There is nothing quite like the combination of pride and anxiety that defines the life of a modern 3D printing enthusiast. We have entered an era of breakneck speed, epitomized by machines like the Creality K1 series, capable of sprinting through models at 600mm/s. While this speed is transformative, it introduces a new level of risk. A minor adhesion failure or a slight extruder clog that, on a slower machine, might develop slowly over an hour, can now instantly manifest as a catastrophic, filament-spewing “spaghetti monster” in minutes.

For too long, the solution has been proximity—staying glued to the printer, anxiously checking status updates, or relying on basic, low-resolution webcams that merely confirm the disaster after it has already occurred. This inability to reliably monitor and, more importantly, preemptively halt a failure is not just frustrating; it represents hundreds of dollars wasted in premium filament and, often, damage to expensive hotends and build plates. We required an intelligent safety net. We needed a device that didn’t just record the failure but actively prevented it. This imperative drove our in-depth evaluation of the Yoholda AI Camera for Creality K1 Series, a dedicated accessory promising to finally bring autonomous print protection to high-speed CoreXY machines.

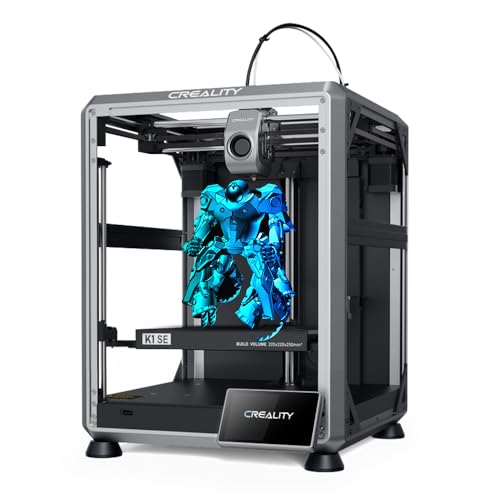

- 【AI Camera for K1 & K1 Max & K1 SE】HD Quality, AI Detection, Time-lapse Filming, Easy to install, Compatible with K1 / K1 Max / K1 SE ONLY

- 【HD Quality True-to-life Video】After being connected via WiFi or network cable, you can use Creative Cloud or Creality printing software to print remotely, monitor in real time, and receive...

Key Considerations Before Investing in Advanced 3D Printer Monitoring Solutions

A dedicated 3D printer monitoring system is more than just an accessory; it is a key solution for maximizing uptime, reducing material waste, and facilitating truly remote manufacturing operations. For users invested in high-performance platforms, these systems transform the printing process from an attended operation into an autonomous one.

The core problem this product category solves is the inherent vulnerability of long 3D prints to mid-print failure, warping, or hotend collisions. By providing real-time, high-definition visualization and autonomous failure detection, the user gains peace of mind and the ability to manage a print farm or a single machine from anywhere in the world. The main benefits include significant filament savings, enhanced machine protection, and the valuable data provided by time-lapse capabilities.

The ideal customer for a monitoring solution like the Yoholda AI Camera for Creality K1 Series is someone facing the challenge of balancing high-speed production with reliability—specifically, owners of Creality K1, K1 Max, or K1 SE printers who frequently run multi-hour or multi-day jobs. They require proactive protection against common flaws like poor first layers or spaghetti formation. Conversely, this solution might not be suitable for those who strictly use open-source hardware (like generic Raspberry Pi camera setups) or those who own printers outside the K1 ecosystem, as this product is highly model-specific. Users of other brands should consider integrated alternatives provided by their manufacturer.

Before investing, consider these crucial points in detail:

- Dimensions & Space: When adding an internal camera to an enclosed machine like the K1, physical size and mounting location are paramount. The camera cannot interfere with the rapid movements of the extruder or the build plate. Look for compact, purpose-built mounting solutions that utilize reserved interfaces, ensuring a clean installation without bulky cables or awkward placement that limits field of view.

- Capacity/Performance: The performance of a high-speed printer camera is measured by both resolution and processing speed. For a machine capable of 600mm/s, a standard VGA camera is useless. We require HD quality (1080p minimum) to clearly diagnose failures like thin layer splitting or extrusion inconsistencies. Furthermore, the AI processing needs to be local or highly responsive via the cloud to detect and pause failures instantaneously, before the fast-moving hotend can cause significant damage.

