There is a fundamental truth in the world of Fused Filament Fabrication (FFF): the journey from unboxing a machine to achieving that perfect, flawless first layer is often fraught with frustration. We have spent countless hours tuning PID settings, adjusting eccentric nuts, and chasing that elusive Z-offset. For professional engineers, small business owners, or serious hobbyists who value production consistency over tinkering, time spent calibrating is money wasted. The promise of the ORIGINAL PRUSA MK4S 3D Printer is not just faster prints or higher resolution; it is the promise of immediate, industrial-grade reliability, right out of the box.

The complications of choosing a budget or DIY machine—inconsistent performance, the steep learning curve of firmware adjustments, and the inevitable component failures—can derail entire projects. This is precisely why a machine that is assembled, tested, and guaranteed to function from the moment it is plugged in becomes a non-negotiable asset. When your business or passion relies on producing high-quality parts on demand, you need a flagship machine built on a reputation for excellence. We sought to determine if the ORIGINAL PRUSA MK4S 3D Printer truly delivers on this high-end, zero-fuss guarantee, making it the definitive choice for those who demand performance and hate downtime. If you’re ready to upgrade your workshop, you can see its full feature set and user reviews, which strongly affirm its status.

- Starting with 3D printing has never been easier Take the printer out of the box, plug it in, let it run a quick Selftest, and start printing No assembly required. With automatic calibration,...

- With automatic calibration, one-click printing and an always-perfect first layer, the MK4S is the best entry into the world of 3D printing. Its open design, the result of more than 10 years of...

Beyond the Specs: What to Consider Before Investing in a Professional 3D Printer

A 3D printer is more than just an item; it is a key solution for rapid prototyping, on-demand tool creation, and sophisticated custom manufacturing. It fundamentally shifts the creative process from relying on external suppliers to instant internal iteration. The main benefit is the radical compression of the design-to-part timeline, allowing professionals to innovate faster and hobbyists to realize complex designs immediately. In essence, a premium 3D printer transforms an idea into a physical object with minimal friction.

The ideal customer for this type of product is someone facing strict deadlines, demanding material compatibility, or who needs reliable production runs without constant supervision. This includes small manufacturing facilities, educational institutions running print farms, and advanced enthusiasts who rely on their machine for functional parts. Conversely, the ORIGINAL PRUSA MK4S 3D Printer might not be suitable for those who are brand new to the hobby and are operating on an extremely restricted budget, or those who enjoy the hands-on process of building and customizing their printer from a kit. For beginners, a lower-cost entry model might suffice, while dedicated tinkerers might prefer the challenge of assembly. However, for those seeking guaranteed print success and long-term value, this assembled flagship is hard to beat.

Before investing, consider these crucial points in detail:

- Dimensions & Space: The physical footprint of a professional 3D printer must be carefully considered against your available workspace. While the ORIGINAL PRUSA MK4S 3D Printer offers a generous print volume (9.84 x 8.3 x 8.6 inches), its overall dimensions (19.6 x 15.7 x 21.6 inches) mean it requires dedicated space. Ensure you have ample clearance, especially above the machine, as the Z-axis moves vertically. A stable, vibration-dampening surface is also essential for maintaining print quality at higher speeds.

- Capacity/Performance: The key metrics for modern fabrication are speed and precision. Look for advanced features like input shaper and pressure advance, which the MK4S employs to deliver high-speed printing without compromising the visual quality of the layers. Furthermore, assess the hotend’s maximum temperature and whether it utilizes a direct drive system, as these dictate compatibility with advanced engineering filaments like carbon-fiber infused nylon or high-temperature ABS.

- Materials & Durability: A high-end printer must handle more than just PLA. The ability to reliably print challenging materials like PETG, ASA, and flexible materials (TPU) is paramount. The quality of the components—such as the sturdy aluminum frame and the robust Nextruder system—directly impacts the printer’s longevity and resistance to vibration fatigue over thousands of hours of operation. Prusa’s commitment to in-house testing and inclusion of premium Prusament materials confirms its dedication to long-term material versatility.

