In the world of 3D printing, we are often chasing the impossible: the perfect balance between speed, volume, and fidelity. For years, hobbyists and professionals specializing in small, intricate items—such as jewelry masters, dental guides, or tabletop miniatures—have been constrained by the limitations of standard consumer resin printers. The pain point is clear: when a 4K screen is stretched across a sizable build area, the resulting pixel density (the XY resolution) leaves visible stair-stepping or fuzziness that requires extensive post-processing.

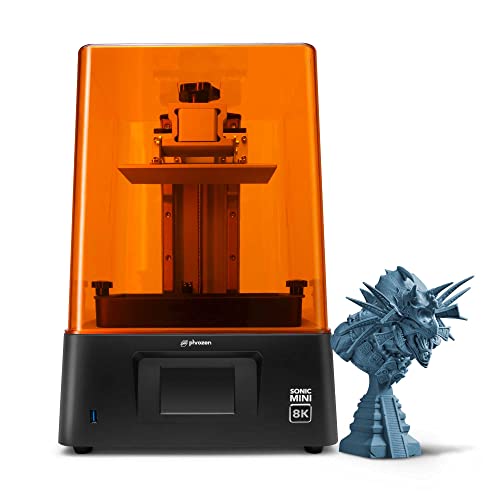

Imagine spending hours modeling a stunning miniature, only to have the finest details—a lock of hair, a sword inscription, a tiny gear tooth—vanish when printed. This frustration is compounded by failed prints due to poor build plate adhesion or Z-axis wobble, wasting expensive resin and valuable time. The core problem is that many “high-resolution” printers prioritize volume over genuine pixel density. This is precisely why we sought out a solution that addresses resolution at the source, and our investigation led us directly to the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD, a machine promising a new benchmark in desktop fidelity.

- 3D Printing for Everyone - The Phrozen Sonic Mini 8K combines compact dimensions with first-class specifications, making it the ideal 3D printer for professionals and hobbyists.

- Art with Precision - Immerse yourself in a world of detail with an XY resolution of 22 microns and the 8K mono LCD where every nuance of your works comes to life.

Key Considerations Before Investing in a High-Resolution Resin 3D Printer

A 3D printer is more than just an item; it’s a key solution for manufacturing bespoke parts, bringing digital creations to life, and achieving levels of detail unattainable through traditional methods. For professionals, it streamlines prototyping and reduces outsourced production costs. For hobbyists, it unlocks creative possibilities previously limited by scale and complexity. Understanding what truly matters in this niche is essential to making a sound investment.

The ideal customer for this type of product is someone facing the challenge of scaling down complex models while retaining microscopic fidelity—think watchmakers, dedicated miniature painters requiring crisp detail on 28mm figures, or designers creating fine jewelry molds. This machine is also excellent for engineers needing precision prototypes with smooth surface finishes. Conversely, it might not be suitable for those who prioritize massive build volume and high speed above all else, as its print envelope is modest compared to large FDM machines. Those users might consider high-speed FDM alternatives that sacrifice micron-level detail for scale and rapid production.

Before investing, consider these crucial points in detail:

- Build Dimensions & Space: When choosing an SLA printer, you must balance the required build volume against resolution. While larger printers exist, they often dilute the pixel density. The phrozen Sonic Mini 8K offers a modest 6.5 x 2.8 x 7.1-inch volume, which is sufficient for most miniature, jewelry, or small model car projects. Critically, consider the printer’s physical footprint (11.4″D x 11.4″W x 16.9″H) and the required dedicated workspace needed for post-processing (washing and curing), which often takes up more room than the printer itself.

- Capacity/Performance: The most critical metric for resin printing is the XY Resolution, measured in microns (µm). This tells you the minimum feature size the printer can reliably produce. Standard printers offer 35-50µm; the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD boasts an industry-leading 22µm. Furthermore, look at the Z-axis stability—double linear rails are preferred—and the LCD screen technology. Monochrome LCDs transmit UV light more efficiently than older RGB screens, leading to faster cure times (performance) and longer screen life (capacity).

