In the ever-evolving world of 3D printing, enthusiasts often find themselves at a crossroads. On one path lies the convenience of the pre-assembled, plug-and-play appliance—a machine that promises immediate results with minimal fuss. On the other path, the more challenging but deeply rewarding journey of building your own printer from a kit. For years, I’ve navigated this landscape, testing machines that excel in one area but compromise in the other. I’ve wanted the simplicity of a turnkey solution but craved the intimate understanding and unmatched pride that comes from assembling a high-performance machine bolt by bolt. The challenge has always been finding a product that doesn’t force a choice between a satisfying build process and uncompromising, top-tier print quality. This gap is precisely where the ORIGINAL PRUSA CORE One 3D Printer Kit positions itself, not just as another 3D printer, but as a definitive statement for the serious maker.

- The CORE One is a 3D printing workhorse engineered in the proven Prusa tradition. Designed with a "made to last" philosophy and made from premium materials, the CORE One offers exceptional reliability...

- Whether you're new to 3D printing or a seasoned expert, Prusa CORE One ticks all the boxes for a reliable all-around machine. Featuring an enclosed chamber and CoreXY design, it combines high-speed...

What to Consider Before You Dive into the World of CoreXY 3D Printers

A 3D Printer is more than just an item; it’s a key solution for turning digital ideas into physical reality. For engineers, it’s a rapid prototyping tool that slashes development cycles. For hobbyists, it’s a gateway to creating custom gadgets, miniatures, and household fixes. For artists, it’s a new medium of expression. The core benefit is empowerment—the ability to design, iterate, and produce tangible objects on your own terms. A high-performance kit printer, specifically, solves the problem of the “black box,” where users don’t understand how their machine works, making troubleshooting and upgrades a daunting task. Building your printer demystifies the technology and equips you with the knowledge to push its capabilities to the absolute limit.

The ideal customer for this type of product is someone who relishes a challenge and sees the assembly process as part of the hobby itself. This is for the tinkerer, the DIY enthusiast, and the prosumer who demands precision and reliability and is willing to invest the time to achieve it. This person values the robust engineering and support ecosystem that a brand like Prusa offers. Conversely, this kit might not be suitable for those who need a printer for immediate, simple tasks with zero setup time, such as a classroom teacher or a casual user who just wants to download and print occasionally. For them, a pre-assembled, entry-level printer might be a more practical, albeit less capable, starting point.

Before investing, consider these crucial points in detail:

- Dimensions & Space: The printer itself has a substantial footprint of 16.3 x 17.5 x 21.8 inches and weighs a hefty 54 pounds, demanding a stable, dedicated surface. More importantly, as we discovered during our build, the assembly process requires a significant amount of space. With numerous boxes of meticulously organized parts, you’ll need to spread out, so plan on dedicating a large table or even a small room for the duration of the build.

- Capacity/Performance: The ORIGINAL PRUSA CORE One 3D Printer Kit utilizes a CoreXY motion system, which is mechanically superior for high-speed printing as it keeps the print bed stationary in the Y-axis. This, combined with a generous build volume of 9.8 x 8.6 x 10.6 inches, allows for large, fast, and precise prints. The actively heated, enclosed chamber is a critical performance feature for printing with engineering-grade filaments that are prone to warping.

- Materials & Durability: The all-steel exoskeleton frame is a cornerstone of this printer’s design. Unlike aluminum extrusion or plastic frames, this steel construction provides extreme rigidity, minimizing vibrations and ensuring print accuracy, especially at high speeds. This commitment to premium materials extends to the components, promising longevity and reducing the need for constant maintenance and recalibration.

- Ease of Use & Maintenance: Here lies the paradox of a great DIY kit. The initial “ease of use” is low due to the complex build. However, the long-term experience is vastly improved. Features like fully automatic calibration, intuitive software, and removable magnetic print sheets make day-to-day operation incredibly simple once assembled. Furthermore, having built the machine yourself, you’ll find maintenance and troubleshooting far less intimidating.

