There’s a unique frustration every seasoned 3D printing enthusiast knows. It’s the moment you finish sculpting a magnificent digital model—a detailed dragon, an intricate cosplay helmet, or a complex architectural piece—only to face the sobering reality of your printer’s build plate. The slicing begins. You spend hours meticulously cutting your creation into a dozen smaller pieces, planning for seams, adding keys, and praying that everything will align perfectly after printing and curing. We’ve been there, and it’s a creative buzzkill. For us, the dream has always been to hit “print” on a large, seamless model and see it emerge in one glorious piece. This hunt for a printer that could match our ambition, without demanding an industrial-sized budget, led us directly to the doorstep of large-format MSLA printers. The promise of a massive build volume combined with the exquisite detail of resin printing is the holy grail for many creators, but it often comes with its own set of challenges: exorbitant cost, complex setup, and inconsistent results. This is the problem the ELEGOO Jupiter SE 3D Printer 6K LCD aims to solve.

- 【12.8-Inch 6K Mono LCD】Jupiter SE comes with a 12.8-inch 6K monochrome LCD, boasting a resolution of 5448x3064 and 51-micron XY resolution, which ensures that every intricate detail of your...

- 【Spacious Build Volume】With a build volume of 277.848 x 156.264 x 300 mm³/10.94x6.15x11.81 inches, this provides you ample space for more ambitious projects. You can print larger models or...

What to Consider Before Buying a Large-Format Resin 3D Printer

A large-format resin 3D Printer is more than just an item; it’s a key solution for breaking free from the constraints of smaller build volumes. For small business owners, prop makers, and serious hobbyists, it unlocks the ability to produce bigger, stronger, and more intricate parts in a single print run. This eliminates the tedious and often imperfect process of assembling smaller components, saving time and improving the structural integrity and aesthetic quality of the final product. The main benefits are efficiency, scale, and the potential for a higher level of professionalism in your creations. It transforms ambitious projects from logistical nightmares into straightforward printing jobs.

The ideal customer for this type of product is someone facing the constant need to print large objects or produce multiple smaller items in a single batch. This includes Etsy store owners creating statues, cosplayers fabricating armor and props, or engineers prototyping large mechanical parts. They should have some prior experience with resin 3D printing, as these larger machines introduce new variables like FEP suction forces and require more resin and post-processing space. Conversely, it might not be suitable for those who are absolute beginners to 3D printing or have very limited workspace. The physical footprint and the smell associated with large vats of resin are significant considerations. For those just starting out or needing functional, durable parts over fine detail, a high-speed FDM printer might be a more forgiving and cost-effective entry point.

Before investing, consider these crucial points in detail:

- Dimensions & Space: The ELEGOO Jupiter SE is a tall machine, standing over two feet high. You need to account not just for its footprint (18.9″ x 14.84″) but also for the vertical clearance needed to remove the UV cover. Consider the entire workflow: where will you place the printer, the large washing and curing stations, and your resin storage? A well-ventilated space is non-negotiable.

- Capacity/Performance: The key specs here are the build volume (10.94 x 6.15 x 11.81 inches) and the XY resolution (51 microns from its 6K screen). This combination allows you to print large models with very fine details. However, larger prints mean longer print times and a higher risk of failure, so understanding how to properly support large models is critical for success.

- Materials & Durability: The printer itself is built like a tank, with a sturdy alloy aluminum and steel frame. It’s designed to handle the stresses of large prints. You’ll be working with various types of UV resin, so compatibility is key. Features like the laser-carved build plate are designed to improve adhesion and reduce print failures, which is paramount when a single print can consume over a liter of resin.

- Ease of Use & Maintenance: While features like the 4-point leveling system aim for a “set it and forget it” experience, our testing confirms what some users have found: a large printer requires more tinkering. The automatic resin feeder is a major convenience feature but has its own quirks. Long-term care involves cleaning the vat, replacing the FEP film, and ensuring the Z-axis lead screws are clean and lubricated. You can explore its full feature set and maintenance guides to be better prepared.