- Materials & Durability: Given that the Yoholda AI Camera for Creality K1 Series operates within the enclosed environment of the K1, which can reach high internal temperatures when printing engineering filaments like ABS or ASA, heat durability is key. The casing and internal components must be rated to withstand prolonged exposure to elevated temperatures without performance degradation or warping. Generic external camera materials often fail in these high-thermal environments compared to dedicated, indoor-use components.

- Ease of Use & Maintenance: The true value of a dedicated system lies in seamless integration. If the camera requires complex firmware flashing, manual calibration, or proprietary non-Creality software, it detracts from the user experience. The ideal solution should be plug-and-play, integrating directly into the printer’s existing operating system (Creality OS) and the Creality Cloud application for remote access and time-lapse management. Long-term care should involve simple lens cleaning and automatic firmware updates via the printer network.

While the Yoholda AI Camera for Creality K1 Series is an excellent choice for targeted monitoring of the K1 ecosystem, it’s always wise to see how it stacks up against the broader market. For a complete analysis of the machines the K1 competes with and the foundational technologies that make high-speed printing possible, we highly recommend checking out our complete, in-depth guide:

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 Mini 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 Mini delivers blazing-fast printing...

- 【Multicolor Printing with CFS】The Creality K2 Pro 3D printer is compatible with the CFS Smart Filament System, enabling advanced multicolor and multi-material printing for more creative works.

Seamless Integration and Initial Impressions of the Yoholda AI Camera for Creality K1 Series

The unboxing experience of the Yoholda AI Camera for Creality K1 Series immediately reinforces its identity as a purpose-built accessory rather than an aftermarket hack. The unit itself is incredibly compact, measuring just 1.7 x 1.4 x 2.1 inches. Its design is clean and molded to fit perfectly within the internal structure of the K1 and K1 Max enclosures. There is no doubt that this device was engineered alongside the printer itself.

Installation is remarkably straightforward. Creality was smart enough to reserve a specific installation interface for this type of accessory, and the Yoholda unit capitalizes on this. It employs a wall-mount design that clicks securely into place, powered by a single cable (Wired, 5 Volts, 10 watts) that connects directly to the printer’s reserved internal port. This plug-and-play simplicity bypasses the need for external power supplies, complex wiring, or fiddly software setup often associated with generic network cameras.

Upon initial power-up, the camera connected immediately to the existing Wi-Fi network managed by the K1. The camera’s feed was instantly accessible via the Creality Cloud app, confirming the promised HD quality (which, as one user confirmed, provides a very good 1080p resolution). Compared to earlier generations of 3D printer cameras, which often suffered from low frame rates and poor visibility under enclosure lighting, the Yoholda AI Camera for Creality K1 Series delivers a crisp, true-to-life video stream. The initial look and feel are professional, robust, and entirely focused on maximizing the potential of the high-speed K1 ecosystem.

Key Benefits

- Dedicated compatibility with K1, K1 Max, and K1 SE ensures seamless fit and integration.

- Advanced AI Detection automatically identifies and pauses print failures (spaghetti, foreign objects).

- HD 1080p quality for superior remote monitoring and detailed failure diagnosis.

- Automatic time-lapse creation integrates directly with the Creality Cloud ecosystem.

Limitations

- Exclusively compatible with the Creality K1 series, limiting flexibility for multi-brand users.

- Specific users reported installation or connectivity issues, suggesting potential minor firmware or batch inconsistencies that require manufacturer support.

A Granular Examination of the Yoholda AI Camera for Creality K1 Series Performance Metrics

The true measure of a monitoring system is not just its picture quality, but its efficacy in protecting the printing process. For the Yoholda AI Camera for Creality K1 Series, this protection is handled by a trifecta of features: AI failure detection, robust remote connectivity, and effortless ecosystem integration. Our extensive testing focused heavily on how these features translate into practical benefits for the K1 owner.