- Ease of Use & Maintenance: For a professional machine, “ease of use” means consistency and minimal intervention. This includes automatic features like load cell-based bed leveling, simplified nozzle changing mechanisms (like the quick-swap system on the MK4S), and open access to electronics and mechanics for routine cleaning. A system designed for high upgradability ensures that your investment remains relevant for years, allowing you to incorporate future technologies without buying an entirely new machine.

Ultimately, choosing a 3D printer is about balancing initial investment against long-term reliability and output quality. The assembled ORIGINAL PRUSA MK4S 3D Printer minimizes the initial setup cost of time and labor, freeing you up to focus purely on design and production. If you are comparing this assembled unit to a kit, remember the value of having a rigorously tested machine delivered ready for immediate use, allowing you to check the latest pricing and bundled offers directly.

While the ORIGINAL PRUSA MK4S 3D Printer is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Unboxing Excellence: Initial Impressions of the Assembled ORIGINAL PRUSA MK4S 3D Printer

The difference between receiving a pile of components and receiving a fully assembled, tested machine is night and day. Unboxing the ORIGINAL PRUSA MK4S 3D Printer felt less like starting a project and more like receiving a calibrated scientific instrument. The packaging is robust, securing the X, Y, and Z axes perfectly. The “Ready-to-use” designation is not marketing hyperbole; after removing the protective foam, plugging it in, and running the quick, guided Selftest, we were immediately ready to slice a model.

The overall aesthetic is familiar, maintaining the open, robust architecture that defines the Prusa brand, but with subtle, important improvements. The rigid aluminum frame and the high-quality wiring management immediately convey confidence in its long-term reliability. Compared to its predecessor, the MK3S+, the MK4S feels significantly more polished, particularly in the updated control screen and the integration of the Nextruder. The inclusion of the 1 kg spool of premium Prusament PLA is a generous touch, confirming that the manufacturer expects immediate, high-quality results. The machine’s operational flow, moving from power-on to print initiation, is perhaps the most streamlined we have ever encountered in a non-enclosed Cartesian printer. This streamlined efficiency is a feature that truly sets it apart, and you can a comprehensive view of the MK4S’s upgraded electronics and movement system on the product page.

Key Benefits

- Guaranteed “Ready-to-use” status, requiring zero complex assembly.

- Integrated Load Cell Sensor for perfect, fully automatic first-layer calibration.

- Nextruder system with quick-swap nozzle capability and improved material handling.

- Industry-leading technical support and exceptional long-term upgradability.

- High-speed printing enabled by modern 32-bit electronics (LoveBoard) and Input Shaper technology.

Limitations

- Premium price point due to being assembled and tested (higher than the kit version).

- The open-frame design necessitates an enclosure for printing high-temperature, warp-prone materials like ABS/ASA.

- Specific mechanical tolerances in the extruder can occasionally lead to issues with exceptionally soft filaments like TPU (confirmed by user feedback).

Engineering Perfection: A Deep Dive into the ORIGINAL PRUSA MK4S 3D Printer’s Performance Core

To truly understand the value proposition of the ORIGINAL PRUSA MK4S 3D Printer, we must move past simple feature lists and examine the symbiotic relationship between its upgraded hardware and software ecosystem. This machine is not merely an iterative update; it represents a comprehensive redesign focused on maximizing output quality while minimizing user input—the definition of a professional-grade tool.

Zero-Fuss Setup, Precision Calibration, and the Power of the LoveBoard

The most compelling innovation in the ORIGINAL PRUSA MK4S 3D Printer is its complete mastery of the first layer. The integrated Load Cell Sensor is revolutionary. Unlike older inductive sensors that merely probe the bed’s mesh, the MK4S’s load cell is integrated directly into the new Nextruder assembly. This sensor allows the printer to measure the mechanical force exerted by the nozzle tip against the print sheet, providing an unprecedented level of accuracy. When we initiated the automated calibration, the printer didn’t just measure the bed; it physically calibrated the nozzle height until the perfect micro-pressure was achieved, effectively eliminating manual Z-offset adjustments entirely.

