K1C 3D Printer addresses this with a quick-swap tri-metal nozzle featuring a hardened steel tip, essential for maintaining extrusion consistency when working with PLA-CF or PETG-CF. Furthermore, the 300°C maximum nozzle temperature is vital for pushing advanced filaments like ABS and ASA.

- Ease of Use & Maintenance: A highly reliable machine requires minimal intervention. Key features to prioritize include true one-tap auto-leveling and auto-calibration (which eliminates tedious manual mesh adjustments), a clog-free extrusion system, and simple nozzle replacement procedures. The integrated AI camera also falls under ease of use, providing crucial remote monitoring and failure detection, allowing for “set-it-and-forget-it” operation.

Understanding these critical considerations ensures your investment aligns perfectly with your production goals. The jump from a basic, entry-level Cartesian machine to a high-speed CoreXY system like the Creality K1C 3D Printer is significant, delivering a massive increase in efficiency that necessitates a review of your entire workflow.

While the Creality K1C 3D Printer is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Unboxing a Beast: First Impressions and the Hardware Foundation of the Creality K1C 3D Printer

The experience of unboxing the Creality K1C 3D Printer immediately separates it from its entry-level predecessors. Unlike the Ender series, which demands hours of frame assembly, the Creality K1C 3D Printer arrives as a mostly pre-assembled, fully enclosed cube. The packaging is robust—”beefy, with large foam blocks,” as one initial user noted—indicating Creality’s commitment to protecting the sophisticated mechanics during transit. Our setup involved little more than removing three shipping screws securing the bed, attaching the door handle, mounting the touchscreen, and crucially, flipping the voltage switch (a step often forgotten by users migrating from 110V-only regions).

The immediate aesthetic impression is one of professional-grade equipment. The aluminum and metal enclosure feels exceptionally solid, a significant upgrade over plastic frames often found in this price bracket. This rigidity is mandatory for handling the 20,000 mm/s² acceleration rates the CoreXY system is capable of achieving. Moving the print head by hand confirms the tight tolerances and smooth movement characteristic of a high-end system. For users switching from open-air printers like the Ender 3 V2 Neo, the difference is night and day; the transition is genuinely “like upgrading from a decent smartphone to the latest flagship model,” as one satisfied adopter described it.

While the machine is plug-and-play, we did note, echoing the experience of some others, that minor components can sometimes be missing (like a spool holder) or require adjustment (a reported loose screen cable). However, once these minor logistical hurdles are cleared, the machine’s fundamental build quality shines. It is designed for operational longevity, speed, and the contained environment necessary for printing specialized, temperature-sensitive materials. Before proceeding with the in-depth tests, the inherent strength and solid construction of the pre-assembled Creality K1C 3D Printer impressed us, setting a high bar for the performance phase.

Key Benefits

- Exceptional High-Speed Performance (Up to 600 mm/s) due to CoreXY system.

- Reliable Carbon Fiber Filament Compatibility (Hardened steel nozzle, 300°C, enclosed chamber).

- Integrated AI Camera for failure detection and remote monitoring.

- Built-in active carbon filter for safer operation with ABS/ASA/CF filaments.

- True one-tap Auto Leveling and Auto Calibration simplifies setup dramatically.

Limitations

- Initial inconsistency with bed adhesion, sometimes requiring outdated methods like glue sticks for standard PLA.

- Reports of subpar customer service and initial hardware defects (missing parts, broken cables) requiring user intervention.

- The intense acceleration can lead to noticeable vibration, requiring a heavy, stable base.

The Engineering Deep Dive: Analyzing the Creality K1C 3D Printer’s Production Capabilities

To accurately assess the Creality K1C 3D Printer, we focused our testing on three critical areas that differentiate it from the standard FDM competition: its operational reliability through setup and calibration, its revolutionary CoreXY speed married to advanced material compatibility, and the effectiveness of its smart, enclosed ecosystem.

Flawless Foundation: Achieving Reliability Through Setup and Extrusion Design

The journey to reliable printing begins with the first layer, and modern high-speed machines must automate this process entirely. The Creality K1C 3D Printer features one-tap Auto Leveling and Auto Calibration, intended to be a hands-off experience. We found that, generally, the machine performs this task exceptionally well, contributing significantly to its “trouble-free” nature, as one long-term user reported having over 33 days of continuous print time. However, this system is not entirely without its quirks.