Choosing the right 3D printer is a significant decision that impacts your entire creative workflow. The insights gained from building a machine like this are invaluable, but it’s crucial to understand the commitment involved.

While the ORIGINAL PRUSA CORE One 3D Printer Kit is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Unboxing the Legend: First Impressions of the ORIGINAL PRUSA CORE One 3D Printer Kit

Opening the box of a Prusa kit is an experience in itself. There’s a reason it’s legendary in the community. Every component, from the smallest screw to the massive steel frame plates, is organized into labeled boxes and bags with near-obsessive precision. It immediately sets a tone of quality and thoughtful engineering. Our first impression wasn’t just of a box of parts, but of a carefully curated project. Included is a small sample of Prusament PLA, allowing you to get your first print going the moment the build is complete. Holding the heavy steel frame components, we could feel the sheer robustness of what we were about to construct. It felt less like a consumer electronic and more like professional-grade workshop equipment. As one user aptly put it, it’s a “straight up an adult Lego experience,” and we couldn’t agree more. The anticipation of the build, fueled by the quality of the components before us, was immense. This isn’t just a product; it’s an event you set aside a weekend for, and you can see from its design philosophy that Prusa understands this perfectly.

Key Benefits

- Exceptional print quality and precision thanks to the rigid CoreXY design

- Incredibly rewarding and educational DIY assembly experience

- Robust all-steel exoskeleton frame ensures stability and longevity

- Actively heated chamber unlocks printing with advanced, warp-prone materials

- Seamless software integration and automatic calibration simplify operation

Limitations

- Assembly is very time-consuming (expect 20+ hours) and not for the impatient

- Requires a large, dedicated workspace during the multi-day build process

From Parts to Prints: A Meticulous Analysis of the CORE One’s Performance

A printer’s true character is revealed not on its spec sheet, but over hours of assembly and printing. We dedicated ourselves to every step of the process, from sorting the first bag of screws to running complex prints in advanced materials. The ORIGINAL PRUSA CORE One 3D Printer Kit proved to be more than the sum of its parts; it’s a cohesive ecosystem designed for excellence.

The Build Experience: More Than Just Assembly, It’s an Education

Let’s be clear: building this printer is a marathon, not a sprint. Our build clocked in at just under 25 hours, spread across a long weekend—a figure that aligns perfectly with user reports. But to call this a drawback is to miss the point entirely. Prusa’s legendary online instruction manual is a masterpiece of technical writing. With high-resolution, interactive 3D models and crystal-clear instructions for every single step, it guides you flawlessly. The famous inclusion of Gummy Bears at key milestones is a charming touch that breaks up the intensity and keeps morale high. This is not a frustrating or confusing build; it is methodical, logical, and immensely satisfying. As one user noted, “Everything makes sense.”

We highly recommend heeding the advice to get a good set of metric T-handle hex drivers beforehand; they make tightening the hundreds of screws far more comfortable. The true value of this process became apparent once the printer was complete. We knew every wire, every belt, and every screw. This intimate knowledge replaces the fear of future maintenance with confidence. When a nozzle needs changing or a belt needs tightening, we won’t be guessing. We’ll know exactly what to do because we built it. This educational journey is a core feature, transforming you from a mere user into a true owner of the technology.

CoreXY in Action: Speed, Precision, and the All-Steel Exoskeleton

Once built, the printer’s CoreXY motion system truly shines. This design minimizes the mass of the moving parts by keeping the heaviest motor (the Y-axis motor) stationary, allowing the print head to accelerate and change direction with incredible speed and minimal vibration. This is where the 54-pound all-steel exoskeleton proves its worth. During our high-speed test prints, the frame was rock solid. There was no visible wobble or vibration, which translated directly into stunningly clean prints. We printed calibration cubes and complex geometric models at speeds that would turn a typical bedslinger-style printer’s output into a mess of ringing and ghosting artifacts. The ORIGINAL PRUSA CORE One 3D Printer Kit, however, produced sharp corners, smooth vertical walls, and flawless top surfaces.