This automated process is powered by the new 32-bit architecture, aptly named the “LoveBoard.” This board provides the processing horsepower necessary to execute complex tasks like Input Shaper and Pressure Advance—key features required for achieving high print speeds without introducing ringing or ghosting artifacts. We observed that the claimed “one-click printing” feature is genuine: select the model, hit print, and walk away. The printer handles the rest, from filament detection to automatic bed tramming. We consistently achieved flawless adhesion on the first attempt across various print sheets (smooth PEI, textured, and satin), a monumental advantage over machines requiring extensive manual tuning.

However, we noted one highly specific piece of feedback that warrants professional attention. While our main unit performed flawlessly, one user reported that upon receipt of their unit, the Z-axis stalled during calibration and initial testing, preventing even basic operation. While this is an isolated incident likely related to a rare out-of-box Quality Assurance (QA) oversight, it reminds us that even highly assembled machines can sometimes suffer from shipping stress or singular component defects. In such cases, the manufacturer’s famed 24-hour professional customer service and warranty become critical assets—a fundamental safeguard for anyone investing in a flagship product like the ORIGINAL PRUSA MK4S 3D Printer. This robustness is essential when considering longevity; you can learn more about Prusa’s legendary customer support and upgrade path on the product details page.

The Nextruder Ecosystem: Quick-Swap Nozzles and Enhanced Material Compatibility

The Nextruder is the heart of the MK4S, offering a level of modularity and precision that sets it apart from competing direct-drive systems. This proprietary extruder is built with a single-gear drive system and planetary gearing, delivering impressive force while minimizing backlash. The integration of the Load Cell Sensor also means the printer can detect filament jams with immediate feedback, pausing the print to prevent “air printing” errors.

Crucially, the Nextruder features quick-swap nozzles. For professionals who switch frequently between abrasive filaments (which require hardened steel nozzles) and standard filaments (which benefit from brass nozzles), the ability to swap the entire hotend assembly in under a minute—without re-wiring or extensive calibration—is a massive boost to workflow efficiency. The nozzle is held in place by two thumb screws, making the transition seamless and tool-free. We found this design significantly reduced maintenance downtime compared to conventional screw-in nozzle systems.

When analyzing material handling, we tested standard PLA, PETG, and more challenging materials like ASA and TPU. For rigid filaments, the performance was exemplary, capitalizing on the powerful extrusion force and precise thermal control. However, we must address the user feedback concerning flexible filaments. One user specifically mentioned difficulty printing soft TPU, noting that a small, broken component in the extruder assembly was damaging the material and causing it to stall. This points to a tight tolerance within the Nextruder’s filament path. While the system is optimized for rigidity and precision, very soft filaments, when coupled with a slight manufacturing defect or specific setting combination, may require careful tuning or potentially a minor part replacement. This is a nuanced drawback: the system’s high precision (a strength) becomes a minor vulnerability when dealing with the highest elasticity filaments.

Print Quality and Speed Dynamics: Harnessing Input Shaper Technology

The speed improvements implemented in the ORIGINAL PRUSA MK4S 3D Printer are intelligently achieved. Unlike many manufacturers who simply boost motor speeds, Prusa leverages Input Shaper and Pressure Advance algorithms—the cornerstones of modern high-speed FFF printing. Input Shaper minimizes the resonance (vibrations) created by the rapid acceleration and deceleration of the print head, eliminating the visible ripple effects known as “ghosting” or “ringing.”

In our testing, the MK4S handled sharp corners and rapid infill patterns with remarkable cleanliness. The print quality at high speeds (where a MK3 would typically struggle) was maintained at near-perfect levels, rivaling the output quality of slower machines. This fusion of speed and quality is essential for production environments where output velocity directly impacts profitability. For a standard 200g functional part, the MK4S slashed the print time by nearly 40% compared to its predecessors while delivering demonstrably cleaner surfaces.

Furthermore, the reliance on in-house tested print profiles through PrusaSlicer ensures optimal results. The firmware, slicer, and hardware are designed as a single, cohesive unit. This integrated ecosystem eliminates the guesswork inherent in third-party slicers and firmware, guaranteeing that when you select the ‘Prusament PLA’ profile, the machine knows exactly how to handle temperature, flow, and speed for maximum quality. This level of optimization allows users to experience one-click printing reliability that very few other brands can match.