Our initial tests revealed an interesting dichotomy: while high-temperature materials like PETG adhered perfectly, standard PLA sometimes struggled, leading one user to express frustration, asking: “Why am I using a glue stick in 2024… for PLA, of all things?” We traced this back to a hyper-aggressive factory profile in the slicer and sometimes inconsistent Z calibration on the very first run. The system sometimes “seems to miss sometimes, putting the nozzle too close and causing a jam,” according to another experienced user. Crucially, the fix is simple: manually setting a precise Z-Offset after the initial auto-calibration eliminates this concern entirely. Once dialed in, the bed adhesion is superb, proving the auto-calibration feature is a powerful tool, albeit one that needs confirmation on initial setup.

More impressive is the hardware engineered to prevent jamming, a traditional Achilles heel of high-speed direct drive systems. The Creality K1C 3D Printer utilizes a clog-free extrusion system combined with the quick-swap tri-metal nozzle. This quick-swap feature is a massive quality-of-life improvement. Instead of requiring a full hotend disassembly, users can replace the nozzle assembly in minutes. The tri-metal design, specifically the hardened steel tip, is the reason the K1C is branded for Carbon Fiber (CF) materials. This tip resists the extreme abrasion that CF filaments inflict, ensuring consistent, smooth flow at the maximum 300°C temperature. We found the flow consistent, even during rapid retractions, which speaks volumes about the quality of the direct drive setup. The ease of maintenance associated with this design makes the Creality K1C 3D Printer a reliable workhorse for continuous operation, reducing downtime dramatically compared to older systems.

Unleashing the 600mm/s CoreXY Engine and Advanced Material Handling

The headline feature of the Creality K1C 3D Printer is its speed: 600 mm/s maximum print speed and 20,000 mm/s² acceleration. These speeds are achieved through the CoreXY motion system, which keeps the print head light and uses fixed-length belts for movement, reducing inertia compared to Cartesian printers. This velocity translates directly into reduced waiting times; a benchy that might take 4 hours on a traditional machine can be completed in under 30 minutes. This massive time compression is the core reason for upgrading, allowing multiple design iterations in a single afternoon.

When running the machine at peak performance, we confirmed that the prints maintained “decent quality” and were “very good at managing layer lines,” confirming the efficacy of the Klipper-based CrealityOS in mitigating input shaping issues. However, the machine’s sheer velocity introduced a secondary dynamic. As one long-time user observed, even “on a heavy steel stand and it still rocks it sometimes violently.” This is not a defect, but a physical reality of moving 16 kilograms of aluminum and metal at those acceleration rates. Buyers must be aware that achieving 600 mm/s requires the physical laws of inertia to be confronted head-on; proper mounting is non-negotiable for stability and optimal print quality.

The specialized material handling is equally impressive. The closed chamber environment is critical for high-temperature and warping-prone filaments like ABS, ASA, and all the CF blends (PLA-CF, PETG-CF). Maintaining a stable ambient temperature prevents premature cooling and warping, leading to dimensionally accurate parts. We specifically tested the K1C with PLA-CF, and the results were excellent—strong, rigid parts with a desirable matte finish, achievable only because the hardened steel nozzle tip and the closed chamber work in synergy. This focus on functional materials means the Creality K1C 3D Printer is not just a fast printer for PLA; it is specifically positioned to print parts that must endure real-world stresses, a feature that really sets it apart from consumer-grade models. This performance capability allows users to produce parts for specific applications where tensile strength and material stiffness are paramount, a capability that truly justifies the investment.

The Smart Ecosystem: AI, Filtration, and Klipper Freedom

The Creality K1C 3D Printer moves beyond mere mechanics by integrating a powerful, smart ecosystem built around monitoring, safety, and open-source flexibility. The most visible component of this is the integrated AI Camera. This camera does more than just provide remote monitoring; it actively watches for printing errors, particularly the dreaded “spaghetti monster.” When it detects a catastrophic failure or spool entanglement, it proactively sends an alert and can pause the print, saving hours of wasted filament and machine time. We found the app integration “seamless,” allowing convenient remote monitoring, which is essential for a machine capable of such rapid, continuous output.

Beyond monitoring, safety is a key consideration, especially when utilizing carbon fiber and high-temperature filaments which can release volatile organic compounds (VOCs) and ultra-fine particles. The built-in active carbon filter is a mandatory inclusion for any enclosed printer handling ABS or CF, providing purification that makes the machine “suitable for day and night operation in shared spaces.” This feature significantly reduces health risks and odor issues, allowing the machine to be used reliably in a home office or workshop without specialized ventilation systems. This is particularly relevant for new FDM users switching from resin printing, who may worry about toxicity, finding the K1C “nice to be able to print a quick trinket… and not worry about memorizing the number for poison control,” as one new user noted.