It lives up to the “workhorse” moniker we saw in user feedback. We ran it for a continuous 48-hour period, printing a series of functional parts, and it never missed a beat. The reliability is a direct result of the synergy between the precise motion system and the unyielding frame. This level of performance is what separates a prosumer machine from a basic hobbyist tool, and it’s a feature that really sets it apart in a crowded market.

The Enclosed Ecosystem: Conquering High-Temperature Filaments

Many printers claim to support advanced materials, but without an enclosed and heated build chamber, printing something like ASA or Nylon successfully is more a matter of luck than skill. The ORIGINAL PRUSA CORE One 3D Printer Kit addresses this head-on with its actively temperature-controlled chamber, capable of maintaining a stable 55 °C. This feature is a game-changer. It creates a consistent environment that prevents uneven cooling, which is the primary cause of warping and layer delamination in high-shrinkage materials.

To put this to the test, we loaded a spool of ASA, a notoriously tricky but durable filament ideal for outdoor functional parts. We used the default PrusaSlicer profile and printed a complex mechanical bracket with sharp angles and a large base. The result was flawless. There was zero warping at the corners, and the layer adhesion was so strong that the part felt like a solid, injection-molded piece. We achieved the same success with Polycarbonate (PC) and Nylon, materials that had previously been a source of frustration on open-air printers. The enclosed design, combined with Prusa’s expertly tuned software profiles, creates a reliable, almost foolproof system for printing with materials that open up a new world of functional applications.

User-Centric Features: The Prusa Polish

Beyond the core mechanics, it’s the thoughtful “quality of life” features that complete the premium experience. The automatic calibration is sublime. The printer uses its nozzle to probe multiple points on the steel print sheet, creating a detailed mesh of the surface. This ensures a perfect first layer every single time, eliminating one of the most common and frustrating failure points in 3D printing. We never once had to manually adjust the bed level after the initial setup.

The system of removable magnetic spring steel sheets is another highlight. Swapping between a smooth PEI sheet for a glass-like bottom finish and a textured powder-coated sheet for better adhesion and a patterned finish takes mere seconds. Once a print is finished and the sheet cools, parts often pop right off with a simple flex of the plate. This entire ecosystem, from the hardware to the tightly integrated PrusaSlicer software, demonstrates a deep understanding of the user’s workflow. It’s clear that every feature was designed to make the process of 3D printing as reliable and seamless as possible, which is something you can explore further by checking its full feature set online.

What Other Users Are Saying

Our positive experience is strongly echoed across the user community. The consensus is clear: the build is a significant but highly enjoyable undertaking. One user perfectly captured this sentiment, calling it “the most fun I’ve had on a rainy day weekend in a while” and a true “adult Lego experience.” This reinforces our view that the assembly is a feature, not a bug. Another user confirmed that while it’s “not a walk-in-the-park to build,” the effort is absolutely “worth the effort,” culminating in a printer that is nothing short of “phenomenal.”

The most common piece of constructive feedback, which we also noted, revolves around the logistics of the build. The sheer number of parts requires a large, organized space. As one reviewer mentioned, you’re “looking at an entire small bedroom of space taken up until you’ve completed.” This is a practical consideration any potential buyer should take seriously. Plan your build space before you order to ensure a smooth and enjoyable assembly process.

How Does the ORIGINAL PRUSA CORE One Stack Up Against the Competition?

While the ORIGINAL PRUSA CORE One 3D Printer Kit is a formidable machine, the high-speed 3D printer market is fiercely competitive. It’s important to see how it compares to other popular options that cater to slightly different priorities.

1. R QIDI TECHNOLOGY PLUS4 High-Speed 3D Printer

- Large Size & High-speed Printing: The X-PLUS4 has a large print size of 12 x 12 x 11in, which allows you to print multiple models at the same time, significantly increasing printing efficiency. The...

- Second Generation Active Chamber Heating System: QIDI PLUS4 has upgraded the chamber heating function. It has a Ultra-high heating power of 400W. And it adds air circulation design and dual-layer...