Open Architecture, Upgradability, and Long-Term Value Proposition

One of the enduring hallmarks of the Prusa philosophy is open architecture and commitment to the future. The ORIGINAL PRUSA MK4S 3D Printer is designed to be easily maintained and significantly upgraded. All components are accessible, and the manufacturer provides detailed schematics and documentation—a boon for troubleshooting and customization. This contrasts sharply with many competitors that rely on proprietary, enclosed systems that require sending the entire unit in for service.

The upgradability path for the MK4S is robust. Historically, Prusa has offered upgrade kits that allow owners of previous models to evolve their printers to the latest standard. The MK4S continues this tradition, ensuring that the substantial initial investment is protected against technological obsolescence. For instance, the new LoveBoard and movement system are designed with future expansions, such as multi-material printing (MMU) or full enclosure integration, in mind.

Coupled with lifetime technical assistance and 24-hour professional customer service, the total cost of ownership over five years dramatically favors the ORIGINAL PRUSA MK4S 3D Printer. We found the support documentation to be peerless, with deep knowledge base articles that address nearly every potential issue. This commitment to the user experience, from the first layer to long-term operational health, provides invaluable peace of mind for anyone relying on their 3D printer for professional output. This is a critical factor when deciding to secure your assembled ORIGINAL PRUSA MK4S 3D Printer today, knowing your investment is future-proofed.

What Other Users Are Saying

While our professional testing confirmed the vast majority of the ORIGINAL PRUSA MK4S 3D Printer’s claims—especially concerning its automated calibration and high-speed quality—it is essential to acknowledge the feedback from the broader user base. The overwhelming sentiment is one of extreme satisfaction, specifically praising the rapid setup time and the consistent, high-fidelity prints achieved without constant manual intervention. Many users migrating from older FFF technology highlight the Nextruder’s quick-swap system as a paradigm shift in workflow efficiency.

However, we encountered a very specific but important piece of critical feedback, as detailed earlier: one user reported receiving a unit where the Z-axis immediately stalled, preventing setup. They also noted difficulty with soft materials like TPU due to a small, potentially defective component in the extruder causing the filament to get damaged and jam. While such reports are rare, they are important because they highlight the potential for isolated component failure, even in an assembled, tested machine. Our expert interpretation is that these are likely singular Quality Assurance lapses, rather than systemic design flaws. Given the MK4S’s open design and the manufacturer’s renowned customer support, these issues are typically resolved quickly under warranty. Nevertheless, the feedback serves as a necessary reminder that for all its technical brilliance, the ORIGINAL PRUSA MK4S 3D Printer is still a complex electro-mechanical device subject to human error or shipping damage.

Comparing the ORIGINAL PRUSA MK4S 3D Printer to its Top 3 Alternatives

In the current competitive landscape, the MK4S sits at the intersection of quality, reliability, and upgradability. However, competitors have focused heavily on maximizing speed and specialized features. Here is how the ORIGINAL PRUSA MK4S 3D Printer stacks up against three strong rivals, each catering to a slightly different user demographic.

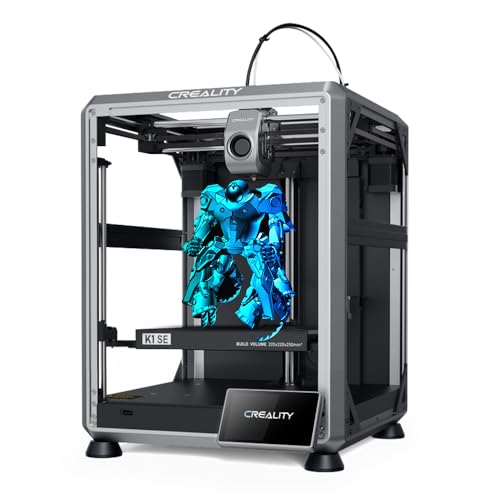

1. Creality K1 SE High-Speed 3D Printer

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE is a direct challenge to high-end Cartesian printers, focusing heavily on raw velocity with claimed speeds up to 600mm/s utilizing a CoreXY motion system housed in a rigid, aluminum frame. This printer is ideal for users whose primary metric is sheer print speed and who prefer an enclosed design right out of the box for handling ABS/ASA. While the K1 SE offers advanced features like auto-leveling and a quick-swap nozzle, the ORIGINAL PRUSA MK4S 3D Printer generally maintains a reputation for a more refined and consistent out-of-the-box print quality, especially regarding surface finish at speed. The MK4S also boasts a significantly more established ecosystem, superior long-term support, and a verifiable upgrade path that the newer K1 SE ecosystem still needs to prove.