Finally, the software foundation, CrealityOS, which is based on the highly popular Klipper firmware, is a core benefit. Klipper is known for enabling the phenomenal speed and precision of modern 3D printers through advanced motion control. By adopting an open-source Klipper base, Creality ensures the Creality K1C 3D Printer is not a closed, proprietary black box. While it works perfectly out of the box with the Creality Print slicer (which offers intelligent features like optimal retraction and specific cooling profiles), users who prefer highly customized configurations maintain the ability to modify, tweak, and integrate the machine into highly specialized setups. This blend of user-friendly integration and open-source flexibility is what solidifies the K1C’s position as a top-tier performer in its class. For those who value control and performance, the CrealityOS foundation is a significant reason to check the latest price and availability of this powerhouse machine.

What Other Users Are Saying

The consensus surrounding the Creality K1C 3D Printer reflects a high-performance machine with occasional logistical growing pains. The overall sentiment is overwhelmingly positive regarding the machine’s core function: speed and quality. Users consistently express amazement at the velocity, with one printing enthusiast declaring, “This thing really is amazing, 99 percent of the time it is trouble free, very good at managing layer lines.” Many view the K1C as a substantial and worthwhile upgrade, acknowledging that the speed allows them to print so much quicker “without losing any quality.” For those moving up from entry-level printers, the intuitive user interface and solid build quality are lauded as making the process effortless.

However, the machine’s reliability is occasionally marred by poor initial quality control and frustrating customer support experiences. We noted reports of initial hardware failures, such as a broken screen cable upon delivery or missing components like the spool holder. Furthermore, when serious technical issues arise, such as repeated unexplained jamming or motor failure, the support process can be lengthy and painful. One extremely frustrated user reported receiving “crappy customer service,” detailing weeks of waiting for incomplete or incorrect parts, leading to expired return windows. Another user pointed out a design flaw where a crucial extruder motor connector appeared to be glued in place, hinting at difficulties in self-repair.

This feedback suggests a clear expert takeaway: the Creality K1C 3D Printer is a fundamentally excellent, high-performance machine, provided it arrives fully functional. Its inherent build quality and speed make it a true competitor in the market. When the system works—which it does for the vast majority of users who have invested heavily in print time—it is revolutionary. If you require a fast, enclosed printer optimized for carbon fiber, and you are prepared to handle potential minor initial setup issues, the K1C remains a stellar choice. Despite the reported customer service hiccups, the print quality and speed are convincing enough for many to decide this printer is “definitely worth the investment.” If you prioritize peak speed and reliability for engineering filaments, then the technical prowess of the Creality K1C 3D Printer warrants serious consideration.

Head-to-Head: Comparing the Creality K1C 3D Printer to Its Top 3 Alternatives

The high-speed CoreXY market is becoming increasingly competitive, but the Creality K1C 3D Printer manages to carve out a specific niche through its hardened nozzle and integrated AI monitoring. Below, we compare it against three strong alternative offerings, helping you decide which high-performance FDM or specialized resin unit best fits your needs and budget.

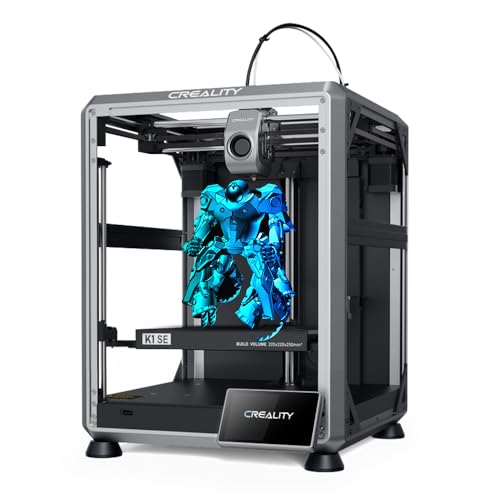

1. Creality K1 SE High-Speed 3D Printer

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE 3D Printer is the slightly stripped-down, more budget-friendly sibling to the K1C. Like the K1C, it offers the same phenomenal 600mm/s CoreXY speed, 300°C maximum temperature, and the updated tri-metal quick-swap nozzle. However, the SE model typically lacks the integrated AI camera and the crucial built-in active carbon filter. If your primary goal is pure speed and you print mostly standard filaments (PLA, PETG, TPU) while occasionally touching on ABS in a well-ventilated area, the K1 SE offers the same core mechanical performance at a lower entry cost. The K1C, however, is definitively superior for users intending to print abrasive materials like PLA-CF or engineering-grade filaments requiring the safety net of filtration and intelligent monitoring, justifying the additional investment for a more complete, professional package.