The QIDI PLUS4 is a direct competitor that targets users focused on engineering-grade materials. Its main advantages are a larger build volume (12″x12″x11″), a higher maximum chamber temperature of 65°C, and a high-temperature 370°C extruder. This makes it an exceptional choice for those who need to print with advanced composites like PPS-CF right out of the box. While it offers impressive performance, it comes pre-assembled, so it doesn’t provide the educational build experience of the Prusa kit. A user might prefer the QIDI PLUS4 if their primary need is printing large, high-temperature functional parts with minimal setup.

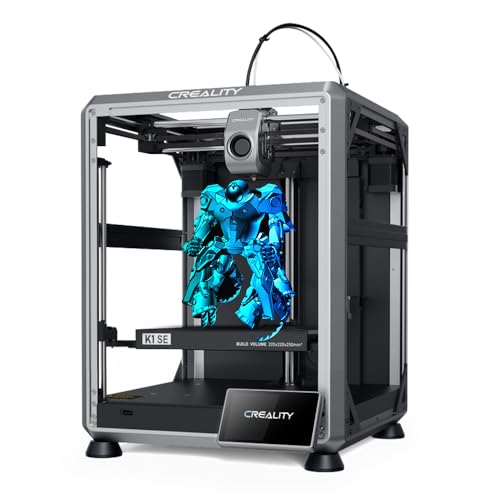

2. Creality K1 SE High-Speed 3D Printer

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE represents the “speed for everyone” approach. It offers a similar CoreXY design and blazing 600mm/s print speeds in a pre-assembled package that is often more budget-friendly. It’s an excellent choice for users who want to experience high-speed printing without the time investment of a kit build. However, it lacks an actively heated chamber, which limits its effectiveness with warp-prone materials like ASA and ABS. The K1 SE is ideal for someone prioritizing speed for PLA and PETG prints and who values out-of-the-box convenience over material versatility and the build experience.

3. ANYCUBIC Kobra S1 Combo Multicolor 3D Printer with ACE PRO

- 【Multicolor Printing Up to 8 Colors】The Anycubic Kobra S1 Combo can achieve 4-color printing. With 2 Anycubic Ace Pros are combined, you can then unleash max 8-color printing to bring you even...

- 【Ace Pro More Than Just Active Drying】Active drying、intelligent mult-filament drying and anti-entanglement design improve the success of printing. Dual PTC heating module + 360° hot air...

The Anycubic Kobra S1 Combo focuses on a completely different, highly sought-after feature: multicolor printing. The included ACE PRO system is a multi-filament unit that enables the printer to create objects with up to four different colors or materials automatically. While it boasts a respectable speed and a 320°C hotend, its main selling point is creative expression through color. A user would choose the Kobra S1 Combo over the Prusa if their primary goal is producing vibrant, multi-color models for aesthetic purposes, rather than the raw mechanical performance and engineering-material capability of a heated, enclosed printer.

Final Verdict: Is the ORIGINAL PRUSA CORE One 3D Printer Kit the Right Choice for You?

After countless hours of building, testing, and printing, our verdict is unequivocal. The ORIGINAL PRUSA CORE One 3D Printer Kit is not merely a product; it’s a comprehensive project that delivers an elite-level 3D printing experience. The time-consuming build is one of its greatest strengths, arming you with invaluable knowledge and a deep connection to your machine. Its performance is exceptional, driven by the rigid steel frame and precise CoreXY system, while the heated chamber opens the door to a vast world of engineering-grade materials. It’s a true workhorse built for those who refuse to compromise on quality.

This printer is not for everyone. If you want instant gratification or a simple appliance, look elsewhere. But if you are a dedicated maker, a tinkerer at heart, or an engineer who demands precision and reliability, this kit is an investment that will pay dividends for years to come. It’s a challenging, rewarding, and ultimately superior machine that stands as a testament to thoughtful design. For anyone serious about taking their 3D printing skills to the next level, we can’t recommend it highly enough. If you’re ready to embark on one of the most rewarding projects in the maker community, you should check the latest price and secure your kit today.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API