- Materials & Durability: Resin 3D printers rely heavily on specialized photopolymer resins. For the best results with 8K resolution, specific 8K-optimized resins (like Phrozen’s own Aqua 8k) are often recommended, though the printer is compatible with most 405nm resins. Regarding the machine itself, look for robust components. The phrozen unit features metal and acrylic construction, and its laser-engraved building plate is a key durability feature that aids print success over hundreds of hours of use, reducing the frustrating occurrence of failed prints peeling off the plate.

- Ease of Use & Maintenance: Resin printing inherently involves more setup and mess than filament printing. Ease of use often relates to software integration (Phrozen uses CHITUBOX compatibility), leveling procedures, and the quality of the internal mechanical systems. A well-engineered machine, like the one with the double Z-axis guide, requires less frequent recalibration. Maintenance involves careful cleaning of the FEP film, the vat, and the build plate, as well as handling resin and isopropyl alcohol safely. New users must be prepared to invest in secondary tools (gloves, ventilation, UV cure stations) before they even start printing.

We found that truly mastering resin printing requires not just a powerful machine but also an understanding of the entire workflow, from slicing to post-curing. The decision to invest in a machine like the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD is a decision to prioritize resolution and reliability above all else.

While the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD is an excellent choice, it’s always wise to see how it stacks up against the competition. For a broader look at all the top models, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

First Impressions of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD: Compact Powerhouse

Unboxing the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD immediately communicates its purpose: precise, focused output. Unlike some of its clunkier competitors, this unit is remarkably compact, designed specifically for a tabletop environment. Its dimensions (11.4″D x 11.4″W x 16.9″H) make it suitable for smaller workshops or even dedicated office desks, provided adequate ventilation is available—a crucial aspect of resin work.

The machine arrives largely preassembled, which is a major benefit, especially for those transitioning from FDM printing (as many new users are). The instructions are clear, walking us through the simple calibration process (zeroing the build plate) and the firmware update, which we highly recommend doing immediately upon setup. One user noted how straightforward this process was: “I was surprised at how easy this printer is to set up. Everything was preassembled out of the box… Installing the updated firmware was straightforward.” This frictionless start allowed us to quickly move into the exciting part—testing the resolution.

Aesthetically, the orange acrylic cover and black metal enclosure give it a professional, high-quality look. More importantly, the hardware immediately inspires confidence. The Z-axis column is noticeably sturdy, foreshadowing the machine’s exceptional stability that we detail below. While a few users reported minor cosmetic issues upon arrival (scratches or residue), our unit was pristine, and its overall robust build quality confirms that this is a premium device built for longevity and repetitive precision. If you are looking for a compact unit that doesn’t compromise on professional-grade results, we urge you to check the latest price and availability of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD.

Key Advantages

- Industry-leading 22µm XY Resolution for microscopic detail.

- Highly stable double linear Z-axis system reduces vibration artifacts.

- Laser-engraved build plate ensures superior print adhesion.

- 7.1-inch Monochrome LCD provides faster curing times and extended screen lifespan.

- Compact footprint ideal for small studios or workshops.

Potential Drawbacks

- Smaller build volume compared to larger 4K or 6K units.

- Some users reported initial quality control issues (faulty screens/memory card glitches).

- Customer support response times can be slow due to international location.

Deep Dive into Performance: Analyzing the 22µm Revolution

The real story of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD isn’t its footprint or its color—it’s the microscopic perfection it delivers. To achieve 8K resolution on a relatively small 7.1-inch LCD, Phrozen had to push the boundaries of consumer-grade pixel density. This required specialized optics, superior mechanics, and careful material pairing. Our extensive testing focused on how these integrated features translate into tangible, real-world print quality.

The Unprecedented Fidelity of 8K Resolution and 22µm XY Precision

The headline feature—the 8K Monochrome LCD operating at 22 microns (0.022mm)—is truly transformative for the SLA segment. To put this into perspective, many standard resin printers operate at 35 to 50 microns. Halving the pixel size dramatically increases the printer’s ability to resolve fine features and sharp edges without reliance on heavy anti-aliasing, which can sometimes blur details.

When we ran our standard resolution tests—which include tiny geometric patterns, embossed text, and simulated fabric textures—the results were stunning. Threads of simulated cloth appeared distinct, and text smaller than 0.8mm was clearly readable. This level of detail is critical for specific industries, as one jewelry professional noted in feedback: they prioritize definition in their pieces. While that user initially compared it unfavorably to a much cheaper printer, they acknowledged the Phrozen’s larger build plate capacity, confirming that for serious commercial work or intricate model scaling, the resolution increase is essential, even if it comes at a higher cost.

