There are few things more frustrating than tackling an engine swap or major repair only to realize you lack the proper tools to safely and efficiently lift the heavy powerplant out of the chassis. I’ve been there, staring at a stubborn engine, wishing I had a simple, robust solution that would make the job less precarious and time-consuming. Having the right gear is paramount; without it, you risk damage to the engine, the vehicle, or worse, yourself.

- 【Widely use】Engine Lifting Plate Bracket Motor Engine Lifting Bracket Carb Carburetor Hoist SBC BBC Fit for Chevy Ford.

- 【Easy to use】No drilling and cutting required, just install in the right place and use.

Considering Your Needs Before Purchasing an Engine Hoist Attachment

Anyone who’s faced the task of pulling or dropping an engine knows that having a reliable method for lifting is non-negotiable. These specialized attachments are designed precisely to address that challenge, providing a secure point for your engine hoist. An ideal customer for an item like this is typically a DIY mechanic or a professional shop technician frequently working on older vehicles or common engine platforms like Chevy small block (SBC), big block (BBC), or Ford engines with carburetors or compatible intake manifolds. Someone who *shouldn’t* necessarily buy this specific type of bracket is someone working on modern fuel-injected engines that lack a carburetor flange or compatible intake bolt pattern, or perhaps someone dealing with extremely heavy or unusual engine types that require a different lifting setup. Before purchasing any engine lifting plate, consider the specific engine(s) you’ll be working on, their weight, the bolt pattern required for attachment, the material quality of the bracket, and importantly, its stated load capacity and the reputation of the welds or construction. Safety should always be the primary concern.

- 750LBS Engine Stand: With rigorous testing, it has been proven to securely hold up to a whopping 750 lb (3/8 Ton), allowing your engine is held in place safely and firmly. The upgraded H-shaped base...

- 【4400Lbs Heavy-Duty Lifting】 ✔ 2-Ton Industrial Engine Hoist – Lift truck engines, boat motors, and heavy machinery effortlessly with 4 adjustable heights (0.5T/1T/1.5T/2T). The smooth...

- Heavy-Duty Capacity: Our 1500 lbs engine stand has undergone rigorous testing to safely support up to a massive 1500 lb (3/4 Ton) load, ensuring your engine remains securely and firmly in place. The...

Introducing the lifgarfe Engine Lifting Plate Bracket

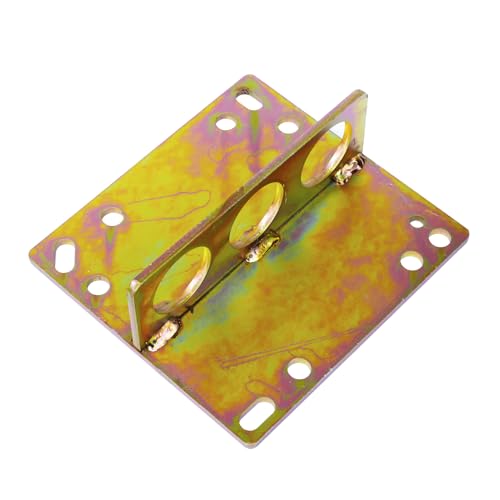

The lifgarfe Engine Lifting Plate Bracket is essentially a purpose-built steel plate designed to bolt onto the intake manifold or carburetor flange of certain engines, providing a central, balanced point for attaching an engine hoist hook or chain. It promises to simplify the often-cumbersome task of engine removal and installation for compatible engines. When you purchase it, you typically receive the bracket itself. Compared to improvising with chains wrapped around intake runners or valve covers (a risky practice!), this type of plate offers a dedicated, seemingly secure lifting point. It’s specifically aimed at the common SBC, BBC, and compatible Ford V8 engines, a significant portion of the automotive enthusiast and repair market. While its straightforward design is a plus for its intended use, it’s not suited for modern engines with complex intake manifolds or those lacking the specified bolt patterns.

Here are some potential pros and cons:

Pros:

* Designed for widely popular SBC, BBC, and Ford engines.

* Simple, bolt-on design without needing modifications.

* Claims heavy-duty steel construction.

* Color zinc coating helps resist rust.

* Provides a centralized lifting point.

Cons:

* Fitment is limited to specific engine types/intake configurations.

* Potential concerns reported regarding weld quality under load.

* May not be suitable for extremely heavy-duty or professional, daily use without thorough inspection.

* Requires removal of carburetor (if present) or access to intake manifold bolts.

Delving into Performance and Functionality Aspects

Let’s take a closer look at the key aspects and how the lifgarfe Engine Lifting Bracket functions in practice, based on its design and user experiences.

Targeted Engine Compatibility: SBC, BBC, and Ford

One of the primary selling points of this engine lifting plate is its stated compatibility with SBC (Small Block Chevy), BBC (Big Block Chevy), and certain Ford engines, particularly those with carburetor setups or intake manifolds that share a similar bolt pattern. This covers a massive range of vehicles and classic cars that are still being worked on by enthusiasts and mechanics today. The benefit here is clear: if you’re frequently dealing with these popular engine families, having a dedicated, purpose-built lifting point simplifies your workflow. Instead of trying to figure out where to safely attach chains or slings, you have a pre-designed plate that should, in theory, bolt directly into place. This saves time and reduces the guesswork involved in rigging an engine for lifting, allowing you to get on with the main task of removal or installation.