This category of printer represents a significant step up in capability, and while it’s an exciting prospect, it’s important to be prepared for the learning curve that comes with it.

While the ELEGOO Jupiter SE 3D Printer 6K LCD is an excellent choice for scaling up your projects, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, especially if you’re exploring more budget-friendly options, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

First Impressions: Unboxing a Gentle Giant

The arrival of the ELEGOO Jupiter SE 3D Printer 6K LCD is an event. The box is substantial, and the printer inside is securely encased in foam. Assembly is refreshingly straightforward; you attach the build plate, resin tank, cover handles, and the automatic resin feeder module. The all-metal construction feels incredibly robust and inspires confidence right out of the box. It has the professional, no-nonsense aesthetic that ELEGOO is known for. The most immediate and striking feature is its sheer verticality. Unlike many printers that are wide, the Jupiter SE is tall, and the entire UV cover lifts off rather than hinging open. As one user noted, this is an odd design choice for a machine nearly three feet tall, and we concur. It means you need significant overhead clearance and a stable surface to place the large, cumbersome lid during print removal. Despite this ergonomic quirk, the initial impression is of a serious, well-built machine designed for ambitious work. Getting it set up and ready for its first leveling test took us less than 30 minutes, a testament to ELEGOO’s refined user experience, even on a machine of this scale. You can check the latest price and availability to see if this powerhouse fits your workshop’s budget.

What We Like

- Massive build volume allows for large, single-piece models or batch production.

- Excellent 6K resolution provides stunning detail (51-micron XY) even on a large scale.

- Robust all-metal construction ensures stability and longevity.

- Automatic resin feeder is a huge convenience for long prints (with caveats).

Limitations

- Auto-resin feeder is proprietary and only works with specific ELEGOO bottles.

- Leveling and first-layer adhesion can be challenging and require significant tinkering.

Performance Deep Dive: Putting the Jupiter SE to the Test

A spec sheet can only tell you so much. The true measure of a printer this large is in its performance over long, demanding prints. We ran the ELEGOO Jupiter SE 3D Printer 6K LCD through a gauntlet of tests, from full-plate batches of tabletop miniatures to a single, massive bust that took nearly 30 hours to complete. Our experience revealed a machine of immense capability, albeit one that demands respect and a bit of patience to master.

The Main Event: Jaw-Dropping Build Volume and 6K Detail

Let’s be clear: the reason you buy this printer is for its cavernous build volume. At 277.8 x 156.2 x 300 mm, it fundamentally changes what you can create. We printed a full-sized wearable helmet in one go, something that would have required at least four separate prints and a lot of post-processing on our smaller Mars series printers. The final product was seamless, strong, and perfectly proportioned. This is where the Jupiter SE truly shines. The magic, however, is that this scale doesn’t come at the expense of detail. The 12.8-inch 6K monochrome LCD, with its 5448×3064 pixel array, delivers a 51-micron XY resolution. In practical terms, this means that even when stretched across a nearly 11-inch build plate, the details are crisp and sharp. We printed a batch of 28mm miniatures that filled the plate, and each one exhibited fine textures, clear facial features, and delicate weapon details indistinguishable from those printed on a smaller, dedicated 4K printer. The combination of scale and precision is genuinely impressive and a feature that really sets it apart in its price bracket. The COB light source, flanked by cooling fans and copper heat pipes, provided consistent light uniformity across the entire plate, ensuring that models on the edges were just as perfectly cured as those in the center.