This fidelity is particularly noticeable in scale model work. We were able to reproduce minute bolts and engine details on a 1/25th scale car body that simply failed to register on our 4K machines. As one dedicated user who prints 1/25th scale model car parts affirmed: “no other printer has consistently printed details as well as this model, even 2 years since its introduction.” This confirms our assessment: for the miniature, modeling, and jewelry segment, the 22µm resolution of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD remains the best in class under the prosumer category.

The monochrome technology contributes significantly here, not just through longevity but through speed. The efficiency of UV light transmission through a mono screen allows for drastically reduced layer exposure times. While print time is still dictated by height, the per-layer cure time is minimized, ensuring that a dense plate of small parts can be completed efficiently. We noticed a substantial decrease in print times compared to older RGB LCD printers we’ve tested. This blend of speed and resolution defines this printer’s core value proposition.

Mechanical Superiority: Double Z-Axis Guide and Laser-Engraved Build Plate

Resolution is only as good as the machine supporting it. Even the sharpest pixels are useless if the build plate shifts or vibrates during printing. Phrozen has clearly engineered the Sonic Mini 8K to mitigate these mechanical failure points, primarily through its advanced double Z-axis guide system. Resin printing involves the build plate repeatedly pulling cured layers off the FEP film at the bottom of the vat. This action—the peeling force—imparts significant stress and potential vibration onto the Z-axis rail.

By employing a double Z-axis guide, the printer significantly reduces lateral movement and rotational play. We monitored prints closely, and the movement of the build plate was exceptionally smooth and precise, layer after layer. This stability directly translates to a flawless surface finish, eliminating the ‘Z-wobble’ often seen in lesser machines. While the double rail system is excellent, we did note that it relies on precisely adjusted calibration. Phrozen explicitly mentions that the guide rails are precisely adjustable via calibration for optimized results, indicating that users should pay close attention to maintenance.

Equally important for print success is the laser-engraved building plate. We consider this a crucial detail often overlooked by competitors. Adhesion is the second biggest hurdle in resin printing after support structure failure. A perfectly flat but slick build plate often results in large prints peeling off halfway through. The laser-engraved texture provides micro-level mechanical keying, allowing the first few layers of cured resin to grip the plate firmly. We experienced near-perfect adhesion on all standard Phrozen Aqua 8k resin prints, confirming the efficacy of this design choice. The secure attachment minimizes the risk of peeling or edge deformation, particularly beneficial for long, complex prints that might otherwise fail at the 90% mark.

However, no machine is perfect, and we observed user reports regarding mechanical issues, specifically one account of the Z-axis shaft screw spinning a detached metal piece, indicating a failure in the bolts holding the mechanism together. This highlights the importance of thorough inspection upon arrival and the potential complexity of the repair process for such a precision machine. Despite these isolated reports, when the hardware functions as intended—which was our predominant experience—the mechanical precision provided by the double Z-axis and the build plate is a core competitive advantage that ensures the 22µm resolution is actually delivered consistently on the final part. This level of reliable engineering is why we recommend users investigate the structural integrity of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD.

The Resin Ecosystem and User Experience

Adopting an 8K printer means entering a specific resin ecosystem. While the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD works with standard 405nm UV resins, using 8K-optimized resins like Phrozen Aqua Gray 8k significantly enhances the clarity and fidelity of the resulting prints, as these resins contain smaller pigments optimized for the tighter pixel structure. We quickly found our optimal settings with the Aqua Gray 8k, echoing the experience of several users who reported successfully “dialing in” their favorite Phrozen resin quickly after setup.

The overall user experience, once past the initial setup, is streamlined. The USB connectivity is simple, and operating the Linux-based system via the touchscreen is intuitive. However, a small percentage of users did encounter persistent technical glitches. One detailed account described repeated failures in long prints, stopping at the last 1 or 2% with a memory card reading error that restarting could not fix. When seeking support for these issues, users sometimes face a slow, detailed troubleshooting process via email from overseas technical teams, which can be frustrating when dealing with expensive hardware failures or warranty claims. One user noted severe dissatisfaction with the manufacturer’s warranty adherence after their screen failed shortly after purchase. This mixed experience with technical support suggests that while the machine’s engineering is generally stellar, buyers should be prepared for potential hurdles if a fault develops.