Straightforward Installation Process

The product description highlights “Easy to use” and “No drilling and cutting required, just install in the right place and use.” This implies a simple bolt-on process. Typically, these plates are designed to bolt down using existing holes on the intake manifold, often where the carburetor would sit, or other accessible bolt patterns on the intake. The benefit of this simple installation is efficiency. You don’t need specialized tools or modification skills to fit the plate. It’s designed for quick attachment and detachment. This is particularly helpful for DIYers or those who don’t want to permanently alter their engine components. The process usually involves removing the carburetor (if installed) and then using the appropriate bolts to secure the lifting plate to the intake manifold. The hoist hook or chain then attaches to the large central hole or slot on the plate. This straightforward approach means less time spent prepping the engine for lifting and more time spent on the actual repair or swap.

Heavy-Duty Construction and Material

The lifgarfe bracket is advertised as being made from “high quality, heavy duty 3/16inch steel” and coated with “colour zine to prevent rust and corrosion in bad conditions.” The use of 3/16-inch thick steel suggests a certain level of strength and rigidity, which is absolutely essential when dealing with the significant weight of an engine. A typical V8 engine can weigh anywhere from 400 to over 700 pounds, sometimes more depending on the specific model and whether accessories are attached. The material needs to be robust enough to handle these loads safely. The benefit of heavy-duty construction is supposed to be reliability and safety. A well-built plate provides confidence that your engine isn’t going to suddenly become disconnected mid-air. The colour zinc coating is a practical addition for longevity, especially in a garage environment where tools can be exposed to moisture or chemicals. This finish helps prevent rust and corrosion, keeping the bracket in good condition over time.

However, this is also where user experiences, as seen in the social proof section, introduce a critical point of concern. While the material thickness (3/16″) sounds substantial, the integrity of the finished product relies heavily on the quality of the fabrication, particularly the welds that join the lifting point to the base plate. Several users have reported weld failures under relatively moderate loads, sometimes with significant consequences like the engine dropping. This suggests that the stated “heavy-duty construction” might be undermined by manufacturing inconsistencies, specifically relating to weld penetration and strength. A lifting tool, especially one designed for such heavy loads, must have welds that are as strong as the base material itself. A weld failure can lead to sudden, catastrophic drops, posing extreme safety risks and causing damage. Therefore, while the *material specification* is promising, the *execution* of the final product’s construction, particularly the welds, appears to be a potential weak point based on some user feedback. When using any engine hoist adapter, a thorough visual inspection, especially of the welds, before *every* use is strongly recommended, regardless of the manufacturer’s claims.

Facilitating Engine Swaps and Installation

The ultimate goal of using a Motor Engine Lifting Bracket like this is to make the process of removing an old engine and installing a new one smoother and safer. Having a single, balanced lifting point makes maneuvering the engine much easier compared to juggling multiple chains or straps. The central lifting point allows the engine to hang relatively level, which is crucial when trying to align it with engine mounts or transmission splines during installation. The benefit is reduced complexity, less struggle, and potentially preventing damage that can occur from uneven lifting or scraping the engine against the vehicle’s frame or components. When it works as intended, attaching the hoist to the bracket allows for controlled lifting and lowering, making the delicate dance of aligning bolt holes significantly less frustrating. The ease with which you can connect and disconnect the hoist from this central point also speeds up the process once the engine is clear or properly seated.

Community Feedback from Users

After searching online for opinions from people who’ve used this product, I found a range of experiences, generally leaning towards positive for simple jobs, but with some critical safety concerns raised. Several users found that the lifting plate performed perfectly for their needs, describing it as effective, having a good price, and not being poorly made in terms of material feel. They reported successfully lifting engines like a Ford 302 or a Chevy 327 without issue. However, a worrying number of reviews indicated significant problems, with some reporting that the welds failed while lifting engines, even ones potentially within the bracket’s expected capacity range. These users described the bracket ripping apart or welds snapping, causing the engine to drop back into the vehicle, resulting in damage to the car and engine and narrowly avoiding personal injury. Concerns were specifically raised about the quality and penetration of the welds.

Final Thoughts on Solving Your Engine Lifting Needs

Handling engine removal and installation is a demanding task where having the right tool is essential for both efficiency and, more critically, safety. The potential complications of *not* having a secure lifting method can range from struggling awkwardly with heavy machinery to causing severe damage or injury if an engine is dropped. The lifgarfe Engine Lifting Plate Bracket offers a seemingly straightforward solution for popular SBC, BBC, and Ford engines. Its simple design and ease of attachment are appealing. When its construction holds up, it can be a convenient tool. However, the reports of weld failures mean potential buyers should exercise caution and perhaps thoroughly inspect the product upon arrival, especially the welds, before trusting it with an engine’s weight. If you need a basic lifting point for occasional use on compatible engines and are comfortable assessing its physical integrity, it might be a consideration. Click here to check the product out.

Last update on 2025-11-08 / Affiliate links / Images from Amazon Product Advertising API