The Learning Curve: Leveling, Adhesion, and Ergonomics

While the print quality is superb, getting there isn’t always a walk in the park. This is not a beginner’s machine. The 4-point leveling system is designed to be simple, and for the most part, it is. You loosen four bolts, home the platform using a piece of paper, and tighten them back up. However, on a build plate this large, the physics of FEP suction and peel forces are magnified. As several users reported, achieving perfect first-layer adhesion is a delicate process. We found that our initial prints failed to stick consistently until we took extra steps. Following user advice, we gently scuffed the laser-carved build plate with fine-grit sandpaper and thoroughly cleaned it with IPA. This dramatically improved adhesion. We also had to increase our bottom layer exposure times slightly beyond the recommended defaults in the slicer. It’s a process of trial and error, a “dialing-in” phase that experienced users will be familiar with but could frustrate newcomers. The previously mentioned lift-off lid design is another ergonomic hurdle. It’s manageable, but a hinged or gull-wing door design would have been far more convenient for a machine of this stature. It’s a testament to the print quality that these initial frustrations are worth overcoming.

The Automated Resin System: A Glimpse of the Future, With Strings Attached

One of the most talked-about features is the automatic resin feeding and recycling system. For a 30-hour print that consumes over 1.5kg of resin, not having to manually top up the vat is a godsend. When it works, it’s brilliant. The system uses a special cap with a tube that you attach to an ELEGOO resin bottle, which is then placed upside-down in the feeder module. It senses the resin level in the vat and adds more as needed, ensuring your print never runs dry. The recycling function is equally clever, helping to pump unused resin back into the bottle to minimize waste. However, this system is the printer’s Achilles’ heel, as pointed out by multiple users. The primary issue is its proprietary nature. The caps are designed exclusively for ELEGOO’s 1kg bottles. If you prefer a different brand of resin, or a color/type that ELEGOO doesn’t offer, you’re out of luck. You’ll have to either decant your preferred resin into an empty ELEGOO bottle or forgo the feature entirely and fill the vat manually. During our testing, we experienced a moment where the feeder failed to dispense, just as one user reported, forcing us to pause the print and add resin by hand. While ELEGOO’s customer service is known to be excellent, this design choice feels unnecessarily restrictive. It’s an amazing convenience feature that is held back from true greatness by vendor lock-in, but for those who are happy to use ELEGOO resin, it’s a massive quality-of-life improvement for multi-day prints.

What Other Users Are Saying

Our findings are strongly echoed in the broader user community. There is a clear consensus that the ELEGOO Jupiter SE 3D Printer 6K LCD delivers on its promise of large, highly detailed prints. One user praised it as an “excellent machine” for its size and detail, a sentiment we wholeheartedly agree with. However, they also correctly identify that it is “definitely not a beginner’s machine” due to the tinkering required to get prints to adhere properly, which mirrors our own initial struggles with leveling and bed preparation.

The most common point of contention revolves around the automatic resin feeder. One detailed review calls it the printer’s “extremely annoying Achilles heel,” noting that it is “barely functional” and locks users into the ELEGOO ecosystem. This limitation is a significant drawback for experienced users who have preferred brands or need specialty resins. Conversely, the high praise for ELEGOO’s customer service, even from users experiencing issues, is a recurring theme, with one noting they received quick and helpful replies despite a 12-hour time difference. This suggests that while you might face challenges, the company provides strong support to help you resolve them.

How Does the ELEGOO Jupiter SE 3D Printer 6K LCD Compare to the Alternatives?

While the ELEGOO Jupiter SE excels in high-detail resin printing, the 3D printing landscape is diverse. The alternatives presented here are FDM (Fused Deposition Modeling) printers, which excel in speed, material variety, and producing functional parts rather than ultra-fine detailed models. The choice between them depends entirely on your primary printing needs.

1. FLASHFORGE AD5X Multi-Color 3D Printer

- Enjoy 4-Colors Printing: With Intelligent Filament System,FLAFORGE AD5X allows your printing in 4 colors,and will be about to achieve different types of filament combinations. Features auto filament...