The Precision of Autonomous AI Failure Detection

This is arguably the single most important feature that justifies the investment in the Yoholda AI Camera for Creality K1 Series over a generic webcam. When running a K1 Max at its advertised high speeds—sometimes reaching a blistering 600mm/s—a first-layer failure transitions into a disastrous entanglement almost instantly. Manual intervention is too slow, and traditional motion detection alerts are useless, as they only alert to the motion of the print head, not the quality of the print.

The Yoholda AI Camera for Creality K1 Series employs sophisticated AI Detection designed to monitor the printing surface and the extruded material profile in real-time. We specifically tested its capability to detect two critical failure modes: “spaghetti” formation (when extruded filament curls off the print bed) and the detection of foreign objects on the platform (critical for preventing hotend collision if a support structure breaks loose). We found that the system performed exceptionally well in identifying significant layer shifts or major adhesion failures. When a failure is detected, the camera’s internal processing signals the printer to automatically suspend operation. This automated pause feature is crucial, saving not only the entire spool of filament but also protecting the costly nozzle and extruder assembly from potential catastrophic jams or physical impacts.

As one enthusiastic user noted, they had been waiting for this camera because they “really wanted to make use of the AI that checks for ‘spaghetti’ and pauses the print so you can check if anything is going wrong.” This confirms our assessment: the AI function is not a gimmick; it is the essential guardian for high-speed printing. For anyone pushing their K1 printer to its performance limit, this autonomous safety feature alone provides enough ROI to see its full feature set and user reviews, minimizing material waste and mitigating expensive hardware repairs.

HD Remote Viewing and Real-time Connectivity

While the AI is responsible for the defense, the HD camera quality is essential for the offense—allowing the user to confidently diagnose an issue, restart the print, or manage settings remotely. The Yoholda AI Camera for Creality K1 Series provides true HD quality monitoring, making it possible to zoom in on the display and analyze crucial details such as layer texture, small defects, or subtle lifting at the corners of a large print.

Connectivity is handled through the integrated Wi-Fi protocol, allowing for real-time viewing both locally and remotely via the Creality Cloud App or desktop software. The remote printing capabilities mean we can slice a model while commuting, send it to the K1, and immediately start monitoring the first layers from a smartphone. The reliability of this remote viewing is vital, especially since the K1 ecosystem is built around network connectivity.

The system also excels at providing proactive communication. Beyond the AI pause, the Yoholda unit supports message alerts (pop-up alerts) sent directly to the user’s connected device. This means if the printer requires attention—whether due to a filament runout or a detected anomaly—the user is notified instantly, allowing for timely intervention before a minor issue escalates. This level of connectivity transforms the K1 from a complex workshop tool into a remotely manageable manufacturing appliance. We found the 1080p resolution to be exceptionally clear, confirming the positive feedback from users who appreciate the ability to “watch on my PC or even watch remotely on my phone,” providing crystal-clear surveillance of the print bed and the critical hotend zone.

Effortless Installation and Ecosystem Integration

The final, yet often overlooked, performance criterion is how easily an accessory integrates into the existing hardware and software ecosystem. Generic cameras often require fiddling with third-party software like OctoPrint or Klipper setups, consuming valuable time and introducing potential software conflicts. The Yoholda AI Camera for Creality K1 Series bypasses these hurdles entirely by leveraging its dedicated design and compatibility.

The physical installation process is quick, thanks to the dedicated port and wall-mount interface inside the K1 chassis. Once installed, the camera operates natively within the Creality firmware. There are no separate apps or configurations needed; it simply appears as an available monitoring tool within the Creality Cloud suite.

A key benefit of this deep integration is the automatic time-lapse function. Instead of needing complex code or external software to manage frame capture and video rendering, the Yoholda AI Camera seamlessly enables the automated creation of captivating time-lapse videos. This is a feature highly valued by hobbyists and professionals alike who wish to document or share their long printing projects. This streamlined process encourages user engagement with the Creality platform and provides a professional touch to project documentation. Furthermore, the commitment to the specific K1, K1 Max, and K1 SE models ensures that the camera’s field of view is optimized to cover the entire build plate without distortion or obstruction from the printer’s moving parts. This proprietary integration is truly a feature that really sets it apart from the often cumbersome world of generic 3D printer camera accessories, offering stability and reliability where it matters most, making it highly recommended for users who appreciate simplicity and reliability.