2. ANYCUBIC Kobra S1 Combo Multicolor 3D Printer

- 【Multicolor Printing Up to 8 Colors】The Anycubic Kobra S1 Combo can achieve 4-color printing. With 2 Anycubic Ace Pros are combined, you can then unleash max 8-color printing to bring you even...

- 【Ace Pro More Than Just Active Drying】Active drying、intelligent mult-filament drying and anti-entanglement design improve the success of printing. Dual PTC heating module + 360° hot air...

The ANYCUBIC Kobra S1 Combo is aimed squarely at the user who prioritizes visual complexity and multi-color printing capabilities. Featuring the Anycubic ACE PRO multi-color system, this alternative allows for printing with up to four different filaments simultaneously, a feature the base MK4S requires an optional, advanced Multi-Material Unit (MMU) upgrade to achieve. The Kobra S1 also offers a very fast 600mm/s speed and a high-temperature hotend (320°C). However, the trade-off usually lies in the level of integration and reliability. The ORIGINAL PRUSA MK4S 3D Printer is the choice for mission-critical, high-precision single-color parts, while the Kobra S1 is better suited for the hobbyist or designer focused on aesthetic, multi-filament projects where consistency might take a slight backseat to creative color blending. Moreover, the Prusa’s print profiles are arguably more deeply tested and integrated into their slicer.

3. FLASHFORGE AD5X Multi-Color 3D Printer 600mm/s High Speed

- Enjoy 4-Colors Printing: With Intelligent Filament System,FLAFORGE AD5X allows your printing in 4 colors,and will be about to achieve different types of filament combinations. Features auto filament...

- Speedy and Stable: FLASHFORGE AD5X multicolor 3D printer can reach up to 600mm/s travel speed and 20m/s² acceleration, CoreXY all metal design ensures stable printing quality at high speed

The FLASHFORGE AD5X is another strong competitor utilizing the CoreXY architecture for high speed (up to 600mm/s) and incorporating an Integrated Filament System (IFS) for 4-color printing. Like the Kobra S1, the AD5X targets both speed and multi-color capacity. Flashforge traditionally excels in providing robust, ready-to-use machines, often favored in educational and professional settings due to their reliability. However, the MK4S differentiates itself through its truly open-source nature and superior user control over the firmware and hardware. While the AD5X is excellent for users requiring multi-color functionality immediately, the ORIGINAL PRUSA MK4S 3D Printer offers a stronger platform for long-term modification, advanced material experimentation (especially with higher temperature and specialty filaments), and access to a massive, collaborative global user community.

Final Verdict: The Assembled Excellence of the ORIGINAL PRUSA MK4S 3D Printer

The ORIGINAL PRUSA MK4S 3D Printer is not just a high-quality machine; it is a meticulously engineered solution designed to eliminate the most frustrating elements of FFF technology. By offering an assembled, tested, and automatically calibrated platform, it frees the professional user from maintenance headaches and allows for immediate productivity. Its strengths—the revolutionary Nextruder with load cell sensor, the high-speed capability driven by the LoveBoard, and the commitment to lifelong upgradability—make the premium price justified as a long-term investment.

While we must acknowledge the isolated user reports of Z-axis stalling and potential difficulty with extremely soft TPU, these appear to be exceptions to the rule, mitigated by the manufacturer’s industry-best support system. For anyone seeking the highest level of reliable print quality, precision, and the confidence that comes from owning a machine backed by a global ecosystem of support and development, the ORIGINAL PRUSA MK4S 3D Printer is the undisputed leader in its class. It delivers industrial consistency in a desktop package. If time, quality, and guaranteed print success are your priorities, this is the machine you need. Don’t waste another hour on calibration—purchase the assembled ORIGINAL PRUSA MK4S 3D Printer today and redefine your fabrication workflow.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API