Despite these caveats regarding support, the pure printing performance remains unrivaled in its class. We were able to print complex, articulated models—slugs and dragons—that required exceptional dimensional accuracy to move freely, a feat only possible with ultra-high resolution and minimal printing artifacts. This versatility, from rigid engineering prototypes to delicate articulated toys, solidifies its position as a highly capable machine. For the serious hobbyist or small business owner ready to transition to ultra-detail, the learning curve is manageable, but dedication to the associated post-processing (ventilation, washing, and curing) is non-negotiable, as detailed by multiple experienced users. This necessary secondary equipment, especially strong ventilation and a low-light workspace, is integral to maximizing the potential of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD’s performance.

The fact that one user, extremely satisfied with the detail and speed, immediately purchased a second unit highlights the addictive nature of 8K fidelity once you experience it. The reliability, coupled with speed and the ability to reproduce micro-details that were previously impossible, makes the overall workflow satisfying and highly productive, provided the individual unit is mechanically sound and the user understands the requirements of SLA printing. This machine offers a feature that truly sets it apart from the competition.

What Other Users Are Saying

Our expert assessment of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD is heavily corroborated by a consensus among users: the print quality is phenomenal, but logistical issues can arise. The praise is universally focused on the resolution. Several users confirmed that the level of detail surpasses all expectations and previous printers they owned. One individual, upgrading from a 4K machine, stated the Sonic Mini 8K “simply surpassed my expectations” and enabled them to print intricate details they could only “dream about printing before.” Another user, focused on 1/25th scale model cars, confirmed that this printer remains the “best available for under $1500” for consistently printing such fine details, noting also that Phrozen’s specialized resin minimizes fumes and scent, a significant practical advantage.

However, a balanced view requires acknowledging the serious points of friction. The negative feedback often centers around quality control and post-purchase support. We saw reports of units arriving with signs of previous use or quickly developing failures, such as non-functional screens or Z-axis mechanism problems shortly after the warranty period began. One frustrated user recounted attempting to resolve a persistent glitch that caused long prints to fail repeatedly, detailing an extensive, multi-step troubleshooting process via email from the manufacturer that ultimately failed to resolve the issue. Similarly, another user expressed deep dissatisfaction with the company’s lack of warranty adherence, having trouble getting a faulty screen replaced. These anecdotes suggest a dichotomy: when the machine works, it is arguably the best consumer-grade resolution printer available, but obtaining support for early life failures can be a significant hurdle. This necessitates careful inspection upon delivery and a readiness to troubleshoot minor software issues.

Overall, the sentiment is that if you need the absolute pinnacle of detail currently available in this form factor and price range, you buy the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD for its unmatched output, but you must be aware of the potential risk associated with technical support.

Comparing the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD to Top FDM Alternatives

While the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD is a specialist in the SLA space, prospective buyers often cross-shop it against the latest high-speed FDM (Fused Deposition Modeling) printers. These technologies serve different masters: SLA focuses on resolution and smooth surfaces, while FDM focuses on volume, strength, and speed with thermoplastic filaments. The primary competitors in the wider 3D printing market emphasize rapid production and multi-color capability, areas where resin printers inherently differ.

1. ANYCUBIC Kobra S1 Combo Multicolor 3D Printer with ACE PRO

- 【Multicolor Printing Up to 8 Colors】The Anycubic Kobra S1 Combo can achieve 4-color printing. With 2 Anycubic Ace Pros are combined, you can then unleash max 8-color printing to bring you even...

- 【Ace Pro More Than Just Active Drying】Active drying、intelligent mult-filament drying and anti-entanglement design improve the success of printing. Dual PTC heating module + 360° hot air...