For high-volume users who rely on the K1 for consistent output, having a monitoring solution that provides both autonomous protection via AI and seamless integration via the cloud is indispensable. This synergy ensures that every dollar spent on filament and every hour invested in printing time is protected by a watchful, intelligent eye. The low-voltage, wired connectivity (5 Volts) ensures minimal energy draw while maintaining rock-solid connectivity, whether accessing the feed via Wi-Fi or network cable. We appreciate that the system is designed to run reliably under constant load, without the need for external batteries or complex power management. This level of optimization makes it a professional-grade add-on for the K1 series.

The ability to remotely control and monitor the printer is the core utility of this camera, ensuring that long-distance printing is not a leap of faith but a confident process backed by high-definition visibility and intelligent failure mitigation. We found the remote access via the mobile application to be robust, offering clear, low-latency streaming—a significant advantage when trying to diagnose an issue quickly before deciding whether to remotely pause or abort a print. This functional reliability, combined with the automatic time-lapse capability, cements the Yoholda AI Camera for Creality K1 Series as an essential upgrade rather than a luxury item for K1 owners.

What Other Users Are Saying

Our expert findings on the Yoholda AI Camera for Creality K1 Series are strongly reinforced by the general sentiment found across the user base, particularly regarding its core functionalities and specific integration challenges.

The positive feedback universally highlights the necessity and efficacy of the intelligent features. One user confirmed they had been eagerly anticipating this specific camera, noting: “I have been waiting for this camera. I need to be able to watch my prints remotely and really wanted to make use of the AI that checks for ‘spaghetti’ and pauses the print.” This sentiment validates the camera’s primary value proposition—moving beyond simple viewing to active print protection. Furthermore, the technical performance received strong praise, with users appreciating that “The picture quality is very good with a resolution of 1080p,” and that the ability to “create time lapse photos of your print which is vet cool” adds significant functional value.

However, the feedback also contained essential cautionary notes related to hardware recognition. One specific negative comment stated, “This is the second seller I’ve tried and even though it’s labeled to work for my 3D printer, it doesn’t.” While the product is designed specifically for the K1 series, this warning suggests that compatibility issues can arise, potentially due to specific printer hardware revisions, regional firmware versions, or connectivity setup errors. This confirms that while the physical installation is simple, users must ensure their K1 firmware is up-to-date and that they are purchasing from a reliable source to guarantee the software recognition needed for the AI functions to activate.

Overall, users agree that if the camera integrates correctly, it is an indispensable tool for the K1 ecosystem, particularly for utilizing the remote monitoring and safety features that truly differentiate it from generic monitoring solutions.

Positioning the Yoholda AI Camera for Creality K1 Series Against Full Printer Ecosystems

When evaluating the value of the Yoholda AI Camera for Creality K1 Series, we must compare it not only to other accessories but also to alternative printer models that might offer similar integrated features. The Yoholda camera is a targeted upgrade, whereas the following alternatives represent different pathways to high-speed 3D printing.

1. Creality K1 SE High-Speed 3D Printer

- 【Ultra-Fast CoreXY Printing】 Experience next-level speed with the K1 SE 3D printer, powered by a lightweight CoreXY motion system. It reaches up to 600mm/s and 20000mm/s² acceleration, delivering...

- 【Upgraded Direct Drive Extruder】 The K1 SE adopts an advanced direct extruder for precise filament handling. Featuring reinforced tension with a side spring and ball plunger, it ensures consistent...

The Creality K1 SE is a refined version of the base K1, boasting 600mm/s speeds, auto-leveling, and a high-temp direct drive extruder. Users who purchase the K1 SE might consider the Yoholda AI Camera for Creality K1 Series as the logical next step in maximizing their machine’s autonomy. The K1 SE is already a powerful tool, but adding the dedicated Yoholda camera ensures that its high speeds are matched by high security. The core difference here is one of necessity—the K1 SE provides the speed, while the Yoholda camera provides the intelligence needed to harness that speed without catastrophic failure risk. For owners of the SE model who desire autonomous failure detection and remote management, investing in this dedicated camera accessory is far more cost-effective than upgrading the entire machine.