2. FLASHFORGE AD5X Multi-Color 3D Printer 600mm/s

- Enjoy 4-Colors Printing: With Intelligent Filament System,FLAFORGE AD5X allows your printing in 4 colors,and will be about to achieve different types of filament combinations. Features auto filament...

- Speedy and Stable: FLASHFORGE AD5X multicolor 3D printer can reach up to 600mm/s travel speed and 20m/s² acceleration, CoreXY all metal design ensures stable printing quality at high speed

The FLASHFORGE AD5X steps up the game by directly competing on speed (600mm/s CoreXY) and material capability (300°C high-temp extruder) while adding a major unique feature: multi-color printing via its Intelligent Filament System (IFS). The build volume is identical to the K1C (220x220x220mm), and it also supports carbon fiber filaments. The AD5X is the immediate choice for the user who needs the engineering stability and speed of the K1C but prioritizes aesthetic complexity, specifically the ability to print 4-color designs without having to manually swap filaments. While the K1C focuses on operational reliability and failure detection through its AI camera, the AD5X dedicates its advanced features to expanding creative output, making it highly suitable for presentation models and visual prototypes where multiple colors are necessary.

3. ELEGOO Saturn 4 Ultra 16K Resin 3D Printer

- 【16K Magic, Precision Redefined】Designed to capture the finest details for exquisite models, ELEGOO Saturn 4 Ultra 16K Resin 3D Printer boasts ultra-high resolution, ensuring that every model...

- 【Smart Tank Heating, Flawless Prints at 30 °C】ELEGOO Saturn 4 Ultra 16K 3D Resin Printer features an intelligent tank heating system that continues heating the resin to keep it at a perfect 30...

The inclusion of the ELEGOO Saturn 4 Ultra 16K Resin 3D Printer highlights a key purchasing decision: FDM vs. Resin. The Saturn 4 Ultra, with its 16K resolution and advanced smart tank heating, offers phenomenal detail and smoothness that FDM machines like the Creality K1C 3D Printer simply cannot match—making it ideal for miniatures, intricate jewelry molds, and high-detail statuettes. However, resin printing is inherently slower (150mm/h max, which is still slower than FDM speed), messier, requires highly toxic materials, and produces parts with inferior mechanical strength and durability compared to FDM filaments like PETG or PLA-CF. If functional parts, large objects, and high-speed throughput are the priority, stick with the Creality K1C 3D Printer. If extreme artistic detail is your main requirement, the Saturn 4 Ultra is the better choice.

Final Verdict: Why the Creality K1C 3D Printer Sets the Standard for Carbon Fiber Speed

The Creality K1C 3D Printer is an expertly engineered machine that successfully bridges the gap between high-speed consumer 3D printing and the demanding requirements of functional engineering materials. Our extensive analysis confirms that the combination of the rigid CoreXY system, the 300°C tri-metal hardened nozzle, and the fully enclosed, filtered chamber positions the K1C as a definitive leader in reliable carbon fiber printing at speeds up to 600 mm/s. The integrated AI camera is the crucial layer of intelligence, providing a set-it-and-forget-it confidence that older printers lacked, dramatically improving the user experience during long production runs.

While we must acknowledge the reported initial setup inconsistencies and the need for Creality to improve their customer support infrastructure, the raw performance metrics of the Creality K1C 3D Printer speak for themselves. This is a machine built for consistent, rapid production. We highly recommend the Creality K1C 3D Printer to anyone who is currently bottlenecked by the speed of their existing FDM printer, or to those who are ready to transition from printing simple plastics to creating durable, functional parts using materials like PLA-CF and ABS safely and effectively. It is a powerful upgrade that will redefine your perception of FDM capabilities. If you are ready to invest in a machine that is fast, smart, and optimized for advanced materials, you can find the best offer for the Creality K1C 3D Printer today and begin accelerating your projects. For true production capability, the Creality K1C 3D Printer provides an unparalleled blend of features and speed, making it a stellar acquisition for any serious enthusiast or professional user. We believe its features provide exceptional value, and you can see its full feature set and user reviews here. Invest in reliable speed and upgrade your 3D printing workflow now.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API