- Speedy and Stable: FLASHFORGE AD5X multicolor 3D printer can reach up to 600mm/s travel speed and 20m/s² acceleration, CoreXY all metal design ensures stable printing quality at high speed

The FLASHFORGE AD5X represents a completely different paradigm: high-speed, multi-color FDM printing. If your goal is to produce colorful, functional prototypes or consumer goods quickly, the AD5X is a compelling choice. Its 600mm/s print speed is blistering compared to the slow, layer-by-layer curing of a resin printer. Furthermore, its ability to print with up to four colors and handle high-temperature materials like PLA-CF and PETG-CF makes it far more versatile for engineering applications. A user would choose the AD5X over the Jupiter SE if their priority is speed, material strength, and multi-color capability over the absolute finest surface detail.

2. Comgrow K1C 3D Printer

- Faster and More Efficient: Creality K1C 3d printer, equips 600mm/s printing speed and 20000mm/s² acceleration, it is12 times faster than the other normal 3d printer. Give good printing experience to...

- Convenient Operation: Creality K1C is well assembled and tested before shipment. After unboxing, it is ready for plug and play. The boot-up guide is similar to that of a new smartphone. 3 minutes from...

The Creality K1C (sold by Comgrow) is another speed demon in the FDM world, also boasting a 600mm/s print speed and a focus on performance materials. Its key feature is the ability to handle carbon fiber filaments right out of the box, thanks to its 300°C high-temp, clog-free extruder. This makes it ideal for creating strong, lightweight, and durable parts for functional use, like drone frames, custom brackets, or mechanical components. Someone would opt for the K1C if their projects demand high strength-to-weight ratios and temperature resistance, areas where standard photopolymer resins fall short. It’s a workhorse for engineers and makers building things that need to perform under stress.

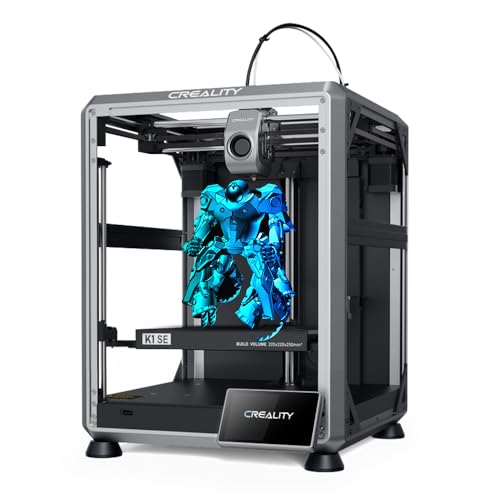

3. Creality K1 SE 3D Printer High-Speed Printing

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE is positioned as a more accessible entry into the world of high-speed CoreXY printing. It shares the impressive 600mm/s speed of its siblings but focuses on a streamlined, user-friendly experience with features like one-tap calibration and auto-leveling. It’s a fantastic choice for someone who wants to rapidly iterate on designs or produce parts quickly without the mess and post-processing of resin. A hobbyist or prototyper would choose the K1 SE over the Jupiter SE if their primary need is raw speed for PLA and PETG printing, and they value ease of use and quick turnaround times above the microscopic detail offered by resin printing.

Our Final Verdict: Is the ELEGOO Jupiter SE 3D Printer 6K LCD Worth It?

After extensive testing, we can confidently say that the ELEGOO Jupiter SE 3D Printer 6K LCD is a formidable machine for the right user. It successfully bridges the gap between smaller hobbyist printers and industrial-grade machines, offering a massive build volume and exceptional 6K detail at a relatively accessible price point. It’s a dream machine for prop makers, small business owners, and ambitious creators who are tired of being limited by a small build plate. The print quality is, without a doubt, its greatest strength.

However, it is not without its challenges. The finicky nature of leveling a large build plate, the awkward lift-off lid, and the restrictive design of the auto-resin feeder are real drawbacks that require patience and experience to overcome. This is not a plug-and-play appliance for beginners. It’s a powerful tool for makers who are willing to invest the time to understand its quirks and dial it in perfectly. If you have experience with resin printing and a burning desire to go big, the Jupiter SE will not disappoint. It unlocks a new scale of creativity that is simply thrilling to work with. For those ready to take their ambitious projects from the screen to reality in one glorious piece, we highly recommend it. You can see the current pricing and order yours here.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API