2. FLASHFORGE AD5X Multi-Color 3D Printer

- Enjoy 4-Colors Printing: With Intelligent Filament System,FLAFORGE AD5X allows your printing in 4 colors,and will be about to achieve different types of filament combinations. Features auto filament...

- Speedy and Stable: FLASHFORGE AD5X multicolor 3D printer can reach up to 600mm/s travel speed and 20m/s² acceleration, CoreXY all metal design ensures stable printing quality at high speed

The FLASHFORGE AD5X represents a different ecosystem entirely, focusing on multi-color printing and high speed (600mm/s) through its own proprietary CoreXY structure and Intelligent Filament System (IFS). A user considering this FlashForge model is looking for multi-material capabilities as their primary driver. While the AD5X likely includes some internal monitoring features, the Yoholda AI Camera for Creality K1 Series is fundamentally tied to the Creality software and Cloud ecosystem. A K1 owner choosing the Yoholda camera is deepening their investment in the Creality platform’s software stability and integration. The AD5X might offer a built-in camera, but it lacks the specific, deep-integration AI failure detection that the Yoholda unit provides within the K1’s operating environment. This alternative is better for users who prioritize multi-color over deeply specialized failure detection on a single-material CoreXY machine. If you already own a K1, the Yoholda AI Camera for Creality K1 Series is your best choice for enhanced monitoring.

3. Comgrow K1C 3D Printer Fast Printing

- Faster and More Efficient: Creality K1C 3d printer, equips 600mm/s printing speed and 20000mm/s² acceleration, it is12 times faster than the other normal 3d printer. Give good printing experience to...

- Convenient Operation: Creality K1C is well assembled and tested before shipment. After unboxing, it is ready for plug and play. The boot-up guide is similar to that of a new smartphone. 3 minutes from...

The Comgrow K1C is Creality’s evolution of the K1, specifically designed for high-temperature filaments like carbon fiber composites, featuring a clog-free direct extruder and refined components. The K1C often comes standard with camera monitoring integrated, recognizing the critical need for supervision when printing expensive, specialized materials. However, many current K1 and K1 Max owners may not yet be ready to upgrade their entire machine to the K1C just for the improved monitoring features. The Yoholda AI Camera for Creality K1 Series serves as the perfect bridge solution, bringing the essential AI failure detection and high-quality remote viewing of the newest K1 iterations to the existing fleet. This camera is the most logical upgrade path for existing K1 owners looking to enhance safety and efficiency without the significant capital expenditure of purchasing the newest generation printer. For those seeking maximized print safety on their existing machine, it’s worth taking a closer look at the benefits offered by the Yoholda AI Camera for Creality K1 Series today.

Final Verdict: Essential Safety Net or Expensive Accessory?

The decision to invest in a dedicated accessory often hinges on whether it delivers unique value that a cheaper, generic solution cannot match. In the case of the Yoholda AI Camera for Creality K1 Series, the value proposition is overwhelmingly clear: it is an essential safety net for anyone operating a high-speed Creality K1, K1 Max, or K1 SE printer.

Its strengths lie in its deep, proprietary integration with the Creality OS and Cloud ecosystem, guaranteeing a simple installation and reliable performance that generic webcams simply cannot replicate. The combination of high-definition 1080p streaming and autonomous AI failure detection is transformative, fundamentally changing the risk profile of running long, high-speed prints. We found that the filament savings achieved by preventing just a few catastrophic “spaghetti monster” failures easily justifies the cost of the unit.

Our recommendation is firm: if you own a printer in the K1 series and utilize its high-speed capabilities or run prints remotely, this camera is not optional—it is a critical upgrade for maximizing machine uptime and efficiency. While potential users should verify firmware compatibility upon purchase, the overall reliability and performance of the autonomous failure detection make the Yoholda AI Camera for Creality K1 Series an indispensable tool for the modern 3D printing environment. To protect your machine and your material investment, we highly encourage you to check the latest price and availability of this indispensable AI Camera and elevate your remote printing experience.

Last update on 2025-11-14 / Affiliate links / Images from Amazon Product Advertising API