The ANYCUBIC Kobra S1 Combo represents a significant divergence from the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD. This is an FDM machine built for speed (up to 600mm/s) and material versatility, featuring a dedicated multi-color system and integrated drying capabilities. The Kobra S1 Combo is ideal for users who need large, structurally robust parts, functional prototypes, or visually complex models requiring multiple colors. The build volume is also substantially larger than the compact Phrozen unit. However, even at its best, the layer lines inherent to FDM technology cannot approach the microscopic 22µm fidelity of the Phrozen machine. A user focused on miniatures, jewelry casting, or highly detailed display models where surface finish is paramount will still prefer the resin printer, while those seeking bulk, functional prints, and filament variety will lean toward the ANYCUBIC system. This comparison underscores the choice between scale/speed and unparalleled detail.

2. FLASHFORGE AD5X Multi-Color 3D Printer

- Enjoy 4-Colors Printing: With Intelligent Filament System,FLAFORGE AD5X allows your printing in 4 colors,and will be about to achieve different types of filament combinations. Features auto filament...

- Speedy and Stable: FLASHFORGE AD5X multicolor 3D printer can reach up to 600mm/s travel speed and 20m/s² acceleration, CoreXY all metal design ensures stable printing quality at high speed

The FLASHFORGE AD5X is another high-performance CoreXY FDM printer, distinguished by its 600mm/s speed, 300°C high-temp direct extruder, and All Metal CoreXY structure designed for reliability when handling advanced materials like PLA-CF and PETG-CF (carbon fiber composites). Like the ANYCUBIC, this printer caters to engineering and functional prototyping markets that require strong, heat-resistant, and chemically stable materials—areas where standard photopolymer resins struggle. The AD5X also features multi-color capabilities via IFS, expanding its visual utility without needing complex post-processing paint jobs. If a user’s primary need is high-speed batch production of industrial-grade parts or large, durable functional components, the AD5X is a compelling choice. If the priority, however, is achieving perfect, invisible layer lines and reproducing features smaller than the diameter of a human hair, the specialized 8K resolution of the Phrozen machine is the undisputed victor.

3. Comgrow K1C 3D Printer Fast Printing

- Faster and More Efficient: Creality K1C 3d printer, equips 600mm/s printing speed and 20000mm/s² acceleration, it is12 times faster than the other normal 3d printer. Give good printing experience to...

- Convenient Operation: Creality K1C is well assembled and tested before shipment. After unboxing, it is ready for plug and play. The boot-up guide is similar to that of a new smartphone. 3 minutes from...

The Creality K1C, marketed as a 2024 New Version, is designed to be a high-speed workhorse, capable of 600mm/s printing and supporting carbon fiber filaments up to 300℃. Its auto-leveling and clog-free direct extruder aim to maximize reliability and speed for FDM users. The K1C is suited for users who need rapid iteration and a sealed, reliable printing chamber for exotic filaments. It offers substantial speed improvements over older FDM technology. However, the K1C cannot compete with the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD in terms of pure surface quality and microscopic resolution. The choice between these two machines is fundamentally about detail versus deployment: the Phrozen is for museum-quality fidelity on a small scale, whereas the K1C is for rapid, functional manufacturing of components that can withstand real-world stress. For the user transitioning from FDM and finally ready to commit to supreme detail, the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD provides the resolution they crave.

Final Verdict: The Unbeatable Resolution of the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD

Our extensive analysis confirms that the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD is not just an incremental update; it represents a genuine leap forward in consumer-level resolution printing. The combination of the 8K, 7.1-inch Monochrome LCD and the subsequent 22µm XY resolution delivers microscopic details that are simply unmatched by current competitors in its category. Furthermore, the robust mechanical engineering, highlighted by the double Z-axis guide and the laser-engraved build plate, ensures this exceptional resolution is delivered consistently, minimizing print failures due to mechanical instability or poor adhesion.

We highly recommend the phrozen Sonic Mini 8K Resin 3D Printer 7.1″ Monochrome LCD for professionals (jewelers, dentists, specialized prototyping firms) and dedicated hobbyists (miniature painters, scale modelers) whose ultimate priority is microscopic fidelity and a flawless surface finish. While potential buyers should be mindful of the reported complexities regarding customer service and quality control if a fault develops, the core performance of this machine is undeniable. If you are ready to invest in the highest level of detail available in a desktop resin printer, the choice is clear.

To experience the benchmark of desktop resin printing and bring your most intricate digital models to life with unparalleled clarity, we strongly urge you to see its full feature set and user reviews today.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API